Device and method for testing correlation between bolt tightening times and corrosion resistance

A test device and related technology, applied in the direction of measuring device, measuring torque/torsion force during tightening, testing of mechanical parts, etc., can solve problems such as increasing the risk of vehicle collision, weakening of steering assist, corrosion and fracture of bolts, etc. The effect of reducing development complexity and reducing development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the purpose, technical solution and advantages of the invention clearer, the invention will be further elaborated below in conjunction with the accompanying drawings.

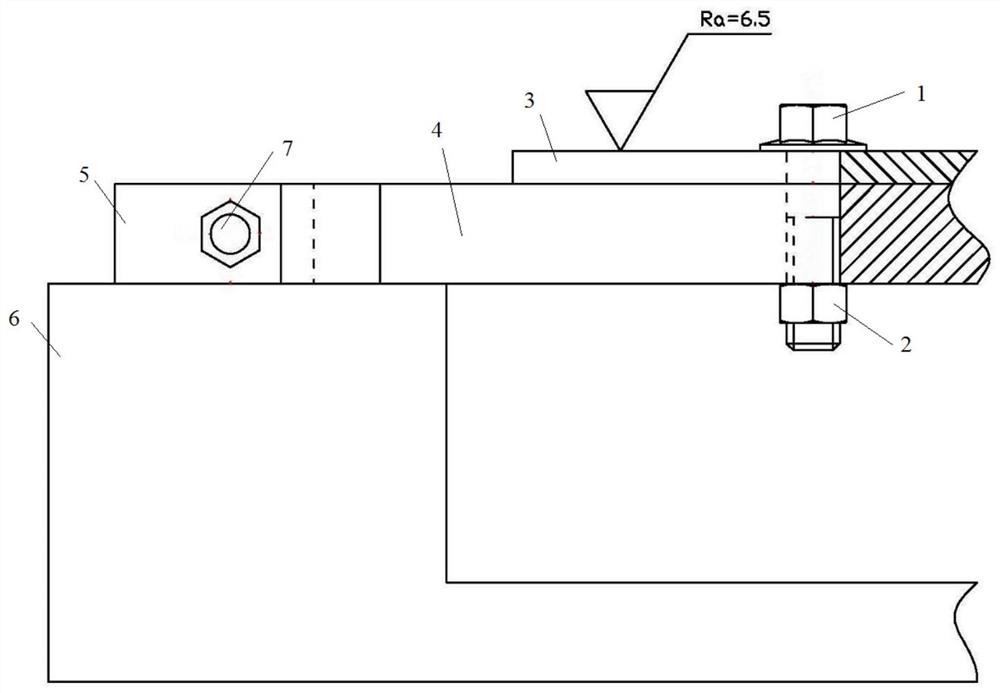

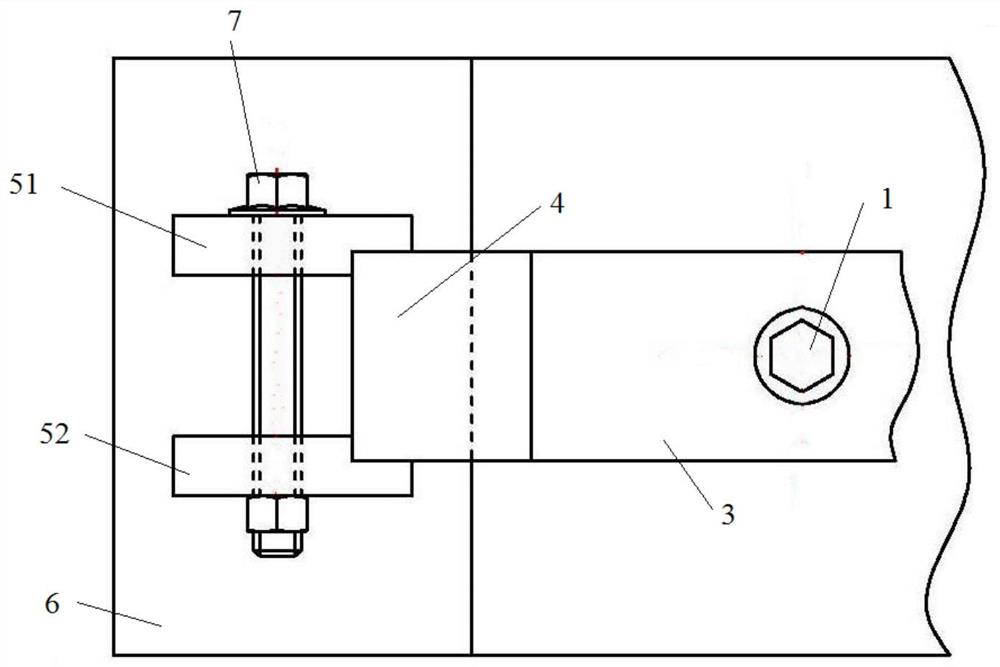

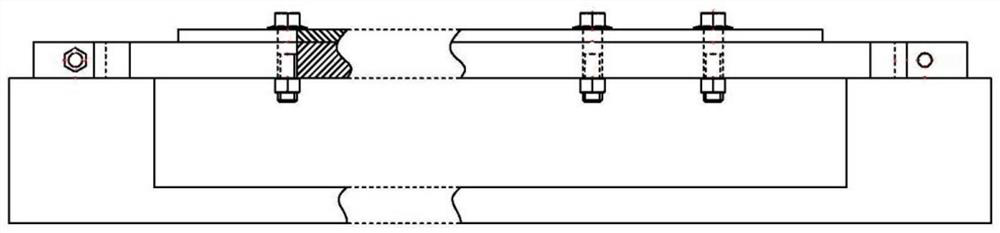

[0037] Such as Figure 1 to Figure 3 As shown, a test device for the correlation between tightening times and anti-corrosion ability of bolt fasteners includes a contact backing plate 3, a supporting backing plate 4, a clamp system 5, and an installation base 6; the contact backing plate 3 is provided with a plurality of perforations , used for testing multiple bolts at the same time; the supporting pad 4 is located under the contact pad 3 to provide support for the contact pad 3, and the length of the supporting pad 4 is longer than the length of the contact pad 3; the supporting pad Plate 4 also has a plurality of perforations, and the perforation position size on the supporting pad 4 is consistent with the perforation position size on the contact pad 3, and the supporting pad 4 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com