Flexible ultralow-frequency vibration isolator

A vibration isolator, ultra-low frequency technology, applied in low internal friction springs, springs/shock absorbers, springs, etc., can solve the problems of limited bandgap depth, reduced vibration isolation effect, and reduced resonance frequency, so as to widen the vibration isolation. Bandwidth, reduce resonance frequency, reduce the effect of installation error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

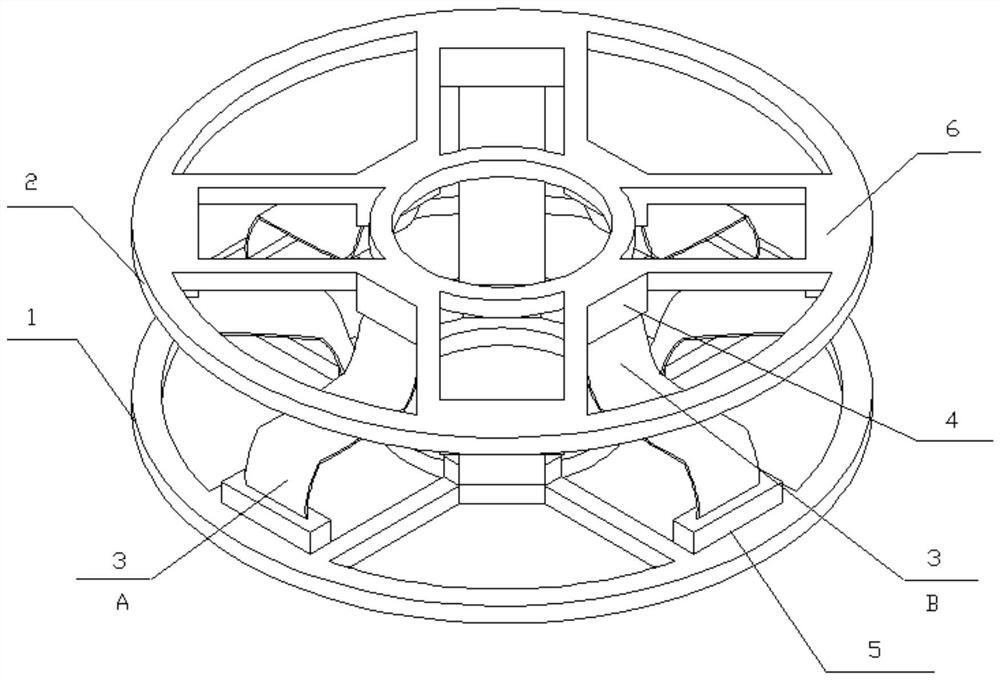

[0022] figure 1 It reflects the structure of a group of vibration isolation units of the flexible ultra-low frequency vibration isolator of the present invention. It can be seen from the figure that the vibration isolation unit has a lower support seat 1, an upper support seat 2 and a spring piece 3, wherein the spring piece 3 is located on the lower support Between the seat 1 and the upper support seat 2, the lower connection end 31 of the spring leaf 3 is located in the lower support seat 1, and the upper connection end 32 of the spring leaf 3 is located in the upper support seat 2.

