Component sampling and detecting device during gelatinous cosmetic filling

A detection device and cosmetic technology, applied in sampling devices, measuring devices, sampling and other directions, can solve the problems of high cost, difficult maintenance, and complicated operation, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

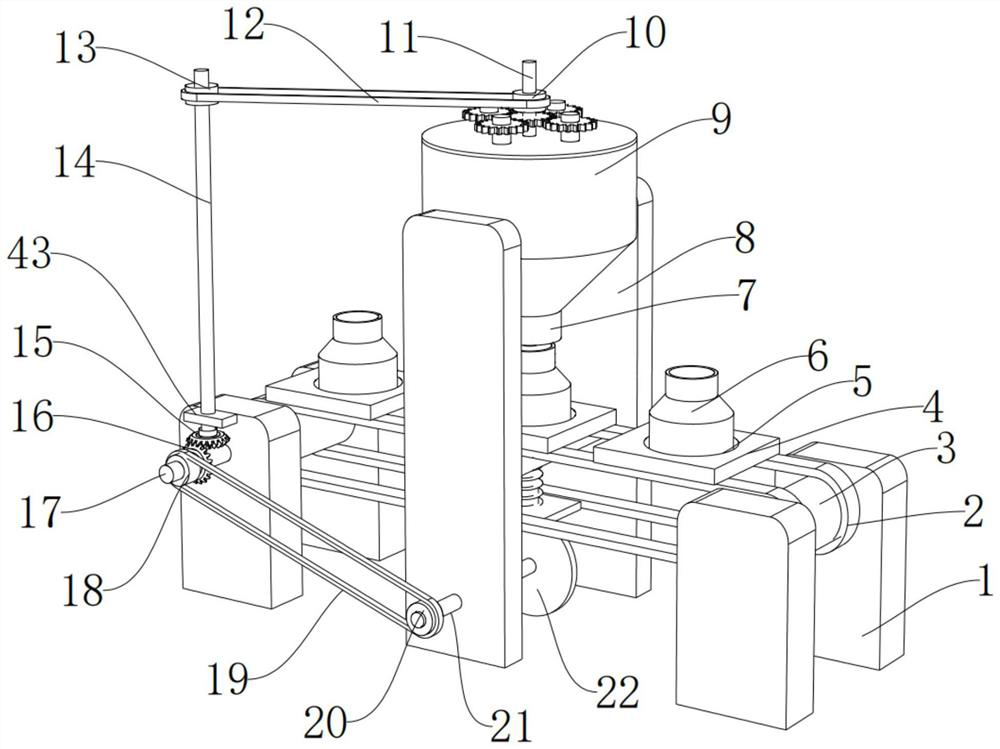

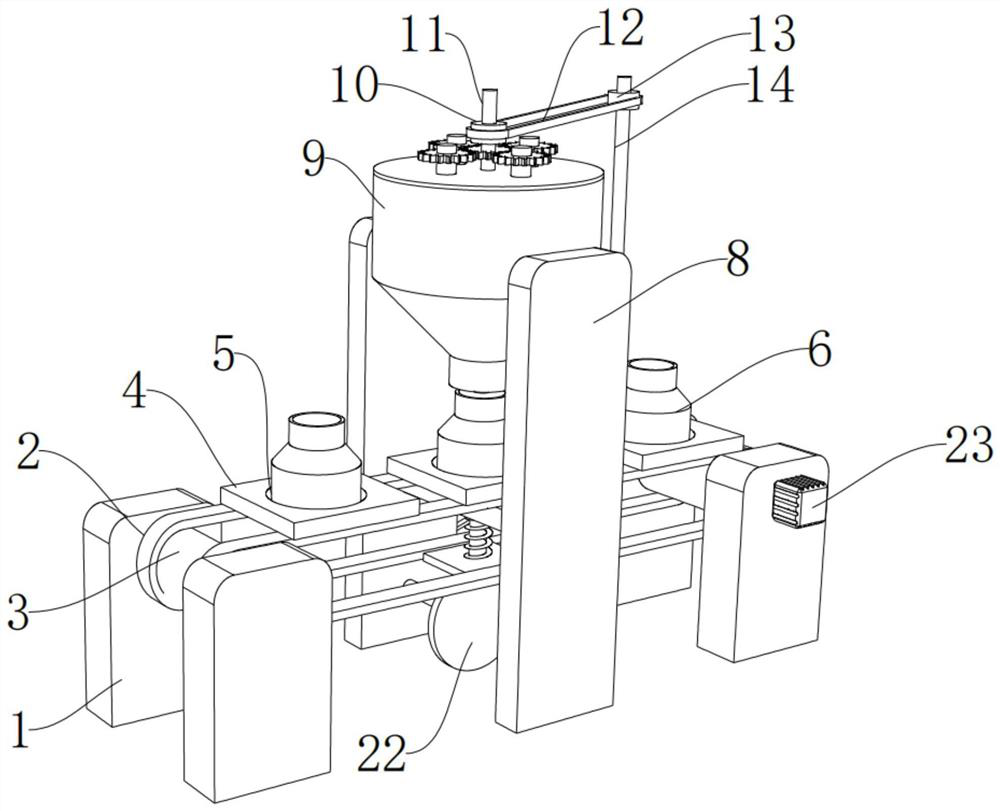

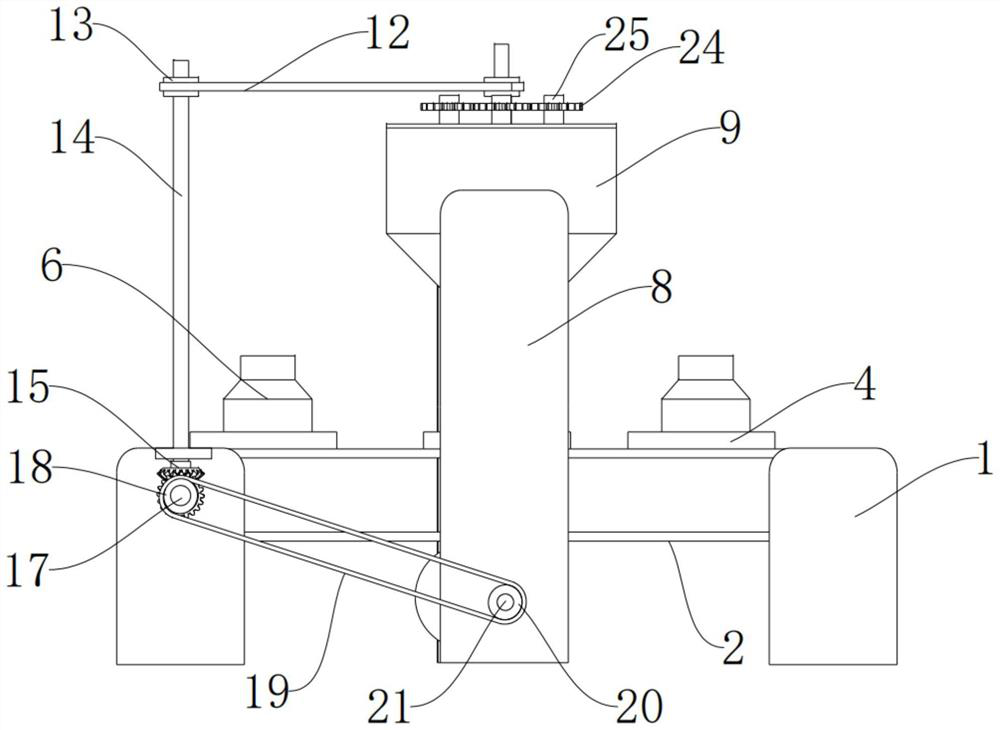

[0039] refer to Figure 1-11 , a component sampling and testing device for filling gel-like cosmetics, comprising two symmetrically arranged second fixed plates 8 and four symmetrical first fixed plates 1, the two second fixed plates 8 are fixedly connected There is the same material storage cylinder 9, the bottom of the material storage cylinder 9 is fixedly connected with an outer cylinder 7, and the inside of the outer cylinder 7 is provided with a discharge assembly for controlling the discharge, and the discharge assembly includes a first The discharge funnel 36 is slidably connected to the inside of the outer cylinder 7 with a second discharge funnel 40, and two symmetrically arranged second springs are fixedly connected between the top of the second discharge funnel 40 and the bottom of the first discharge funnel 36. 41. The inner wall of the first discharge funnel 36 is fixedly connected with four second connecting rods 39, and the ends of the four second connecting ro...

Embodiment 2

[0045] refer to Figure 1-11 , a component sampling and testing device for filling gel-like cosmetics, comprising two symmetrically arranged second fixed plates 8 and four symmetrical first fixed plates 1, the two second fixed plates 8 are fixedly connected There is the same material storage cylinder 9, the bottom of the material storage cylinder 9 is fixedly connected with an outer cylinder 7, and the inside of the outer cylinder 7 is provided with a discharge assembly for controlling the discharge, and the discharge assembly includes a first The discharge funnel 36 is slidably connected to the inside of the outer cylinder 7 with a second discharge funnel 40, and two symmetrically arranged second springs are fixedly connected between the top of the second discharge funnel 40 and the bottom of the first discharge funnel 36. 41. The inner wall of the first discharge funnel 36 is fixedly connected with four second connecting rods 39, and the ends of the four second connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com