Automatic gear shifting actuator for new energy automobile

A new energy vehicle, automatic gear shifting technology, applied in transmission elements, vehicle parts, vehicle gearboxes, etc., can solve the problems affecting the safety performance of automatic gear shifting, gears are easy to wear, etc., to achieve low wear, smooth gas flow, Fast reset effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

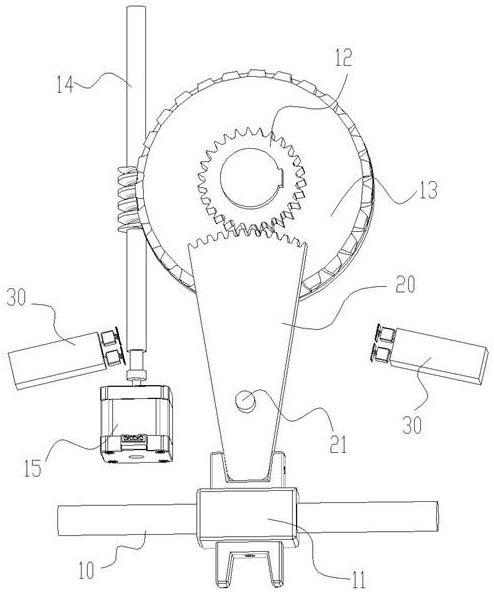

[0048] Figure 1~Figure 4 Schematically shows an automatic shift actuator for a new energy vehicle according to an embodiment of the present invention, including a shift lever 10, the shift lever 10 is connected to a sector gear 20, and the sector gear 20 is far away from the shift lever One end of 10 meshes with the main gear 12, and the reciprocating rotation of the main gear 12 drives the sector gear 20 to swing back and forth within a certain range, thereby realizing the movement of the shift lever 10.

[0049] like figure 1 As shown, the shift lever 10 is arranged horizontally, the middle part is covered with a connecting piece 11 , and the end of the sector gear 20 away from the main gear 12 is fixedly connected with the connecting piece 11 . The outer side of the main gear 12 is provided with a coaxial worm wheel 13 , the worm wheel 13 meshes with the worm 14 , and one end of the worm 14 is connected with the output end of the drive motor 15 . The worm 14 drives the w...

Embodiment 2

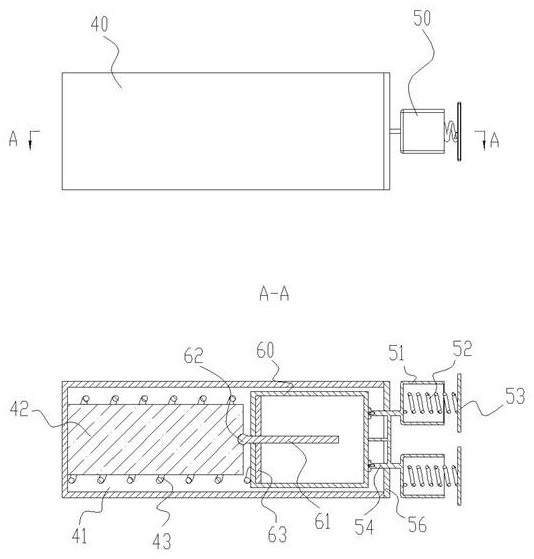

[0062] Figure 5~Figure 8 Schematically shows an automatic shift actuator for new energy vehicles according to another embodiment of the present invention, the difference from Example 1 is:

[0063] One end of the third base body 60 away from the spherical connection portion 62 is configured with a first rebound support member 64 and a second rebound support member 65, the first rebound support member 64 is located inside the third base body 60, and is connected to the swing rod 61 The end of the third base body 60 is matched with the second resilient support member 65 outside the third base body 60 and fits with the end of the third base body 60 .

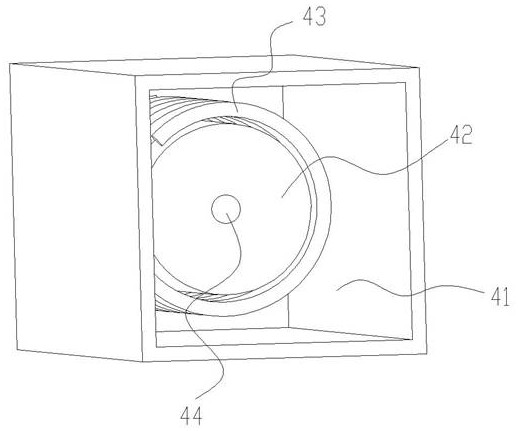

[0064] The first resilient support member 64 has the same structure as the second resilient support member 65, including a support circular plate 66 and a plurality of support feet 67, and the plurality of support feet 67 are evenly distributed on the edge of the support circular plate 66 in a radial shape, like Image 6 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com