Variable-diameter shell inner welding seam shape-follow-up grinding and polishing machining robot

A technology of robots and processing mechanisms, which is applied to machine tools, metal processing equipment, grinding/polishing equipment, etc. suitable for grinding the edge of workpieces, and can solve problems such as inability to follow the shape of the pipeline for grinding and polishing, and inability to adapt to the tapered pipeline. Achieving adaptability and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail in conjunction with the drawings and technical solutions.

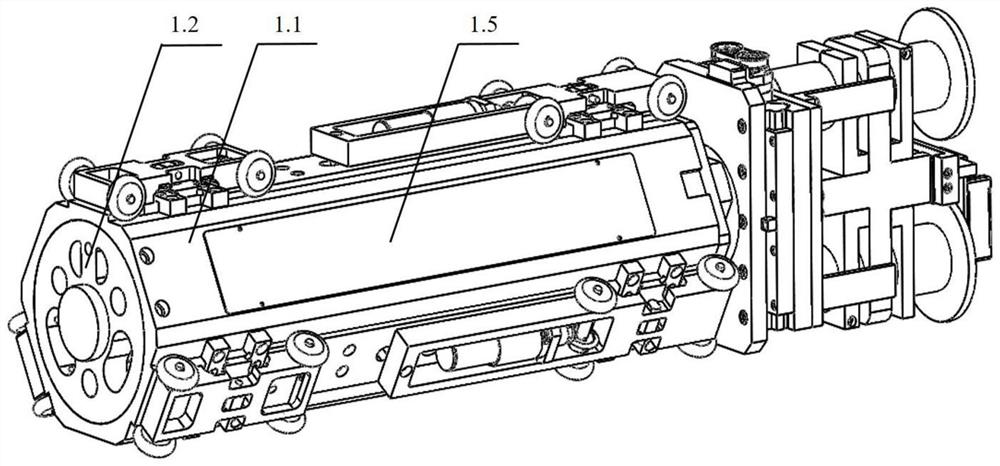

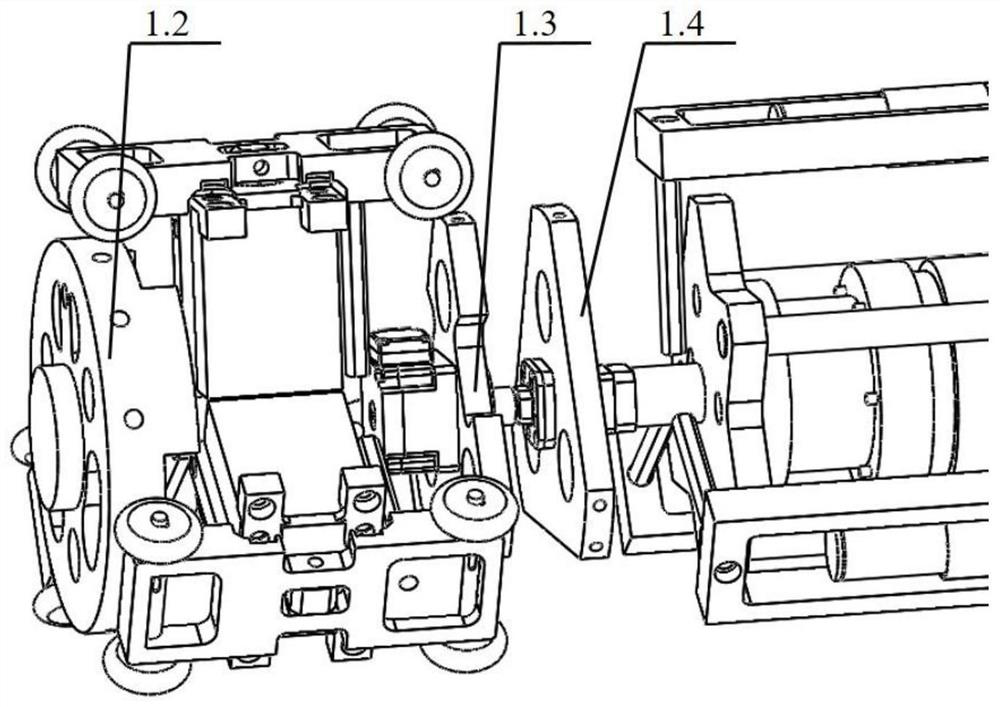

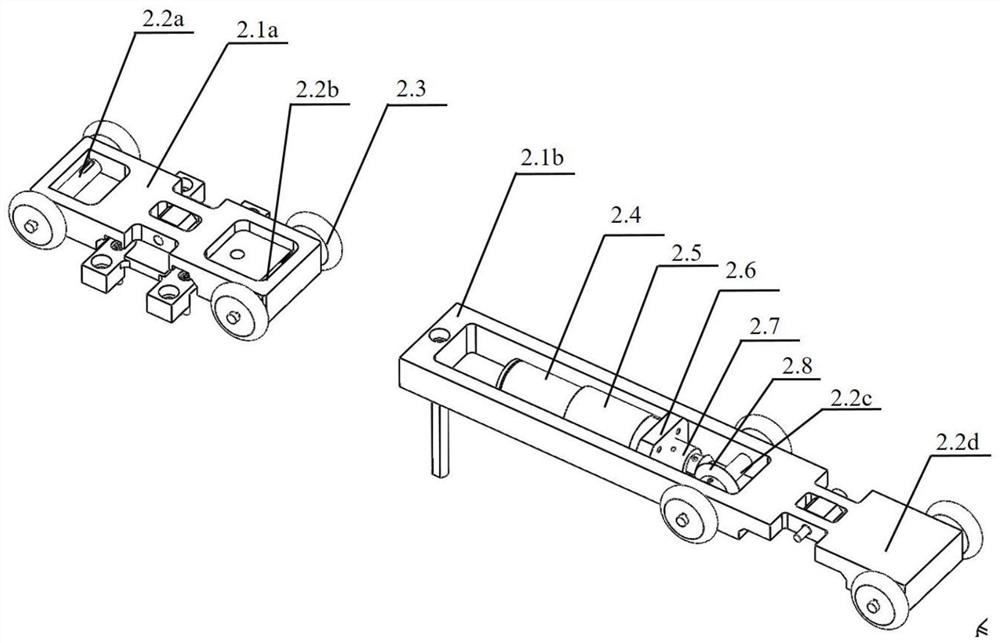

[0027] A robot for conformal grinding and polishing of weld seams in a variable-diameter shell mainly includes a robot shell 1 , a double-row circumferential servo movement mechanism 2 , a pneumatic variable-diameter mechanism 3 , and a processing mechanism 4 . The robot shell 1 is used as a structural part of the robot for installation of motors, cylinders and the like. The double-row circumferential servo motion mechanism 2 can adapt itself to the straight / conical shell to realize the walking of the robot in the straight / conical shell; the pneumatic variable diameter mechanism 3 can adapt to the variable-diameter shell to realize the flexibility in the shell. The movement and processing state are maintained with high rigidity; the processing mechanism 4 is used to complete the conformal grinding and polishing processing of the welding seam i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com