Vertical wall surface two-degree-of-freedom positioning system with adjustable vertical automation degree

A positioning system and automation technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of multi-manpower and construction period, high structural requirements, large strokes, etc., and achieve the effect of improving measurement accuracy and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

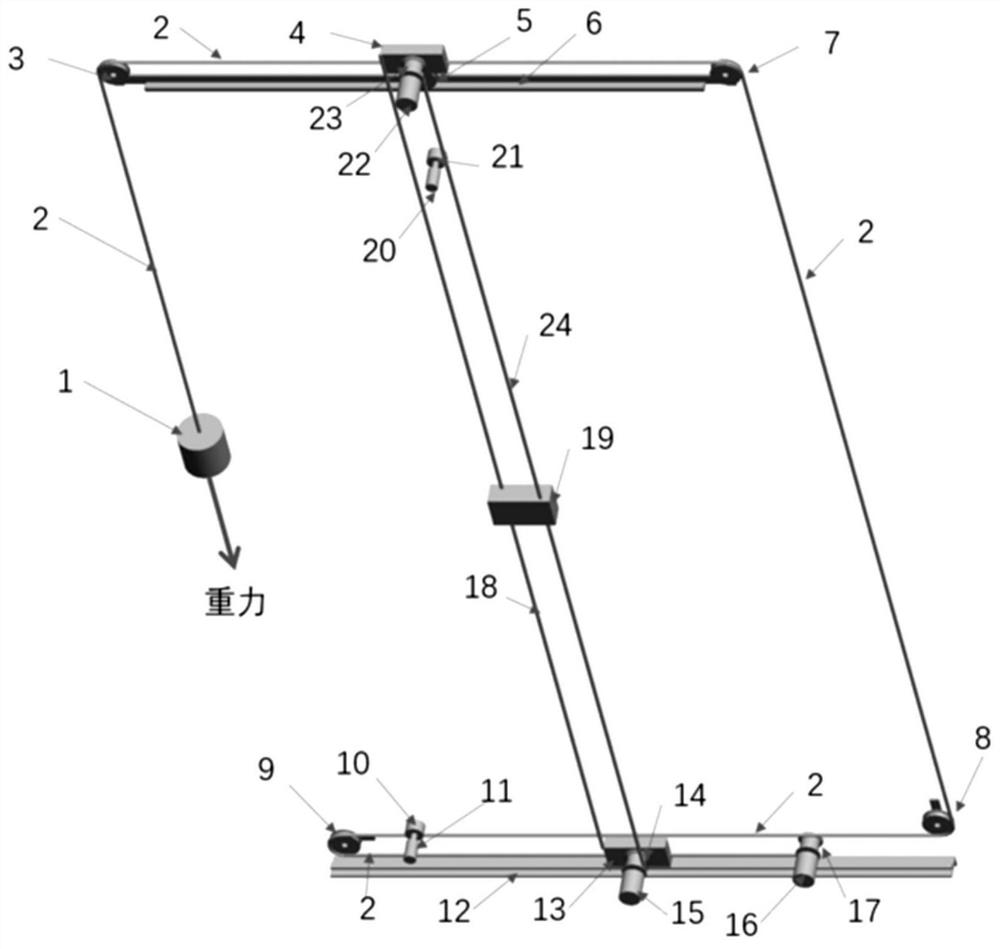

[0035] The present invention provides a vertical wall two-degree-of-freedom positioning system with adjustable vertical automaticity, which includes a lateral movement system 100, a vertical movement system 200, and an encoding assembly 300. The vertical movement system 200 is slidably connected to the lateral movement system 100. The encoding component 300 measures the moving positions of the lateral movement system 100 and the vertical movement system 200 respectively. It can be applied to the occasion requirements of different strokes and has strong applicability.

[0036] The lateral movement system 100 includes a gravity block 1, a first flexible traction rope 2, a block pulley 101, a guide rail set 102, a sliding set 103, and a first winch assembly 104; At both ends of the group 102, the sliding group 103 is adapted to slide on the guide rail group 102, the first flexible traction rope 2 passes through and is fixed on the sliding group 103, one end of the first flexible ...

Embodiment 2

[0046] This embodiment 2 is completed on the basis of embodiment 1, which is a preferred embodiment. specific:

