Offshore transformer winding unbalance rate high-precision measurement device and rapid test method

A technology of transformer windings and measuring devices, applied in transformer testing, electrical winding testing, etc., can solve problems such as excessive test remanence and influence of measurement results, achieve circuit stability, meet strict requirements, and avoid inaccurate data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

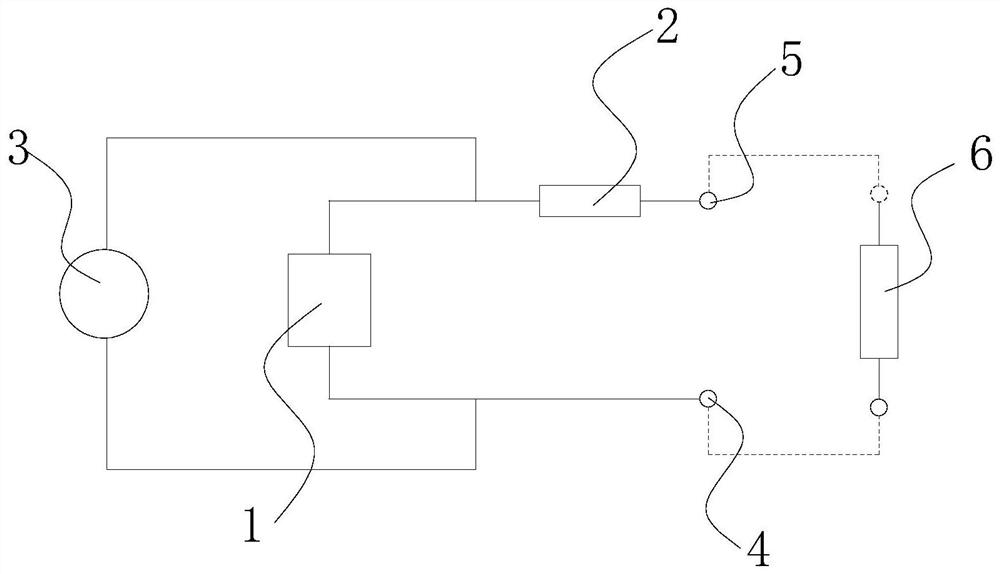

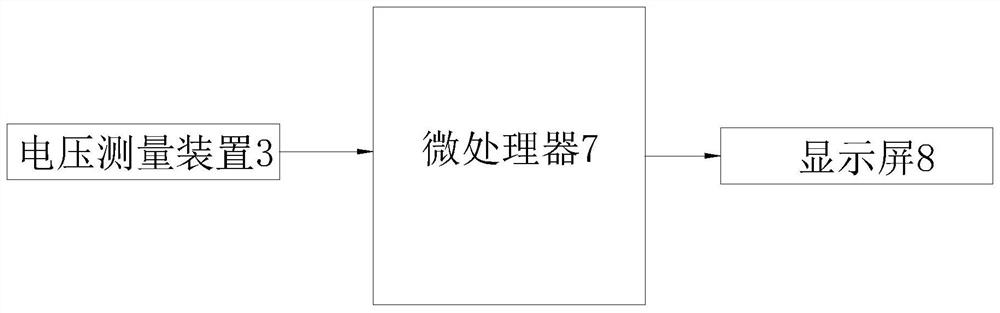

[0041] Such as figure 1 and figure 2 As shown, this embodiment provides a high-precision measuring device for the unbalance rate of offshore transformer windings, including a constant current source 1 , a microprocessor 7 , a display screen 8 connected to the microprocessor 7 , and a voltage measuring device 3 . The constant current source 1 is connected with a first lead-out 4 and a second lead-out 5, the first lead-out 4 and the second lead-out 5 are respectively used to connect the two ends of the transformer winding 6 to be tested to provide the transformer winding 6 to be tested. The current provided by the constant current source 1 is passed on, and an additional resistor 2 is connected in series between the first terminal 4 / second terminal 5 and the constant current source 1 . The two measuring ends of the voltage measuring device 3 are respectively connected to one end of the additional resistor 2 away from the transformer winding 6 to be tested and one end of the t...

Embodiment 2

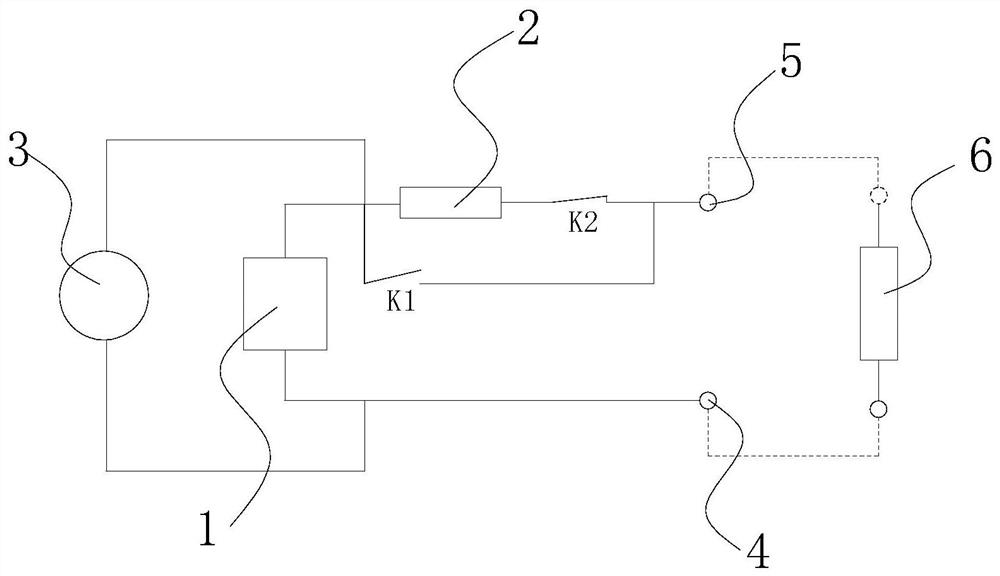

[0053] Such as image 3 and Figure 4 As shown, this embodiment is similar to Embodiment 1, the difference is that the microprocessor 7 of this embodiment is connected with a relay 9, the normally closed switch K2 of the relay 9 is connected in series with the additional resistor 2, and the normally open switch K1 is connected with the normally closed The switch K2 is connected in parallel with the additional resistor 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com