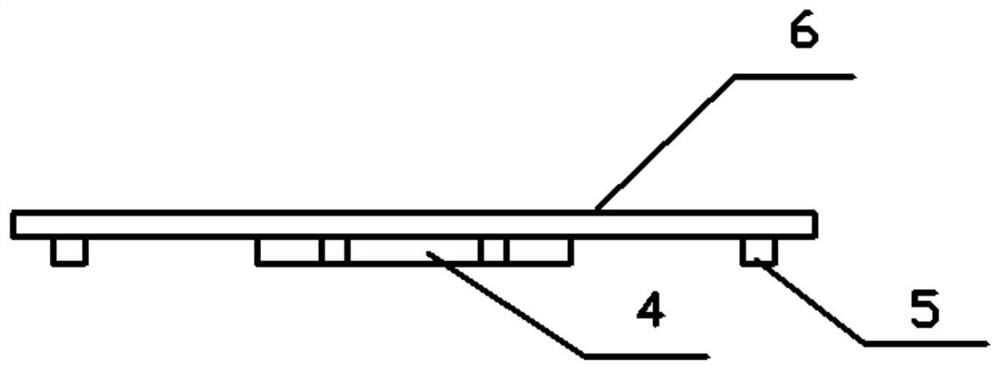

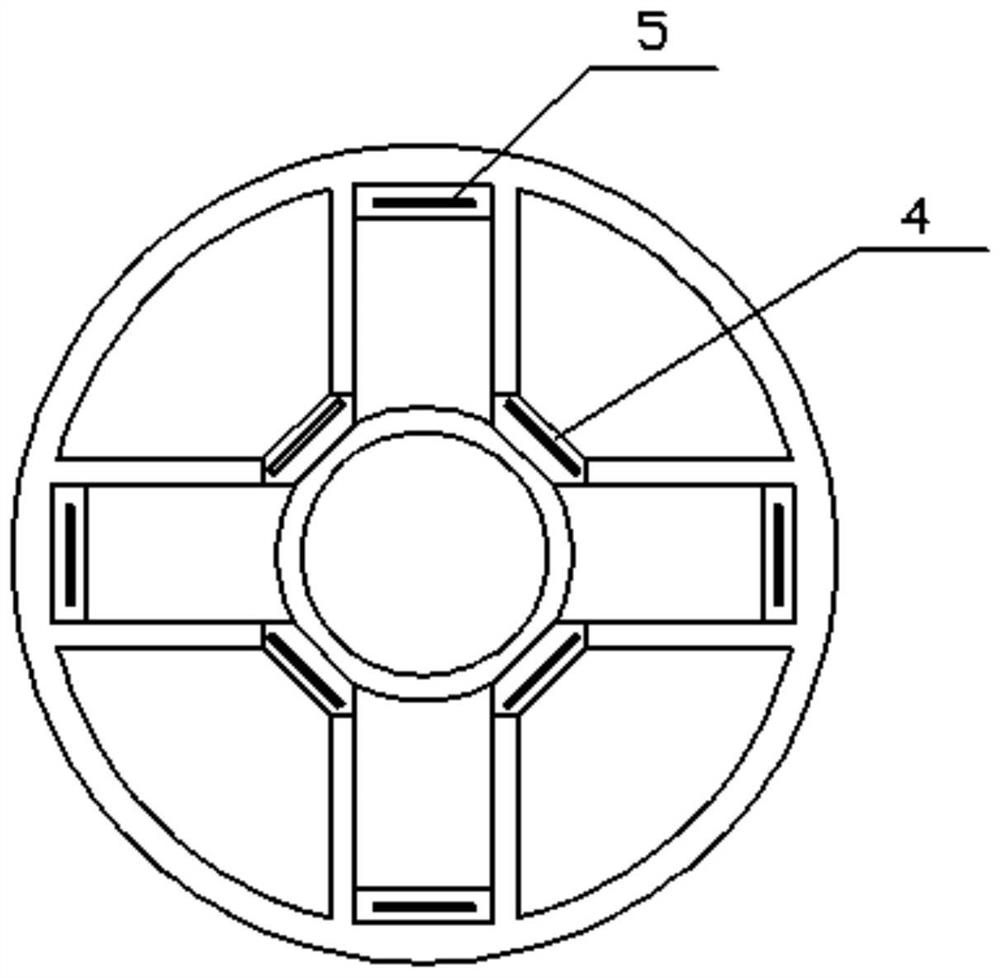

[0023] Figure 2-Figure 4 Reflecting the structure of the upper support base 2, the top surface 6 of the upper support base has a structure capable of superimposing another vibration isolation unit, the lower support base 1 and the upper support base 2 have the same structure, combined figure 1 It can be seen that both the lower support seat 1 and the upper support seat 2 have an inner ring sp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap