Intelligent soot blowing control method, system and storage medium based on multi-dimensional evaluation factors

A technology for evaluating factors and control methods, applied in combustion methods, instruments, lighting and heating equipment, etc., can solve the problems of poor effect of sootblowing optimization scheme, inability to accurately evaluate the influence of the degree of contamination on the heating surface and the impact on the safe and economical operation of the boiler, etc. Achieve the effects of improving safety and economy, reducing maintenance and soot blowing labor, and reducing the risk of blowing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

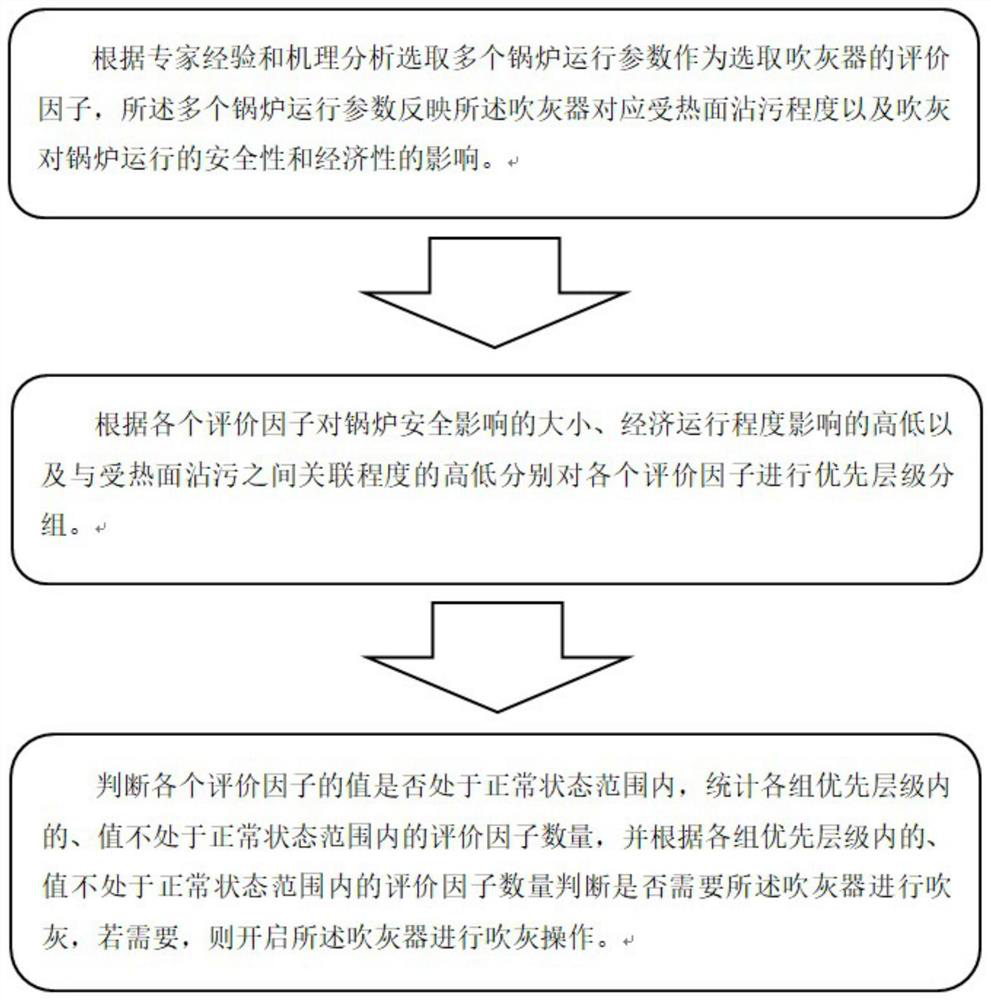

[0059] like figure 1 As shown, the present embodiment discloses an intelligent soot blowing control method based on multi-dimensional evaluation factors, comprising the following steps:

[0060] According to expert experience and mechanism analysis, multiple boiler operation parameters are selected as evaluation factors for selecting sootblowers. Multiple boiler operation parameters reflect the corresponding area of sootblower, the corresponding type of ash layer to the safety and economic operation of the boiler, and the corresponding heating surface. The effect of the degree of association of contamination;

[0061] According to the influence of each evaluation factor on the boiler safety, the degree of economic operation and the degree of correlation with the heating surface contamination, each evaluation factor is divided into priority groups;

[0062] Determine whether the value of each evaluation factor is within the normal state range, count the number of evaluation ...

