Multifunctional test equipment with thermal stress test and test method of multifunctional test equipment

A multi-functional testing and thermal stress technology, which is applied in the direction of measuring electric power, environmental/reliability testing, and components of electrical measuring instruments, etc., can solve the problems of affecting judgment accuracy, high labor intensity, and low degree of automation, so as to improve Test efficiency, shorten test time, and ensure the effect of test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

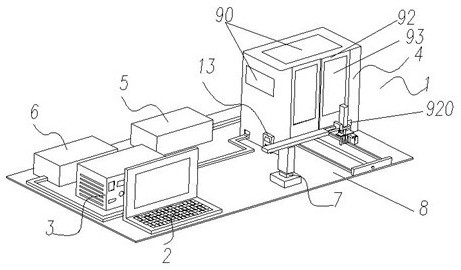

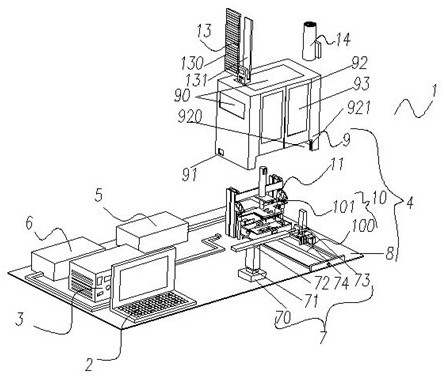

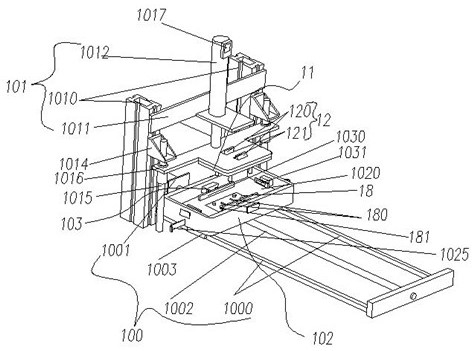

[0036] Examples, see attached Figure 1~Figure 5 , a kind of multifunctional testing equipment 1 with thermal stress test comprises upper computer PC2, electrical controller 3, test cabinet 4, load 5 and data acquisition device 6, described upper computer PC2, electrical controller 3, test cabinet 4, A cable is provided between the load 5 and the data acquisition device 6 to form an electrical connection, one end of the PC2 is electrically connected to the electrical controller 3, and the electrical controller 3 is connected to the test cabinet 4, The test cabinet 4 is connected with the load 5, the load 5 is connected with the data acquisition device 6, the data acquisition device 6 is connected with the other end of the upper computer PC2, and the multifunctional test equipment 1 is also A handling manipulator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com