Off-axis aspheric reflector zero compensation detection and correction method

A non-linear error, off-axis aspheric technology, used in measuring devices, instruments, optical devices, etc., can solve the problem of complex production, installation and use of the reference mask method, difficult to control the accuracy of nonlinear errors, and complex detection systems, etc. problem, to achieve the effect of correct face shape detection result feedback, wide adaptability, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention and the accompanying drawings. Apparently, the described embodiments do not limit the present invention.

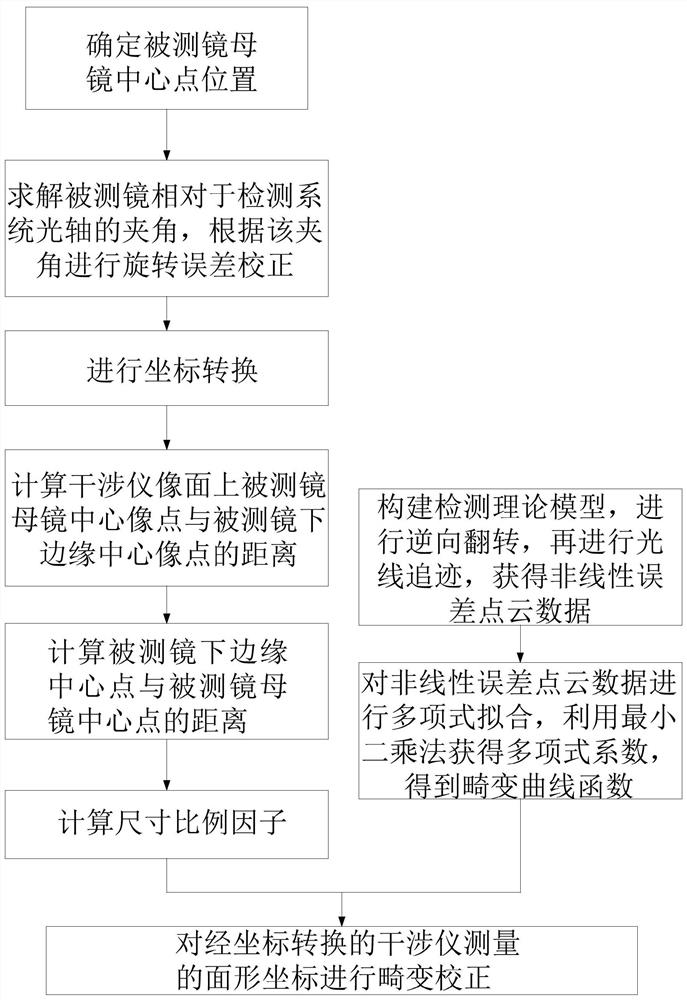

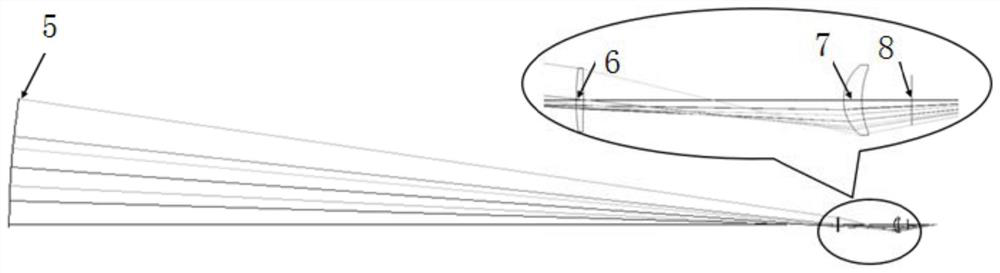

[0056] The non-linear error correction method in the zero position detection of the off-axis aspheric mirror proposed by the present invention will be further described by taking an example of detecting an off-axis aspheric mirror by an Offner compensator as follows. Among them, the specific parameters of the measured off-axis aspheric surface are shown in Table 1:

[0057] Table 1 Off-axis aspheric parameter index

[0058] Measured off-axis aspheric parameters index Mother mirror curvature radius R -2041.718mm quadratic coefficient K -9.408 off-axis 146mm Dimensions (W*H) 280*170mm Surface accuracy (λ=632.8nm) PV≤λ / 7, RMS≤λ / 50

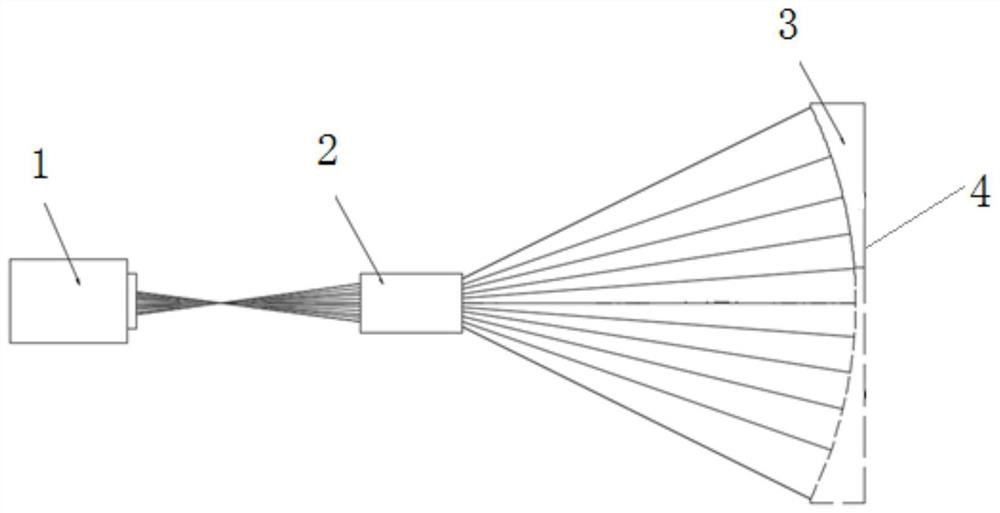

[0059] Such as figure 1 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com