Compressed air cold storage system based on open type reverse Brayton cycle and control method

A technology of Brayton cycle and compressed air, which is applied in variable capacity pump parts, liquid variable capacity machines, pump devices, etc., can solve the problem of low refrigeration efficiency, achieve less power consumption parts, simple structure and cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

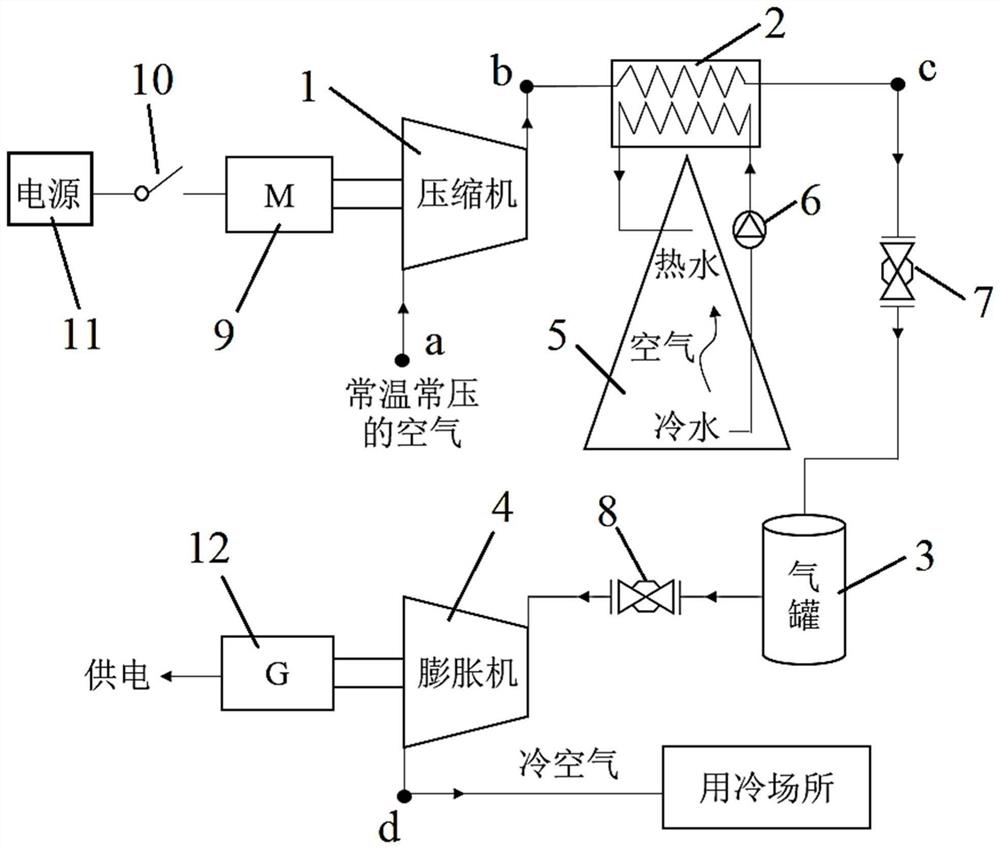

[0025] see figure 1 , a compressed air cold storage system based on an open reverse Brayton cycle in an embodiment of the present invention, including a compressor 1, a heat exchanger 2, an air tank 3, an expander 4, a cooling tower 5, a cooling water pump 6 and several valves The gas inlet of compressor 1 passes into the air at normal temperature and pressure, the gas outlet of compressor 1 is connected to the gas inlet of heat exchanger 2, and the gas outlet of heat exchanger 2 is connected to the gas inlet of gas tank 3 through first valve 7, The gas outlet of the gas tank 3 is connected to the gas inlet of the expander 4 through the second valve 8, and the gas outlet of the expander 4 is connected to a cold place; the working medium inlet of the heat exchanger 2 is connected to the cold water outlet of the cooling tower 5 through the cooling water pump 6,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap