Sealing device for air preheater

An air preheater and sealing device technology, which is applied in the directions of engine sealing, lighting and heating equipment, combustion methods, etc. The gap is uniform and controllable, the wear and consumption of the fan-shaped plate or the sealing slider, etc., to reduce the wind erosion damage, improve the control effect, and increase the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

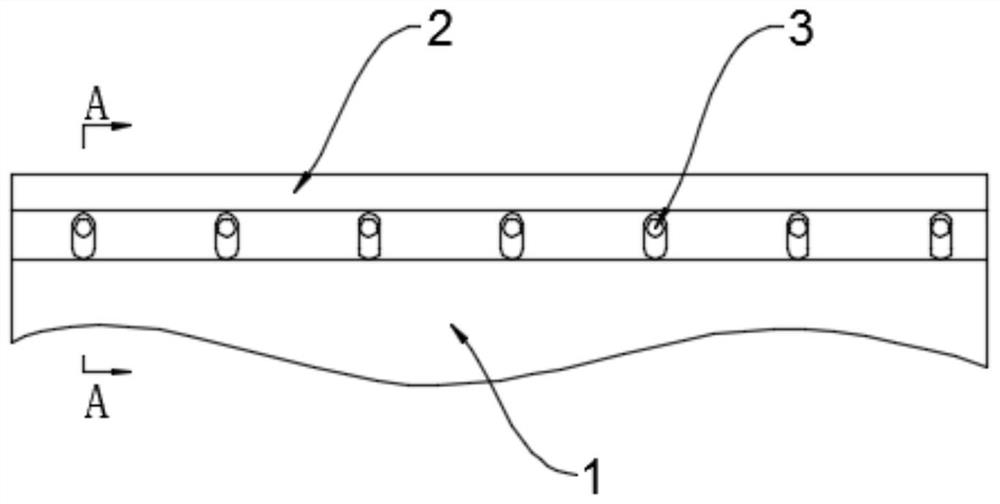

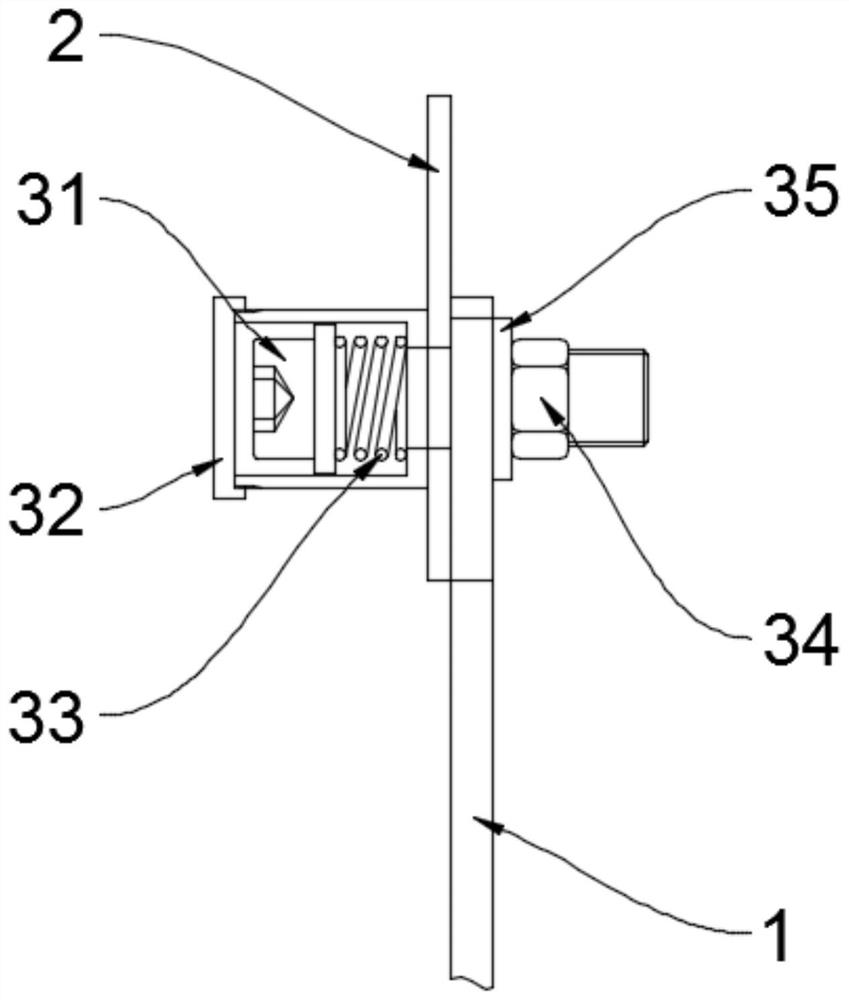

[0030] The embodiment of the present invention is realized like this, as figure 1 , image 3 A sealing device for an air preheater as shown, comprising:

[0031] Rotor bulkhead 1;

[0032] The sealing plate 2 is connected with the rotor compartment plate 1 through a plurality of soft fixing mechanisms 3, and slides relative to the rotor compartment plate 1 when the force on the sealing plate 2 exceeds a threshold value.

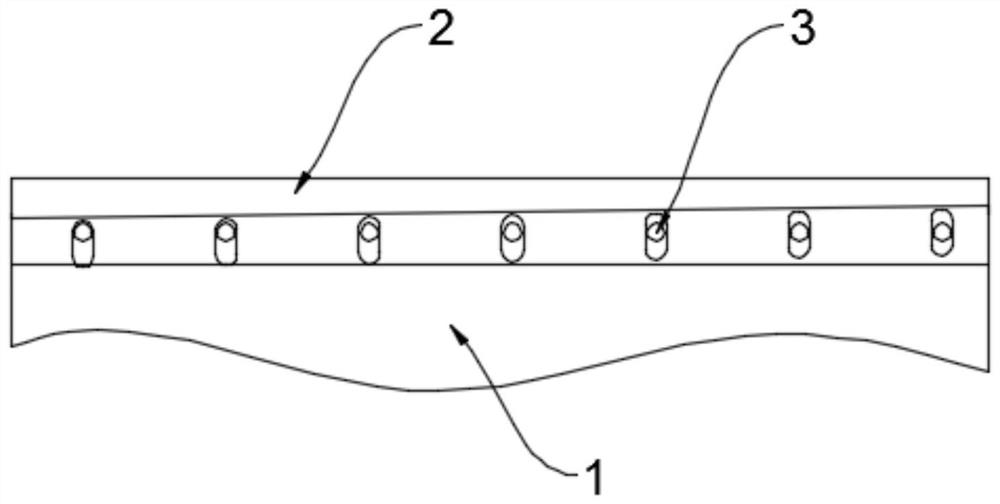

[0033] In the actual application of the present invention, the sealing plate 2 and the rotor compartment plate 1 are connected and fixed by setting the soft fixing mechanism 3, such as figure 1 As shown, in actual operation, the rotor compartment plate 1 is deformed after being heated, such as image 3 As shown, since the sealing plate 2 can slide relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com