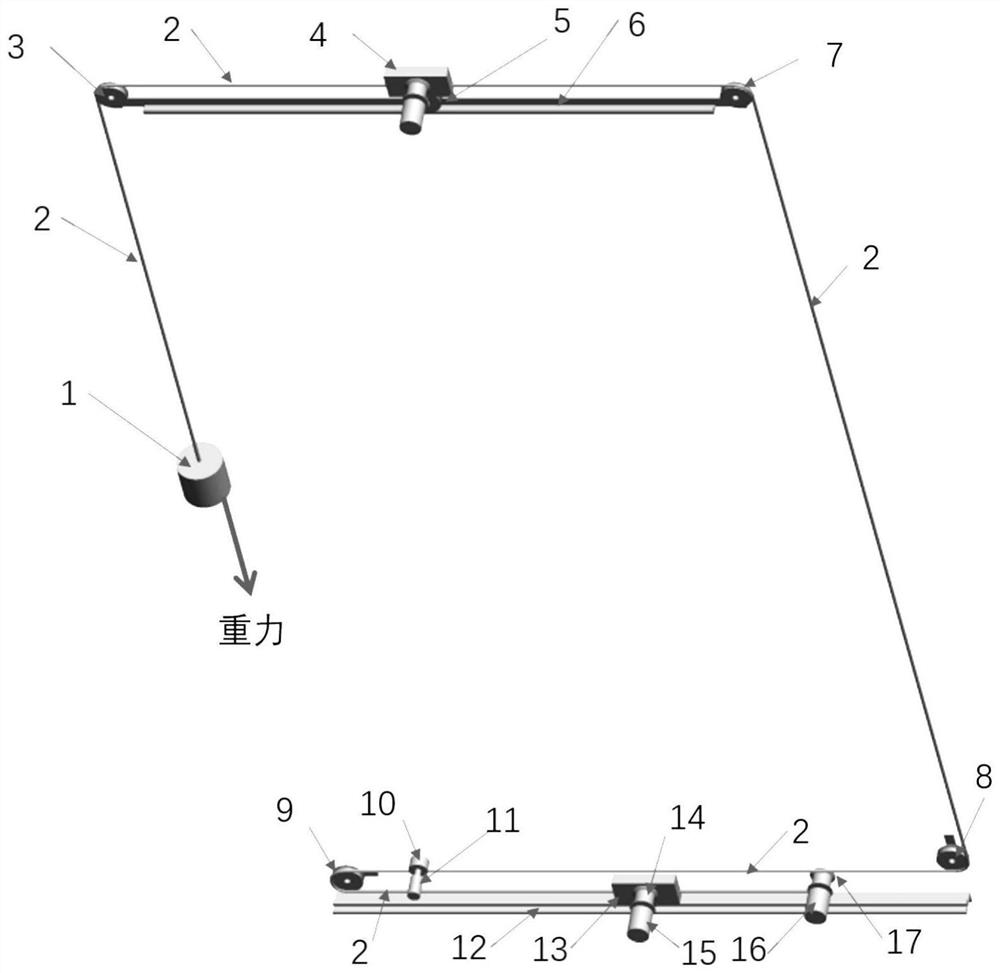

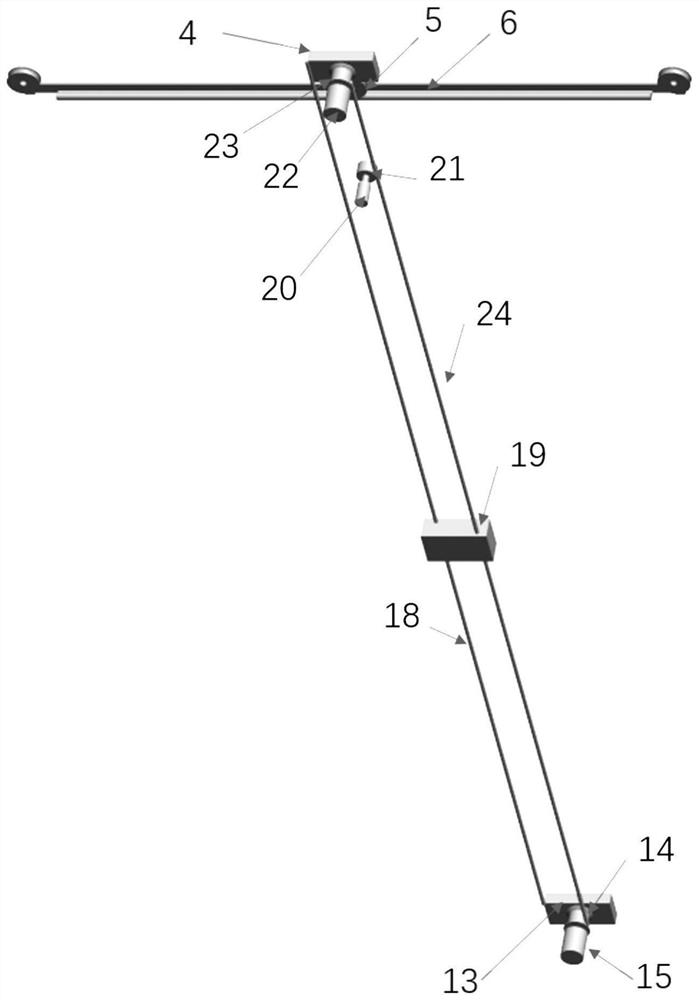

[0047] Such as figure 1 As shown, the slide rail 6 and the linear track 12 are arranged in parallel. The mounting block 4 slides on the slide rail 6 through the mounting block roller 5, and the two ends of the slide rail 6 are respectively provided with a first pulley 3 and a second pulley 7. A linear track slider 13 suitable for sliding is provided on the linear track 12, and a third pulley 8 and a fourth pulley 9 are respectively provided at both ends of the linear track 12. The mounting block 4 and the linear track slide block 13 are connected by a guide post 18 perpendicular thereto.

[0048] The third winch 23 is installed on the mounting block 4, and the third winch 23 is driven by the third winch motor 22; drive. Both ends of the second traction soft rope 24 are respectively wound on the second hoist 14 and the third hoist 23 , and the middle of the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com