Water level buoyancy automatic drainage fuel filter

A fuel filter and automatic drainage technology, which is applied to engine components, machines/engines, liquid fuel feeders, etc., can solve the problems that water cannot be discharged directly, damage to the engine or surrounding parts, and excessive water accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings so that those embodiments can be easily realized by those having ordinary skill in the art to which the invention pertains. However, the present invention can also be realized in various forms, so the present invention is not limited to the embodiments described hereinafter. In addition, in order to describe the invention more clearly, parts that are not connected with the present invention will be omitted from the drawings.

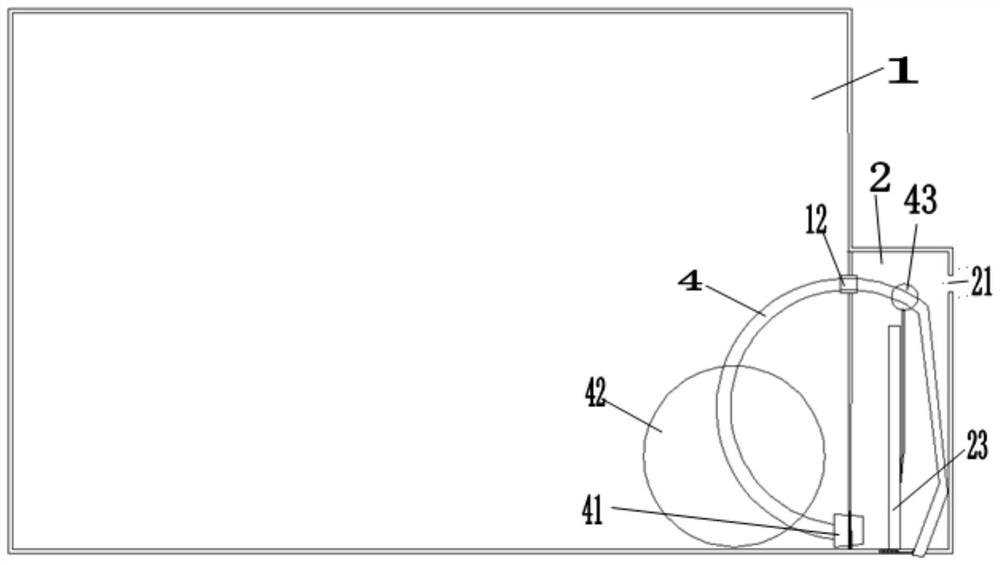

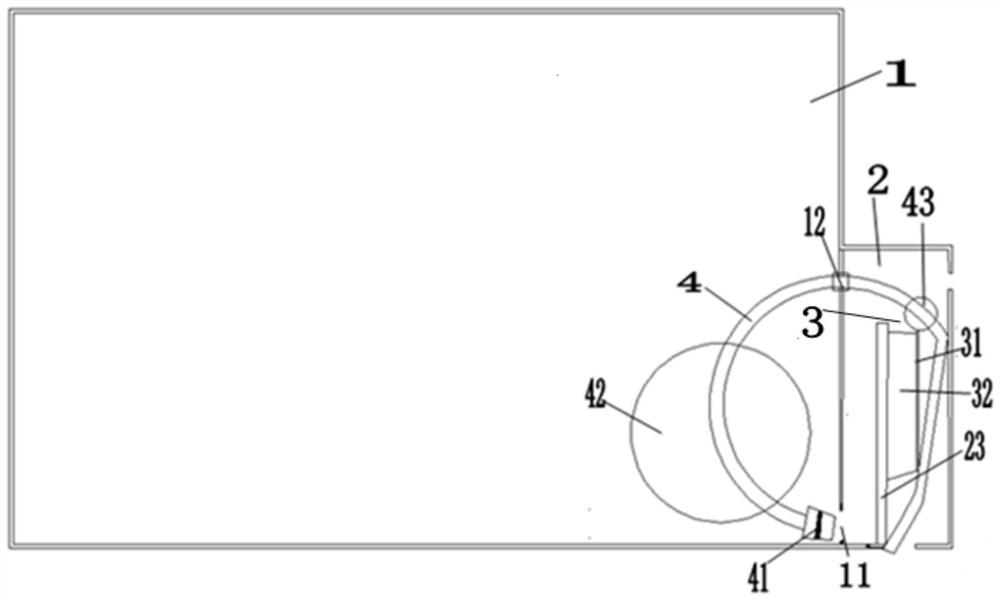

[0036] A water level buoyancy automatic drainage fuel filter, comprising: a first cavity 1, a second cavity 2, a third cavity 3, and a movable round rod 4;

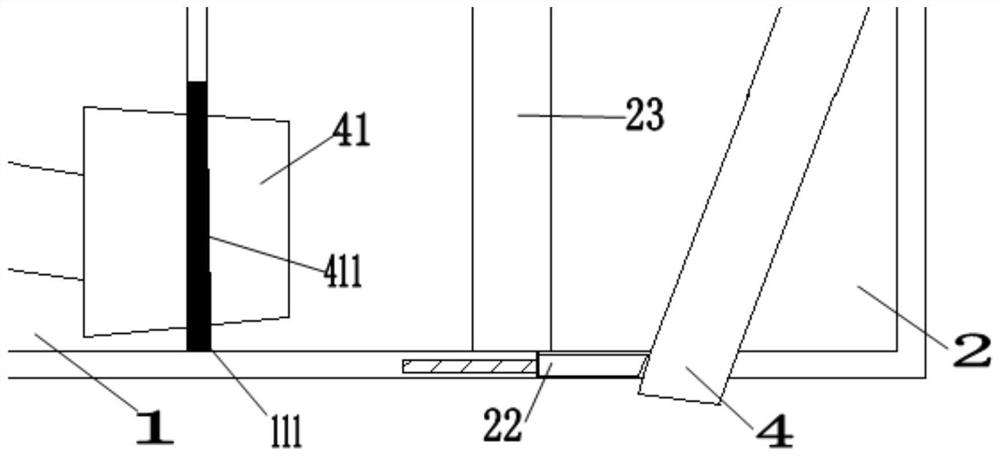

[0037] Such as figure 1 , figure 2 As shown, the first cavity 1 includes: a water outlet hole 11, a water outlet magnet 111, and a movable shaft 12;

[0038] The first cavity 1 is cylindrical, and two circular openings are vertically arranged on the cylindrical arc surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com