Embodiment 2

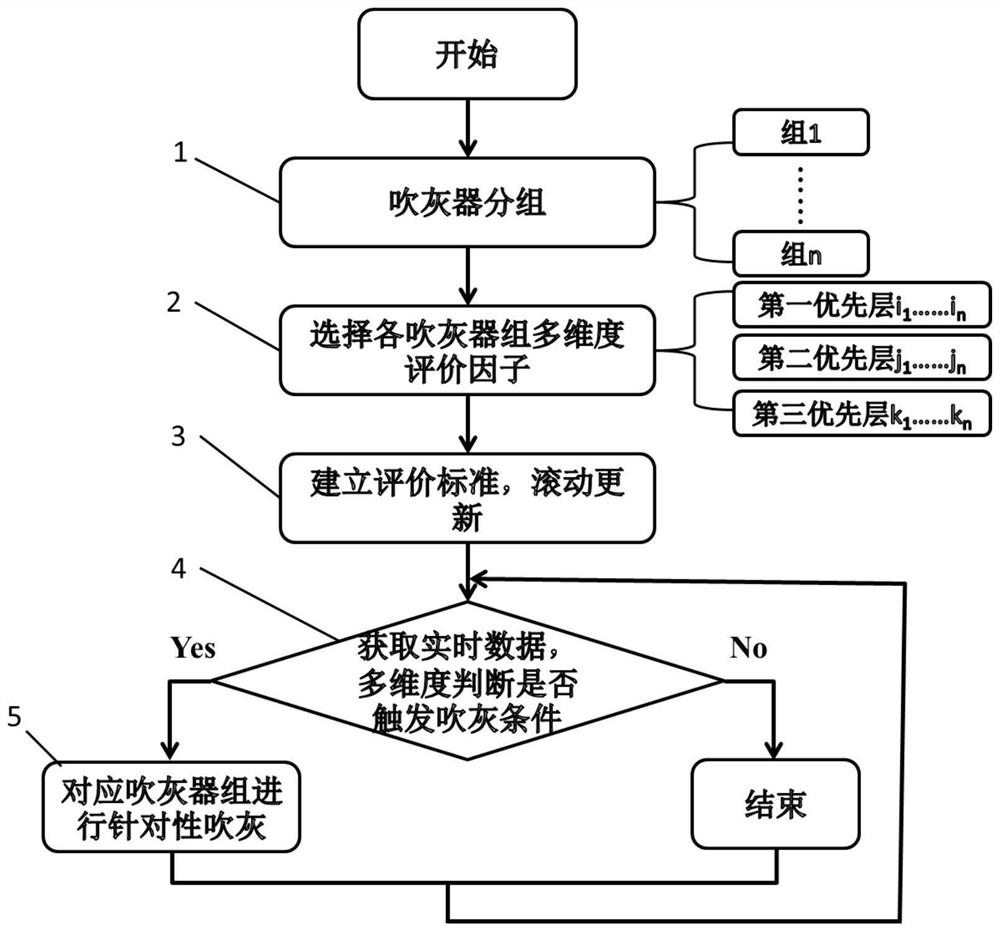

[0067] The second embodiment is a preferred embodiment of the first embodiment, and the difference from the first embodiment is that the specific steps of the intelligent soot blowing control method based on the multi-dimensional evaluation factor are refined, including the following steps:

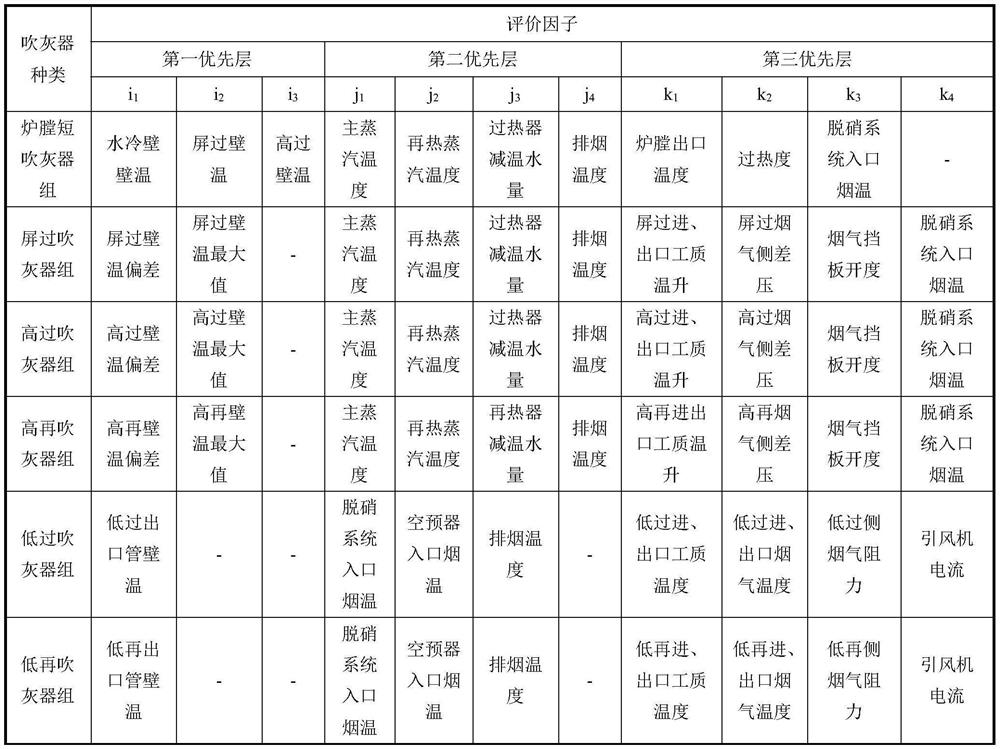

[0068] The soot blowers at different positions are used to remove the soot deposits on the heating surface of the boiler in different areas. Different boiler operating parameters can directly or indirectly reflect the soot contamination degree of different heating surfaces and the safe and economic operation of the boiler before and after soot blowing. Therefore, if In order to accurately judge the degree of soot fouling on the heating surface, ensure the safe and economical operation of the boiler before and after soot blowing by the soot blower, and control the refinement of the soot blower to blow soot efficiently as needed, it is necessary to accurately select the corresponding soot blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com