Regeneration method of gas diffusion plate for large-generation liquid crystal screen production

A gas diffusion plate and gas diffusion technology, which is applied in gaseous chemical plating, coating, metal material coating process, etc., can solve the problems of abnormal quality of liquid crystal screen, drop, affecting the service life of gas diffusion plate, etc. The effect of foreign matter accumulation and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

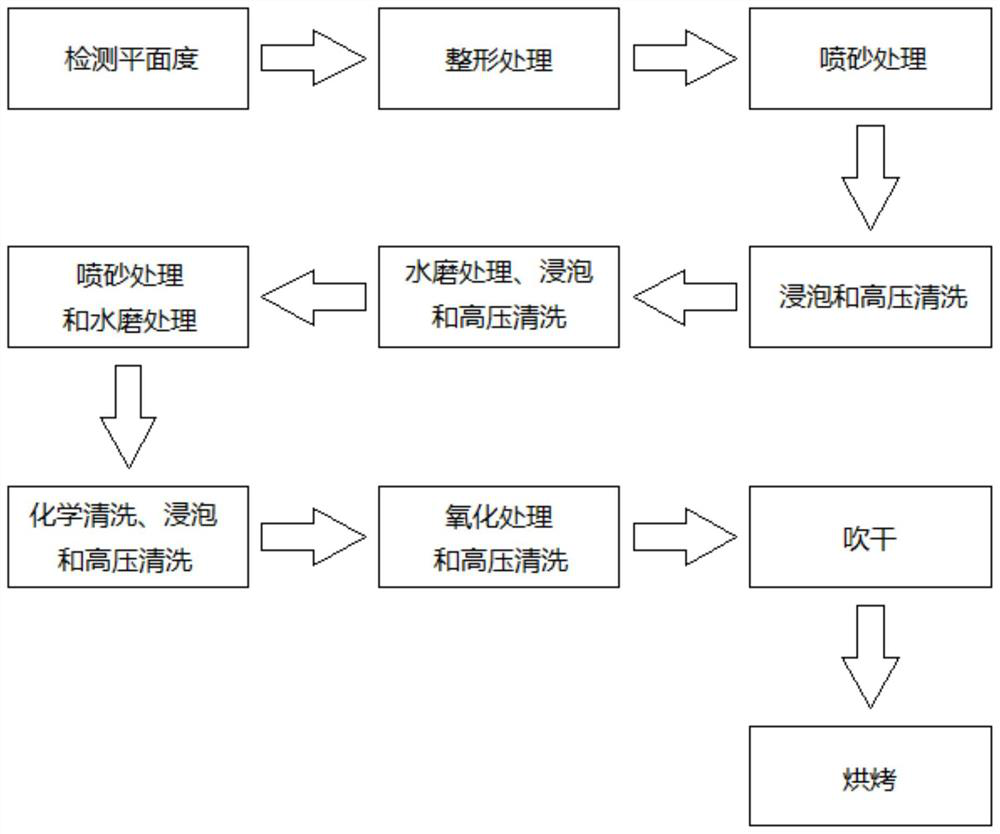

[0033] see figure 1 , a method for regenerating a gas diffusion plate for production of large-generation liquid crystal screens, specifically comprising the following steps:

[0034] S1. Put the gas diffusion plate on the platform, check the flatness of the gas diffusion plate, and judge whether the gas diffusion plate is qualified or not.

[0035] Specifically, place the gas diffusion plate on a 3m×3m×80cm marble platform (a marble platform of this size can match the size of all current gas diffusion plates), and use a laser coordinate instrument to detect the flatness of the gas diffusion plate. A total of 81 measurement points of 9×9 are uniformly selected on the gas diffusion plate, three zero point coordinates are positioned during measurement, the measurement plane is determined, and then the flatness value of the surface of the gas diffusion plate is measured, that is, 81 flatness values of different sizes are obtained. The largest value minus the smallest value is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com