Heat energy recovery, gasification and metallurgy integrated device

A technology of gasification metallurgy and heat energy recovery, applied in the field of gasification and metallurgical process equipment, can solve the problems of low efficiency, slow reaction, energy consumption and other problems in the production of molten iron, achieve good atomization effect, sufficient gasification reaction, and avoid direct erosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

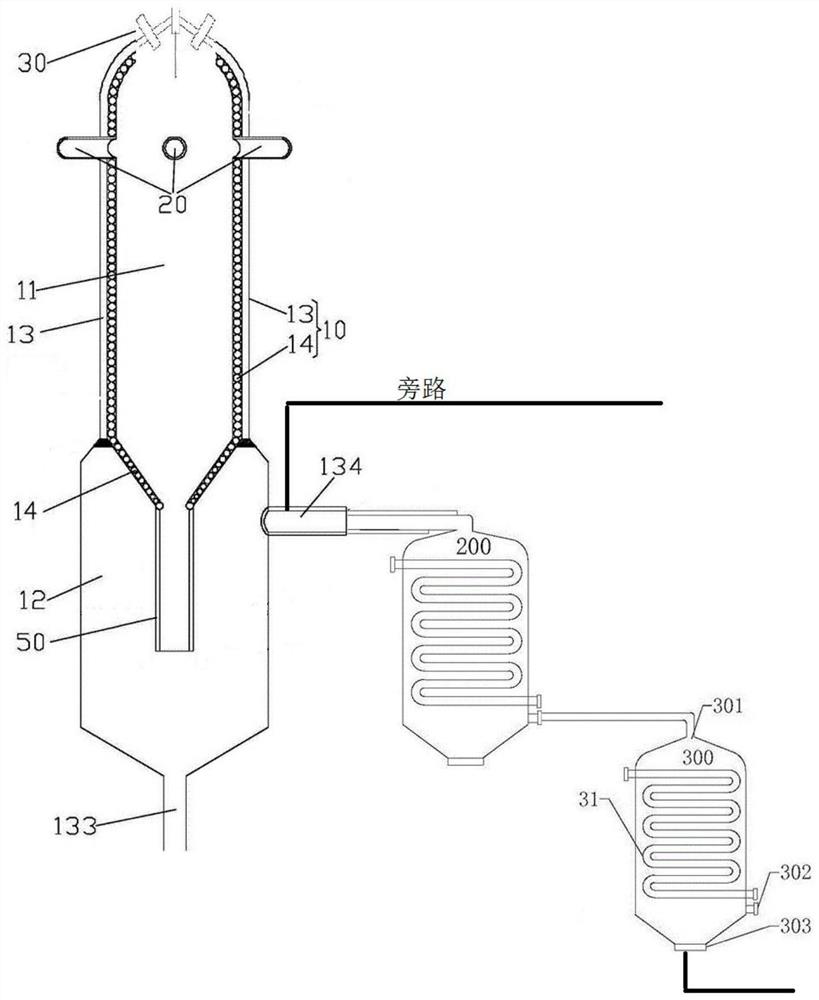

[0029] to combine figure 1 , the present invention provides a thermal energy recovery gasification metallurgical integrated device, including a gasification furnace and a waste pot, the waste pot is arranged outside the gasification furnace, and the gasification furnace and the waste pot are connected through a first high temperature resistant pipeline , the gasifier includes a shell 10 and a furnace cavity, the top of the shell 10 is provided with a pulverized coal burner 30, the middle and upper part of the shell 10 is provided with a batching burner 20, and the upper part of the furnace cavity is provided with a reaction chamber 11, The lower part of the furnace chamber is provided with a quenching chamber 12, and the reaction chamber 11 and the quenching chamber 12 are communicated through a feeding pipe 50. A first air outlet 134 is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap