Wafer cleaning device

A technology for cleaning devices and wafers, applied in cleaning methods and utensils, cleaning methods using tools, cleaning methods using liquids, etc., can solve problems such as slow soaking of cleaning liquids, long cleaning time, and reduced cleaning efficiency, etc. Achieve the effect of fast infiltration speed, shortened cleaning time and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

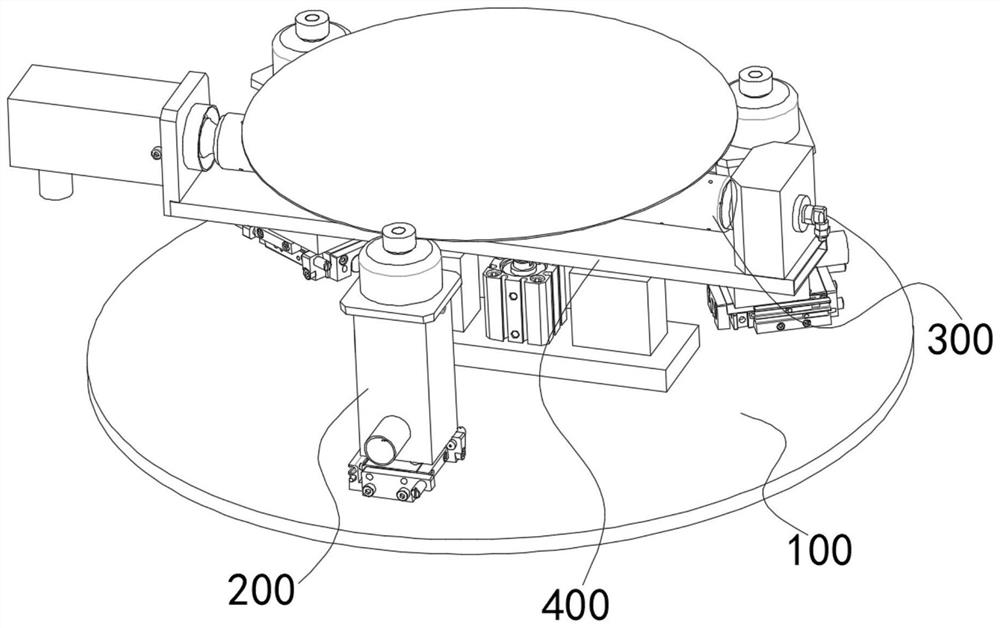

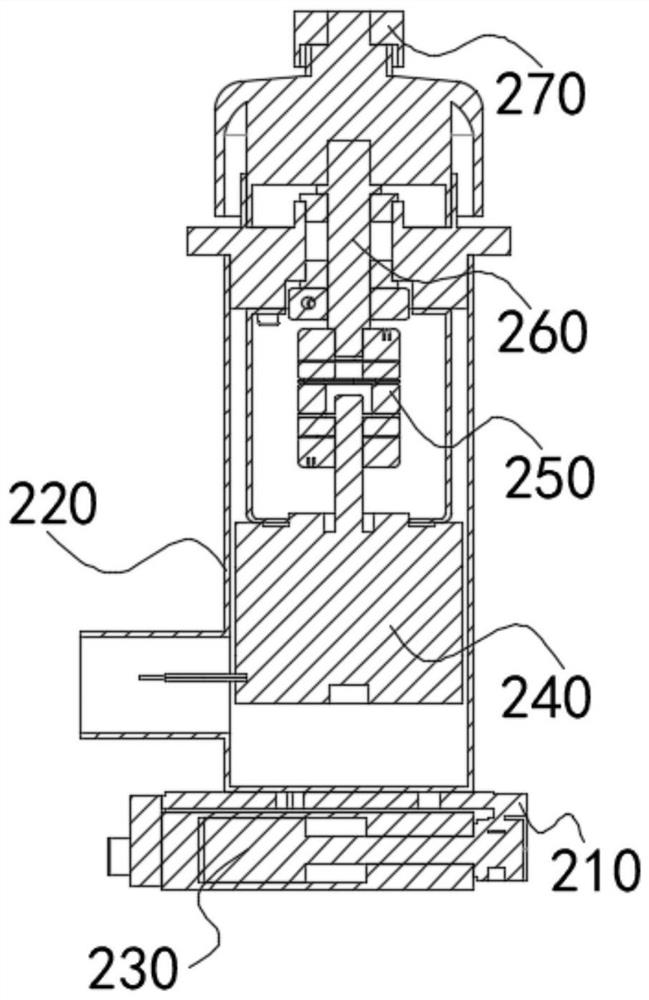

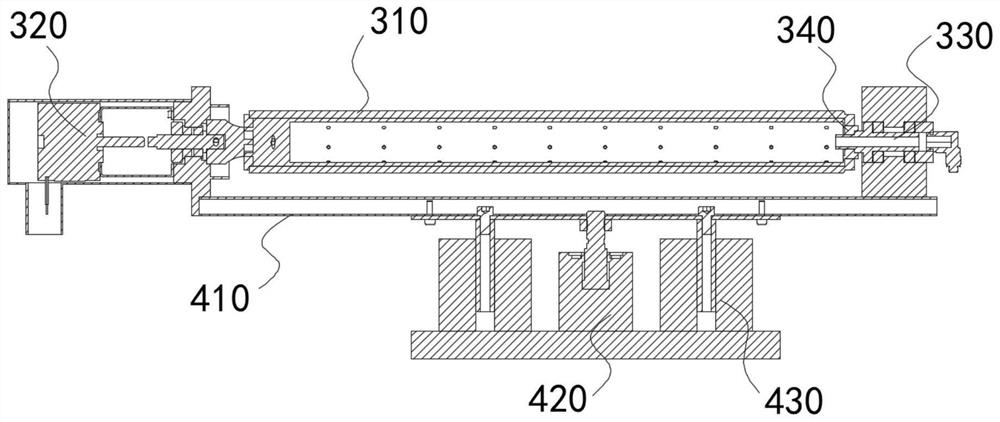

[0022] like figure 1 As shown, a wafer cleaning device in this embodiment is used to clean wafers, including a workbench 100, a rotary clamping assembly 200 and a cleaning assembly 300, wherein the rotary clamping assembly 200 is arranged on the workbench 100 and rotates The clamping assembly 200 is used to clamp the wafer and drive the wafer to rotate. The cleaning assembly 300 is attached to the wafer, and the wafer is cleaned by soaking the cleaning assembly 300. The cleaning speed is faster. More detailed explanation and illustrate.

[0023] The wafer in this embodiment is set on the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com