Preparation method and application of AgCl glass powder with photochromic effect

A photochromic and glass powder technology, applied in the field of anti-counterfeiting, can solve the problems of poor reversibility and sensitivity, difficult fading process, hindering practical application, etc., and achieves the effects of good stability, good chemical stability and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation method based on photochromic glass powder doped with AgCl, its specific steps are as follows:

[0021] (1) First, according to the mole percentage, 15% SiO 2 -5%Al 2 o 3 -34.4%B 2 o 3 -4%ZnO-30%GeO 2 –10%SrCO 3 -1.5%AgCl-0.1%Cu 2 O, a total of 15g of the mixed material was weighed and ground for ten minutes, and then sintered at 1300°C for 25 minutes under air atmosphere to obtain transparent glass without discoloration effect.

[0022] (2) In an air atmosphere, heat the glass obtained in step (1) to 600°C, keep it warm for 1 hour, and cool to room temperature with the furnace.

[0023] (3) Grinding the glass obtained in step (2) into glass powder to obtain photochromic glass powder.

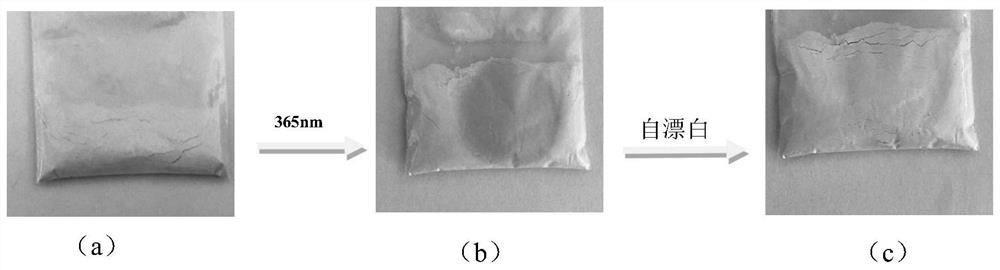

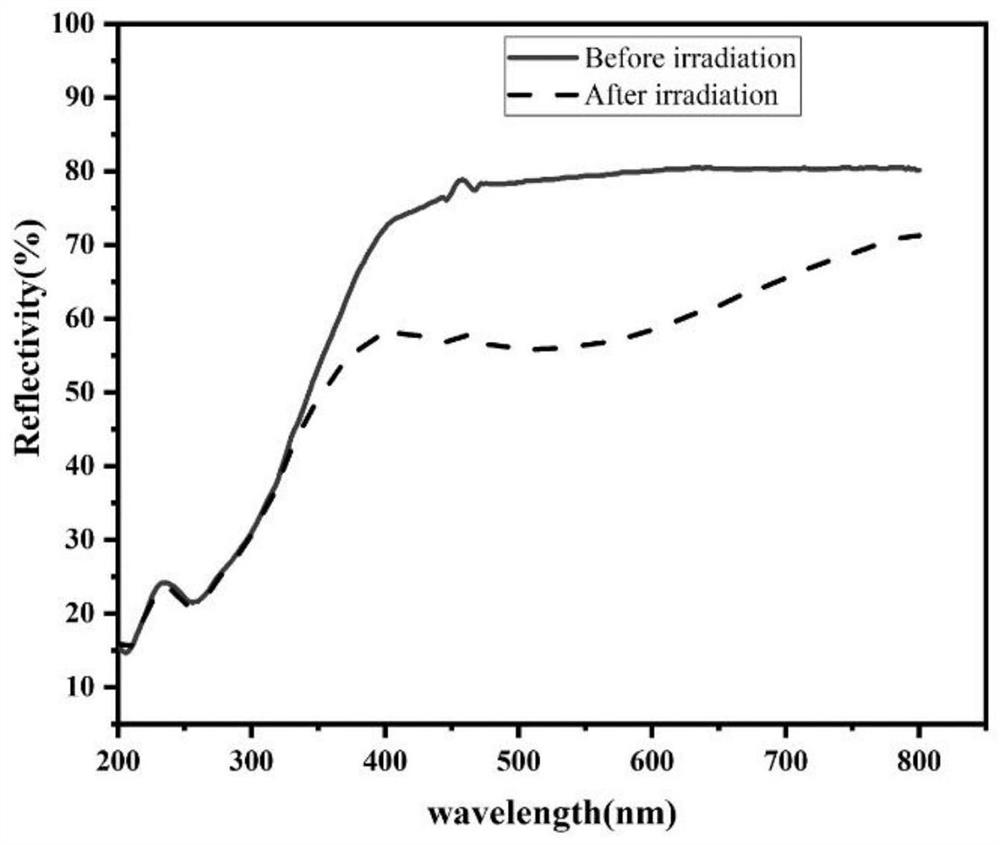

[0024] The present embodiment 1 obtains the glass frit doped with AgCl such as figure 1 As shown in (a), the glass frit kept at 600°C for 1 hour appears white. After being irradiated with 365nm ultraviolet light for 3s, an obvious color change occurred, showing b...

Embodiment 2

[0027] The preparation method of the glass powder based on photochromic AgCl, its concrete steps are as follows:

[0028] (1) First, according to the percentage of moles, 15% SiO 2 -5%Al 2 o 3 -33.9%B 2 o 3 -4%ZnO-30%GeO 2 –10%SrCO 3 -1.5%AgCl-0.1%Cu 2 O, a total of 15g of the mixed material was weighed and ground for ten minutes, and then sintered at 1300°C for 25 minutes under air atmosphere to obtain transparent glass without discoloration effect.

[0029] (2) In an air atmosphere, heat the glass obtained in step (1) to 600°C, keep it warm for 2 hours, and cool to room temperature with the furnace.

[0030] (3) Grinding the glass obtained in step (2) into glass powder to obtain photochromic glass powder.

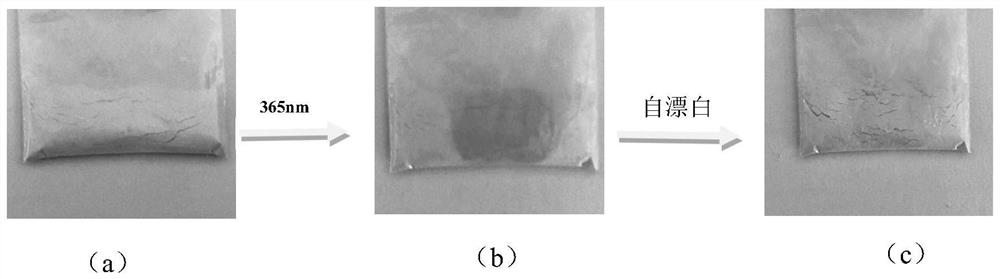

[0031] Present embodiment 1 obtains the glass frit doped with AgCl and presents white, as figure 1 As shown in (a), after being irradiated with 365nm ultraviolet light for 3s, the photochromic image is as follows figure 2 As shown in (b), it can be seen from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com