Pipeline connector based on optimized YOLOv3 algorithm and defect accurate identification method

A recognition method and connector technology, which are applied in neural learning methods, character and pattern recognition, instruments, etc., can solve the problems of low detection accuracy of small-diameter pipelines, lack of pipeline robots, and cumbersome detection work, so as to shorten the manual detection time and reduce Labor cost, the effect of fast recognition speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

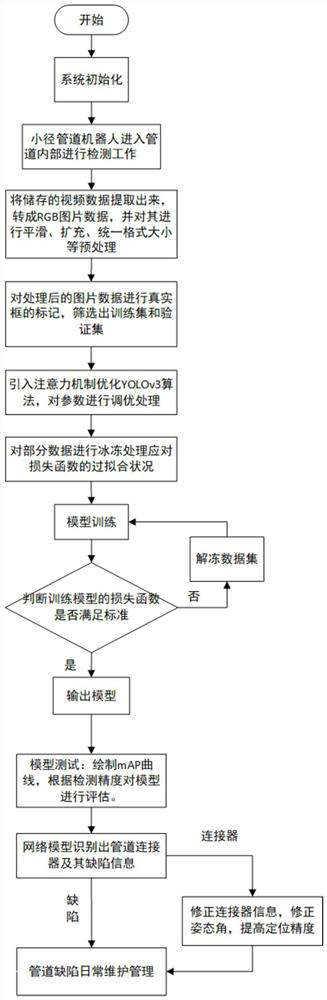

[0045] The method of the present invention is further described in detail in conjunction with the accompanying drawings. Based on the optimized YOLOv3 pipeline connector identification-assisted positioning and defect detection method, the specific steps include:

[0046] Step 1. Turn on the power module and initialize the small-diameter pipeline inspection robot;

[0047] Step 2. Let the small-diameter pipeline inspection robot enter the interior of the inspected pipeline for inspection, record the internal situation of the pipeline through the camera in front of the robot, and simultaneously process other information such as positioning information and inspection conditions through the data processing unit and store them in the data storage unit middle;

[0048] Step 3. Extract the stored video data, convert it into RGB image data t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com