Coal sample supply and transportation mechanism based on intelligent sampling and weighing

A coal sample and weighing technology, applied in conveyors, transportation and packaging, conveyor objects, etc., can solve the problems of reducing weighing accuracy, reducing production efficiency, inaccurate coal sampling records, etc., and improving drying efficiency. effect, the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

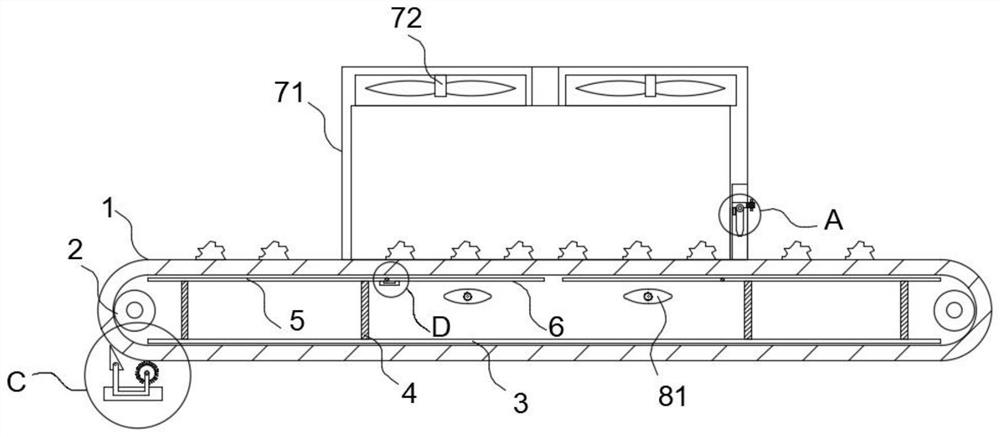

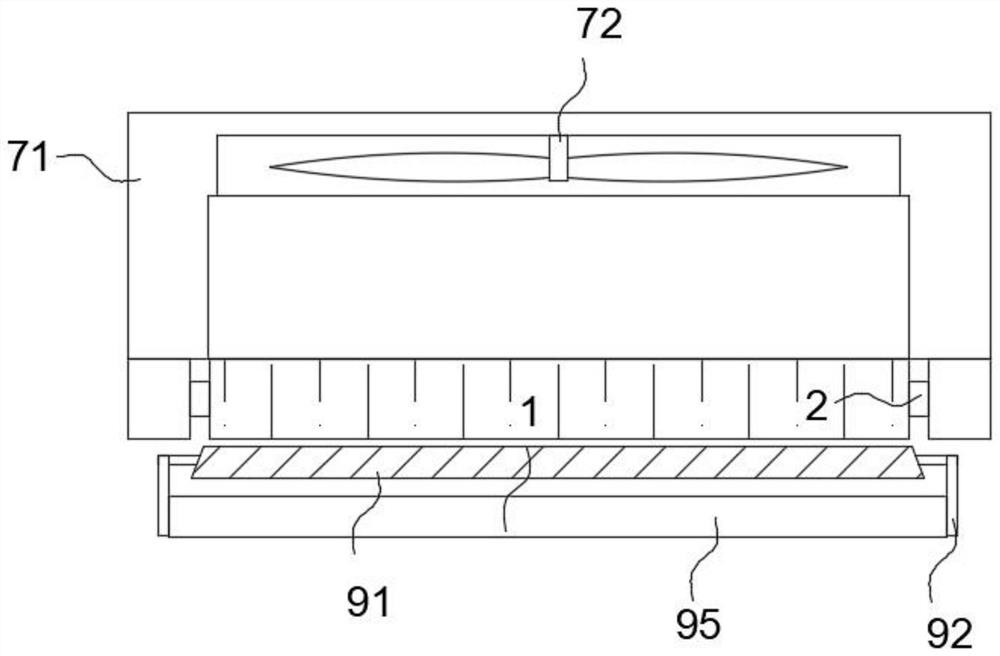

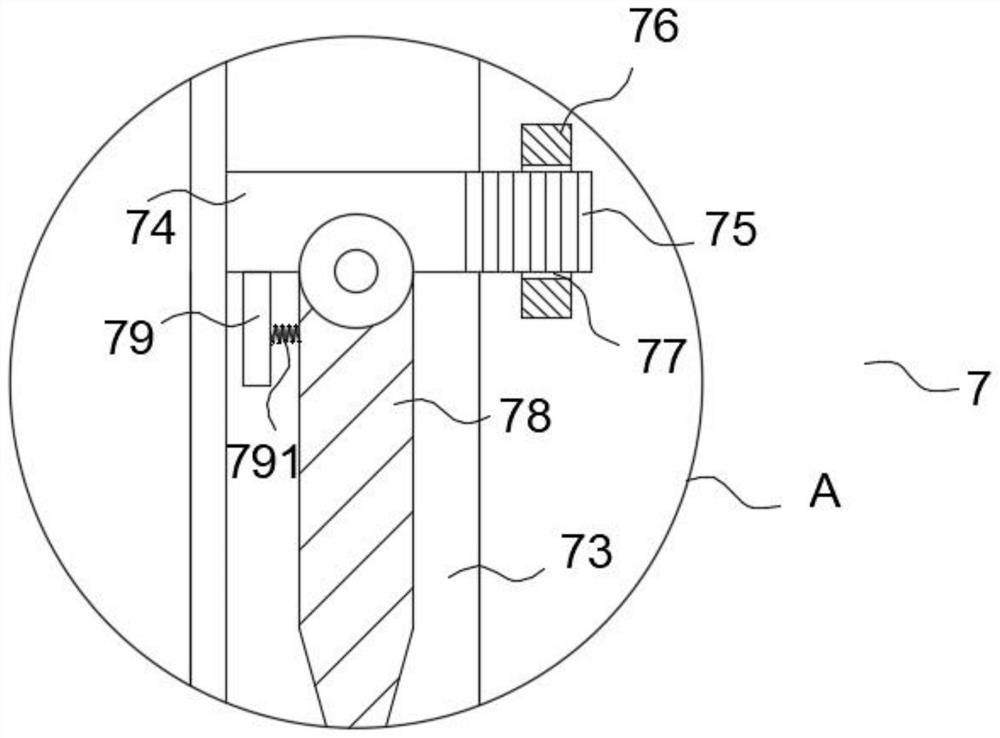

[0029] like Figure 1-8 As shown, the coal sample supply and transportation mechanism based on intelligent sampling and weighing proposed by the present invention includes a conveyor belt 1 and a drive roller 2, the inside of the conveyor belt 1 is provided with a bottom plate 3, and the outer surface of the upper end of the bottom plate 3 is centered at the center. A number of support rods 4 are fixedly connected symmetrically at the midpoint, and a top plate 5 is fixedly connected to the upper ends of the several support rods 4, and a vibrating plate 6 is hinged on one side of the outer surface of the top plate 5, which is used to lift the conveyor belt 1 and lift it up. To the effect of vibration, the outer surface of the upper end of the conveyor belt 1 is provided with a drying mechanism 7 near the middle position, and the inside of the conveyor belt 1 is provided with a vibration mechanism 8; the drying mechanism 7 includes a drying box 71, a heating fan 72. Feed port 73...

Embodiment 2

[0033] like Figure 1-7 As shown, the outer surface of the lower end of the conveyor belt 1 is provided with a cleaning mechanism 9 near the other side;

[0034] The cleaning mechanism 9 includes a cleaning scraper 91, a connecting rod 92, a cleaning roller brush 93, a second rotating motor 94, and a storage box 95; the outer surface of the front end of the cleaning scraper 91 is fixedly connected with a connecting rod 92 near the middle position, The connecting rod 92 has a U-shaped structure, and a cleaning roller brush 93 is movably connected to one side of the rear end of the connecting rod 92 of the U-shaped structure, and a second rotating motor is fixedly connected to the outer surface of the rear end of the cleaning roller brush 93. 94, used to drive the rotation of the cleaning roller brush 93, so that the cleaning roller brush 93 and the conveyor belt 1 rotate in the opposite direction, and the outer surface of the lower end of the cleaning scraper 91 and the cleanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com