A low-grade copper oxide ore heap leaching and dripping process

A copper oxide ore, low-grade technology, applied in the direction of photography technology, photography auxiliary technology, process efficiency improvement, etc., can solve the problems of unbalanced leaching and recovery of raw ore, poor management and control, hindering the penetration of leaching liquid, etc., to improve leaching. Speed and leaching rate, simple laying, beneficial effect on recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

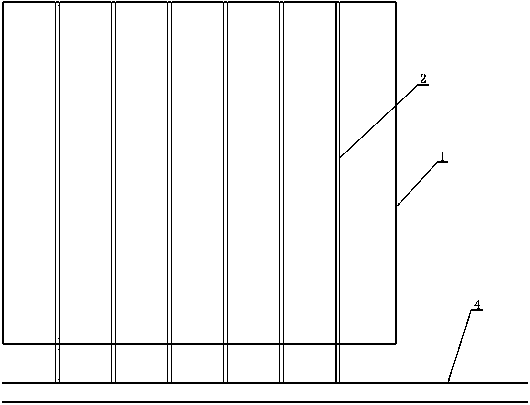

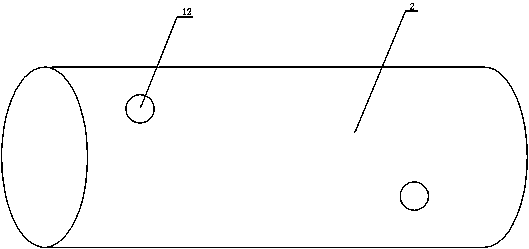

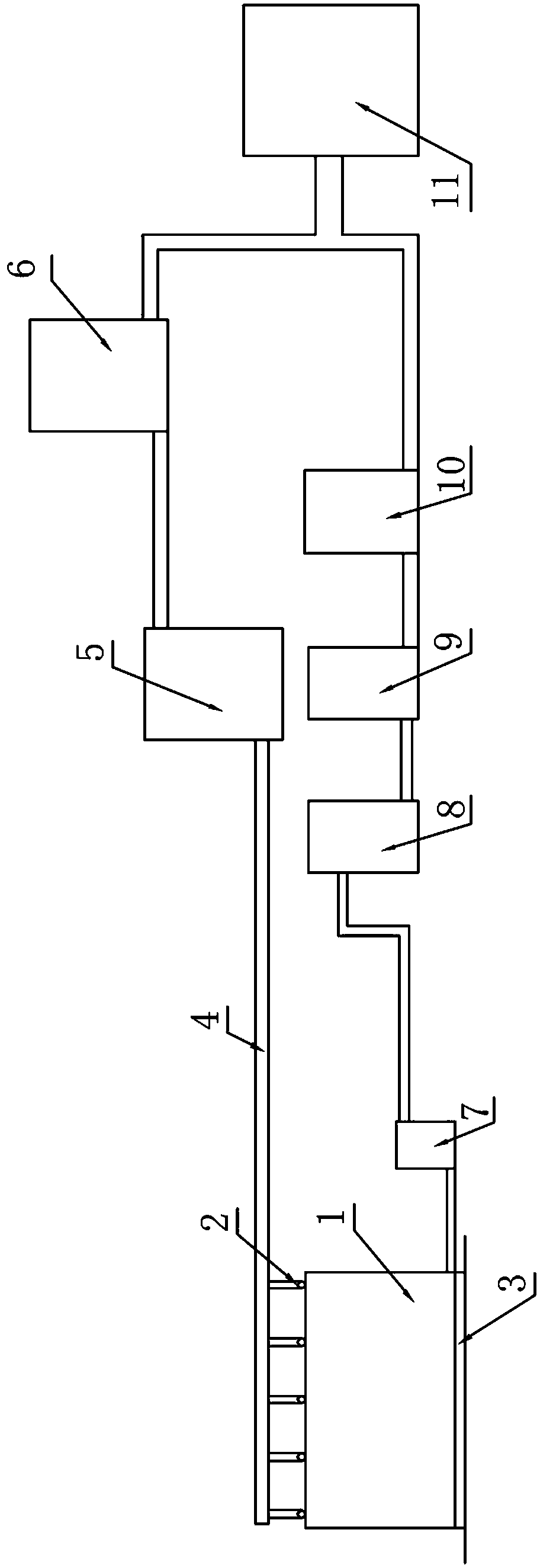

[0039] see figure 1 , figure 2 , image 3, a structural diagram of a heap leaching and dripping device for low-grade copper oxide ore, a partial structural diagram of a heap leaching and dripping device for low-grade copper oxide ore, and another part of a heap leaching and dripping device for low-grade copper oxide ore Structural schematic diagram, a heap leaching and dripping device for low-grade copper oxide ore, including dripping pipeline 2, anti-leakage pad 3, delivery pipe 4, filter 5, high-level adjustment pool 6, collection pool 7, rich solution pool 8, Extraction electrowinning device 9, barren solution pool 10 and sulfuric acid storage tank 11, said dripping pipeline 2 is laid on the surface of ore heap 1, and an anti-leakage pad 3 is arranged between said ore heap 1 and the ground, said dripping The shower pipe 2 is communicated with the conveying pipe 4, and the conveying pipe 4 is provided with twenty dripping pipes 2, and the conveying pipe 4 is communicated ...

Embodiment 2

[0050] see figure 1 , figure 2 , image 3 , a structural diagram of a heap leaching and dripping device for low-grade copper oxide ore, a partial structural diagram of a heap leaching and dripping device for low-grade copper oxide ore, and another part of a heap leaching and dripping device for low-grade copper oxide ore Structural schematic diagram, a heap leaching and dripping device for low-grade copper oxide ore, including dripping pipeline 2, anti-leakage pad 3, delivery pipe 4, filter 5, high-level adjustment pool 6, collection pool 7, rich solution pool 8, Extraction electrowinning device 9, barren solution pool 10 and sulfuric acid storage tank 11, said dripping pipeline 2 is laid on the surface of ore heap 1, and an anti-leakage pad 3 is arranged between said ore heap 1 and the ground, said dripping The shower pipe 2 is communicated with the conveying pipe 4, and the conveying pipe 4 is provided with twenty-five dripping pipes 2, and the conveying pipe 4 is communi...

Embodiment 3

[0061] see figure 1 , figure 2 , image 3 , a structural diagram of a heap leaching and dripping device for low-grade copper oxide ore, a partial structural diagram of a heap leaching and dripping device for low-grade copper oxide ore, and another part of a heap leaching and dripping device for low-grade copper oxide ore Structural schematic diagram, a heap leaching and dripping device for low-grade copper oxide ore, including dripping pipeline 2, anti-leakage pad 3, delivery pipe 4, filter 5, high-level adjustment pool 6, collection pool 7, rich solution pool 8, Extraction electrowinning device 9, barren solution pool 10 and sulfuric acid storage tank 11, said dripping pipeline 2 is laid on the surface of ore heap 1, and an anti-leakage pad 3 is arranged between said ore heap 1 and the ground, said dripping The shower pipe 2 is communicated with the conveying pipe 4, and the conveying pipe 4 is provided with fifteen dripping pipes 2, and the conveying pipe 4 is communicate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com