Film positioning device for reactor pressure vessel connecting pipe welding seam inspection

A technology for inspection of welding seams and pressure vessels. It is used in reactors, nuclear reactor monitoring, measuring devices, etc. It can solve the problems of difficult cloth, high requirements and high risks, reduce the weight of equipment, facilitate transportation and installation, and ensure complete integrity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

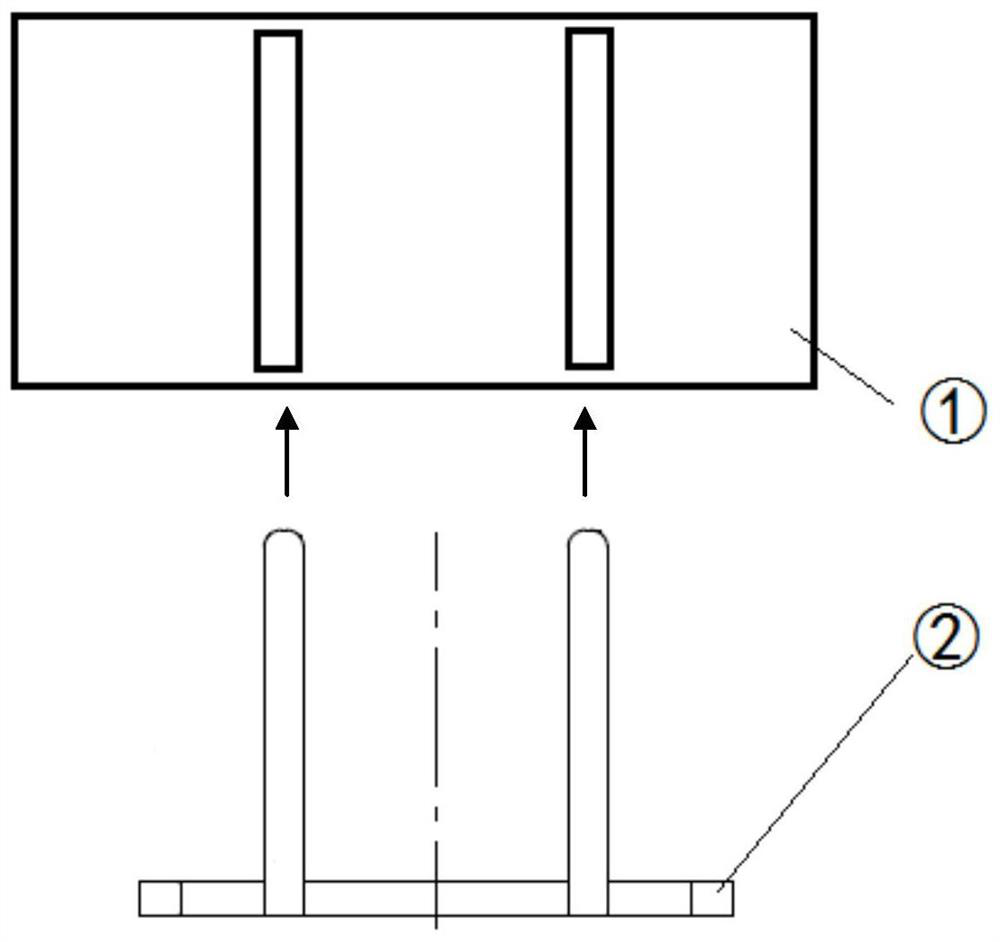

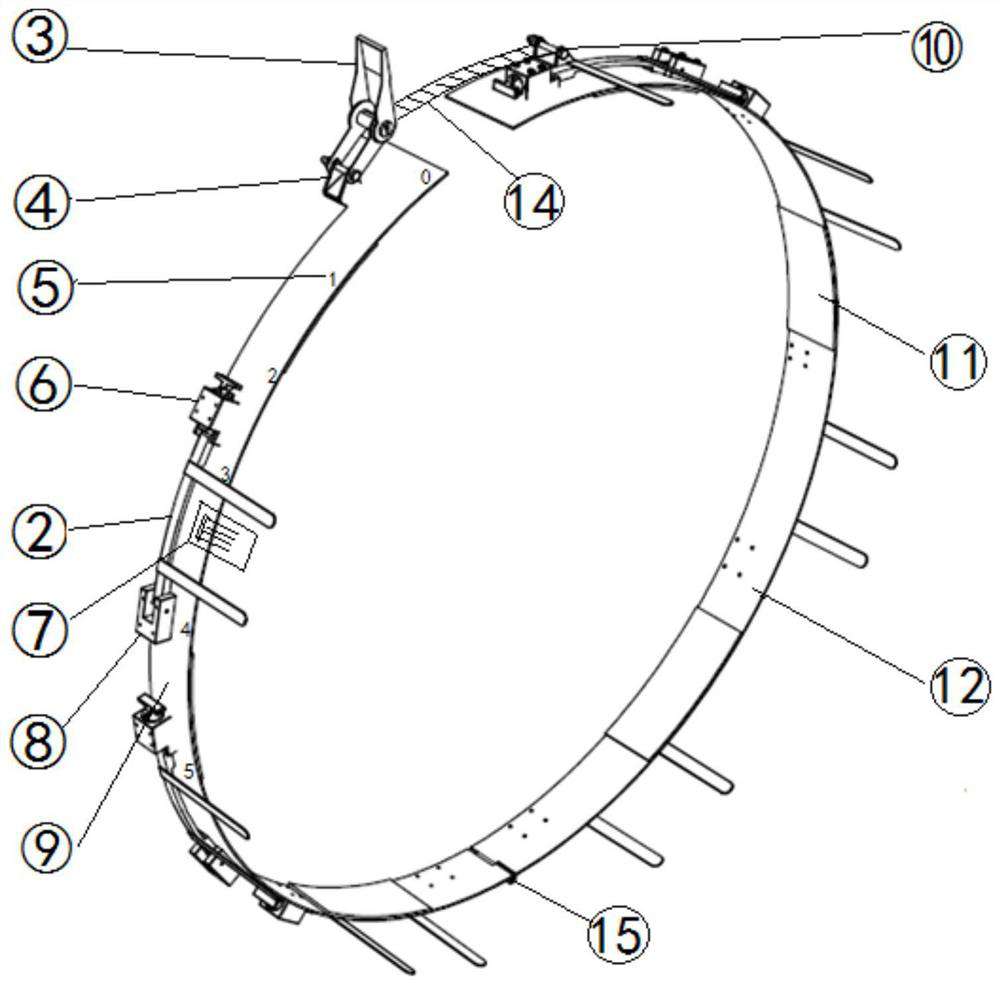

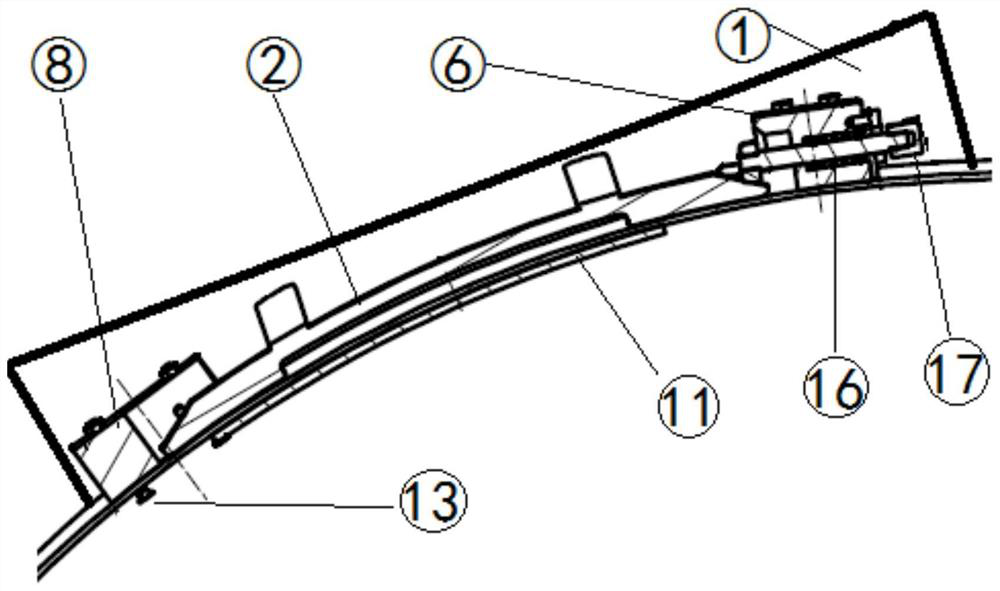

[0023] The invention provides a film positioning device for reactor pressure vessel nozzle weld inspection, which includes a film fork 2 and a film bracket. Such as figure 1 As shown, the film fork 2 and the film cassette 1 form an integral body, and the film bracket and the weld to be inspected form another integral body. Through the quick connection of the film fork 2 and the film bracket 2, the connection between the film cassette and the weld to be inspected is finally realized. precise positioning between.

[0024] The profile of film fork 2 is " not " font, is the weldment that two vertical bars and a cross bar form. The ends of the two vertical rods arranged in parallel form a semicircle so that they can be smoothly inserted into the back chute of the special cassette without damaging the cassette. The crossbar of the film f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com