Soy sauce production integrated device

A soy sauce and box technology, applied in biochemical cleaning devices, cooling fluid circulation devices, enzymology/microbiology devices, etc., can solve the problems of sundries mixed in, increase the workload of work, etc., achieve temperature balance and save manual handling , Improve fermentation efficiency and fermentation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

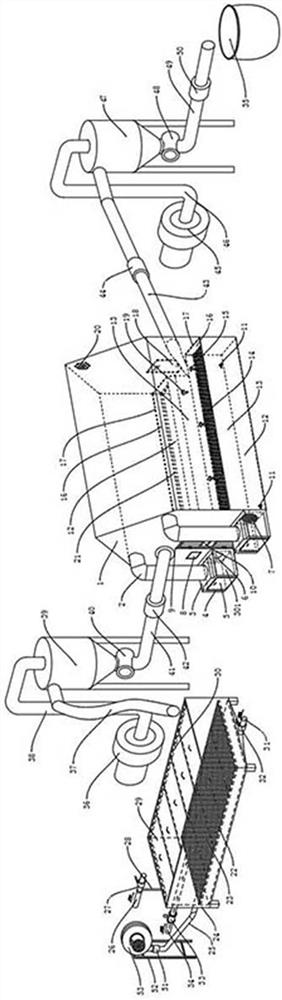

[0040] Such as Figure 1-8 As shown, an integrated device for soy sauce production includes a cooking section, a first negative pressure feeding section, a fermentation section, a second negative pressure feeding section, and a soy sauce brewing tank; the cooking section and the fermentation section pass through the first negative pressure The feeding part is connected; the fermenting part is connected with the soy sauce brewing tank through the second negative pressure feeding part.

[0041] The specific working method:

[0042] Put the soybeans into the steaming section for cleaning. After cleaning, soak the soybeans in the steaming section for 2 to 4 hours; after soaking, the steaming section steams the soybeans in it. The feeding part is transported to the fermentation part, and the soybeans are sealed and fermented in the fermentation part. After the fermentation is completed, the soybean fermentation products in the fermentation part are transported to the soy sauce bre...

Embodiment 2

[0045] Compared with Example 1, the difference lies in that a structural form of the fermenting part is provided.

