Optical glass smelting furnace

A technology of optical glass and melting furnace, applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve problems affecting glass transparency, mechanical strength, etc., and achieve the effect of rapid melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

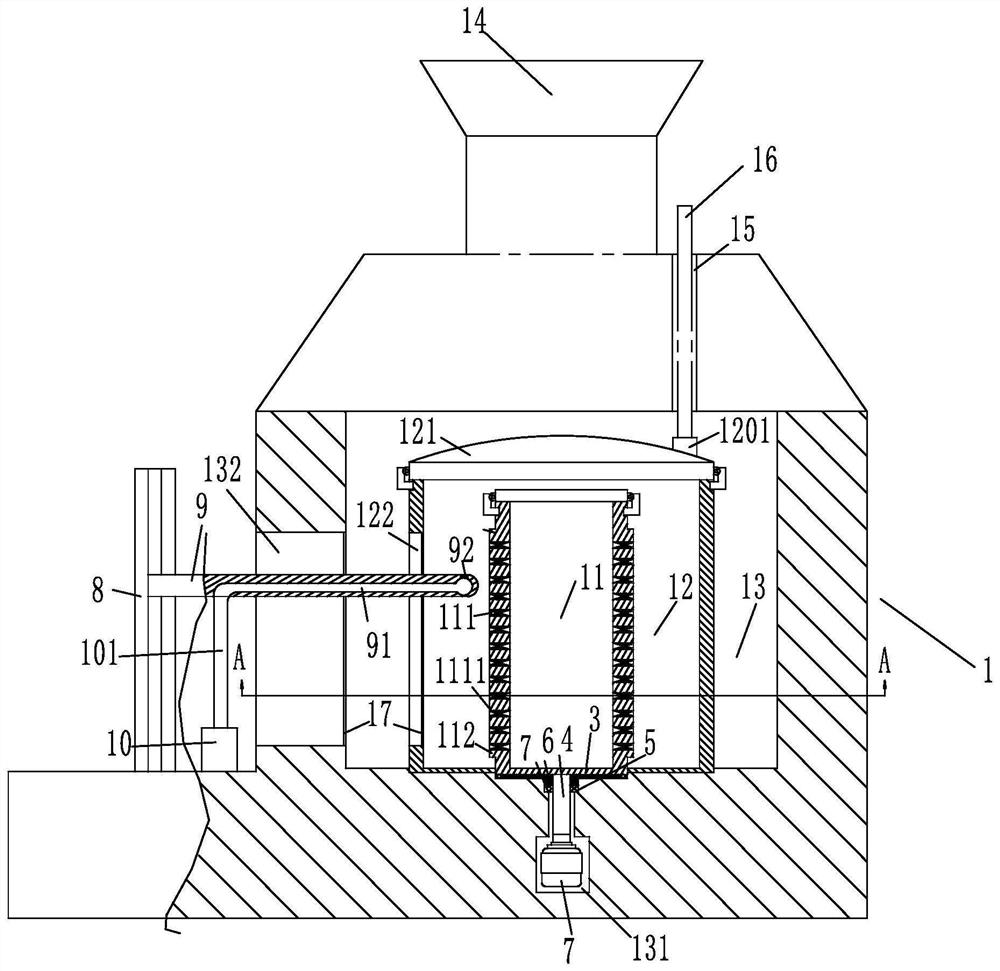

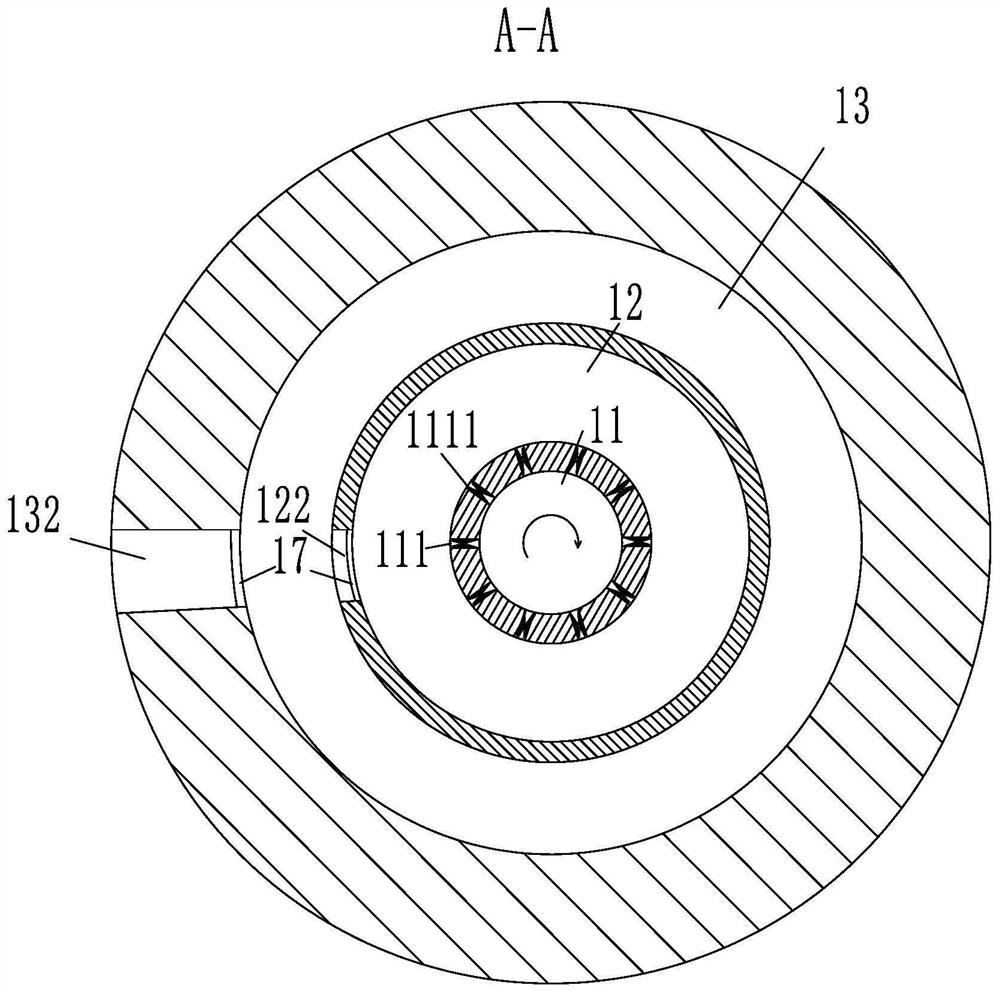

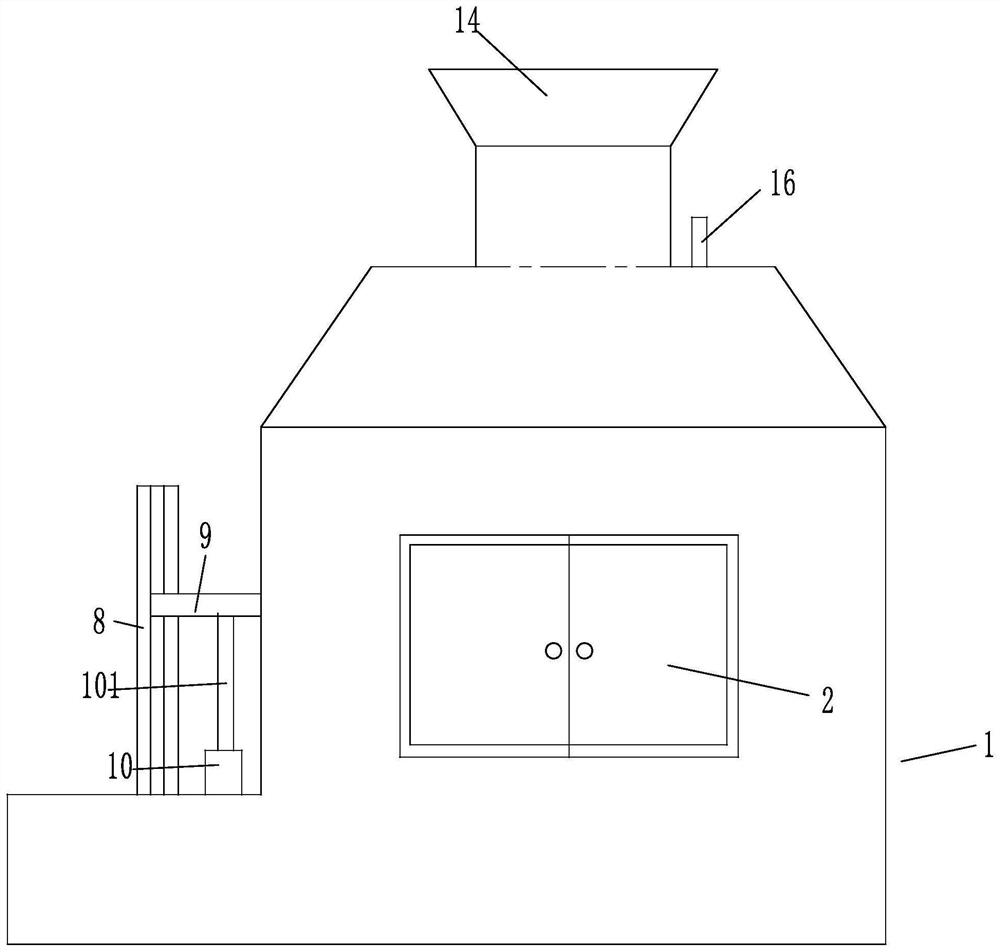

[0029] As a specific embodiment of the present invention, equidistant thorns 1111 are fixedly connected to the inner wall of the No. 1 through hole 111, and the thorns 1111 are arranged symmetrically. The steps from the outer cavity 12 to the inner cavity 11 decrease in sequence.

[0030] When the glass frit in the outer cavity 12 melts and enters the inner cavity 11 through the No. 1 through hole 111, the inner wall of the No. 1 through hole 111 is fixedly connected with equidistant thorns 1111. The thorns 1111 in the No. 1 through hole 111 will pierce the air bubbles, and The distance between the top of 1111 and the central axis of No. 1 through hole 111 gradually decreases from the outer cavity 12 to the inner cavity 11, which can pierce air bubbles of different sizes, further eliminate air bubbles, and improve the efficiency of air bubble elimination.

[0031] As a specific embodiment of the present invention, there is a No. 1 annular channel 122 on the left side of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com