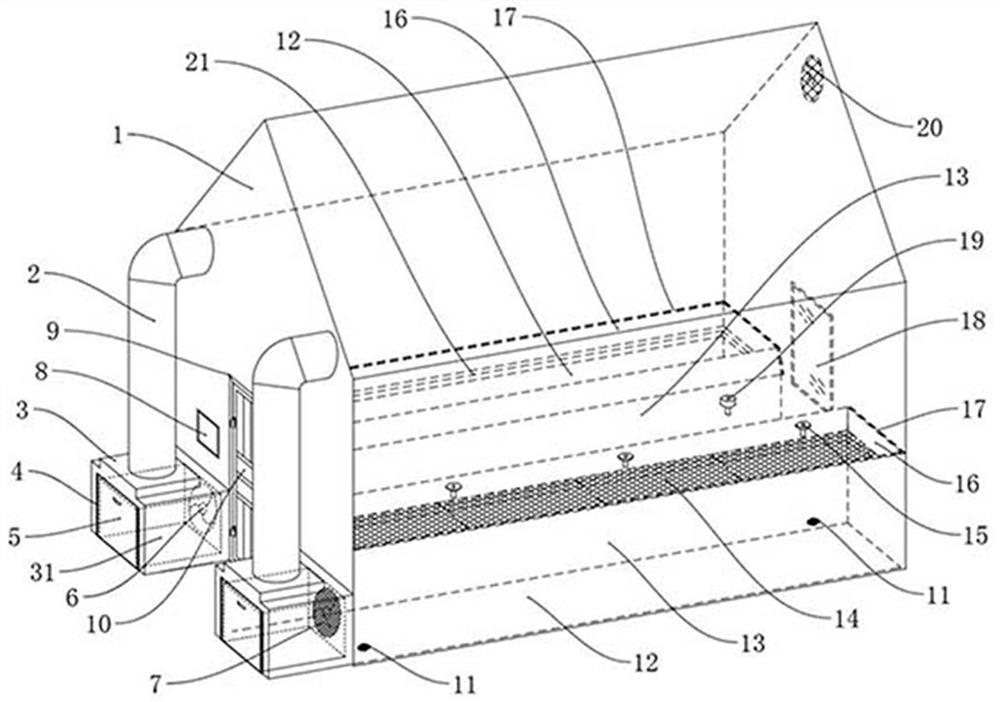

[0046] Such as Figure 2-6 As shown, the fermentation section includes a circulation ventilation section, a fermentation room 1, a door 9, a fermentation door 10, a fermentation tank 12, a wall 13, a support net 14 and a support frame 21; the top of the fermentation room 1 is in a triangular structure, A doorway 9 is provided on its side surface, and a fermentation door 10 is installed on the doorway 9, and at least one fermentation tank 12 is surrounded by a wall 13 and the wall surface of the fermentation room 1 in the fermentation room 1; At least one circulation and ventilation part is provided, wherein one circulation and ventilation part is correspondingly connected with a fermenter 12, and the other end of the circulation and ventilation part is connected with the top of the fermentation room 1; the support frame 21 is close to the The top of the fermenta...

Embodiment 3

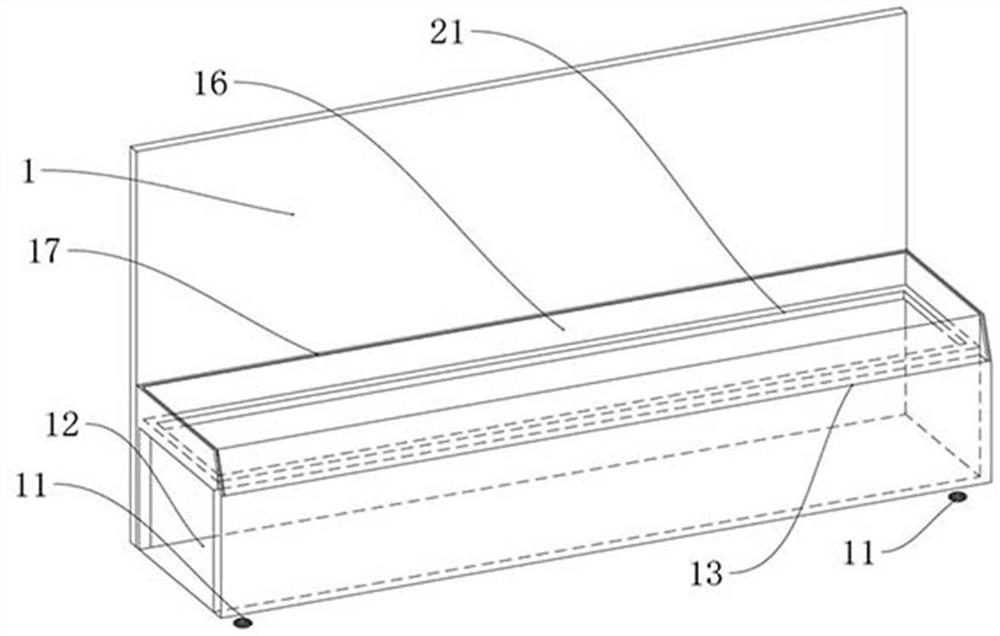

[0058] Compared with Embodiment 2, the difference is that: in order to facilitate the reasonable collection and discharge of the water condensed on the wall in the fermentation room, and to prevent the water from slipping off the support net, a support wall 16 and a water drainage ditch are added. 17.

[0059] The supporting wall surface 16 is attached to the wall surface of the fermentation room 1 with a bonding height of 1.2m-1.8m, and a water drainage ditch 17 is opened on the top surface of the supporting wall surface 16 at the bonding place.

[0060] Commonly used bonding heights are 1.2m, 1.3m, 1.4m, 1.5m, 1.6m, 1.7m or 1.8m. Thereby, the height of the fermentation tank 12 can be higher. Thereby it is prevented that the water droplets condensed on the inner wall surface of the fermentation room on the top of the fermentation tank fall into the supporting net, thereby preventing the water droplets from dripping on the fermented product.

[0061] The accumulated water dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com