Chip frame fixing support of semiconductor chip wire bonding equipment

A technology for fixing brackets and semiconductors, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc. It can solve the problems of frame shaking, offset, unavoidable chip frame warping or vibration, and high defect rate, so as to reduce the number of products The scrap rate and the effect of avoiding bad solder joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

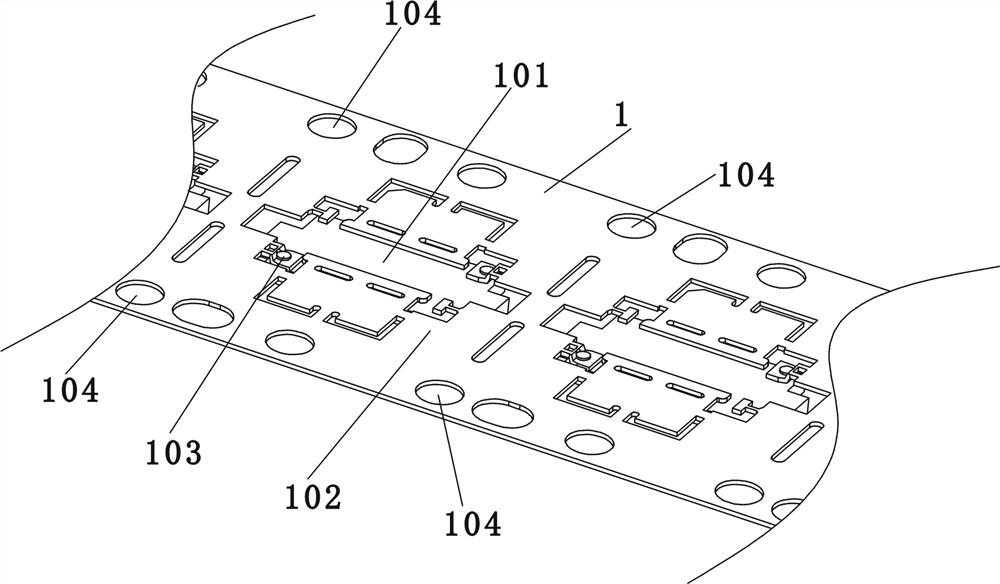

[0029] figure 1 It is a schematic diagram of the structure of the chip frame, which is a chip frame 1 of the TO-270 package type. It is composed of a small bottom plate 101 and a large upper plate 102. The connecting column 103 at the end is connected with the connecting piece formed by the downward bending of the upper plate 102 . There are two steps formed by a bottom plate 101 and an upper flat plate 102 on its side. After wire bonding, the semiconductor chip is fixed on the base plate 101 and connected with wires. When ultrasonic bonding wires are used, in order to avoid defective solder joints caused by warping of the chip frame caused by ultrasonic vibration, it is necessary to fix each part of the chip frame 1 respectively.

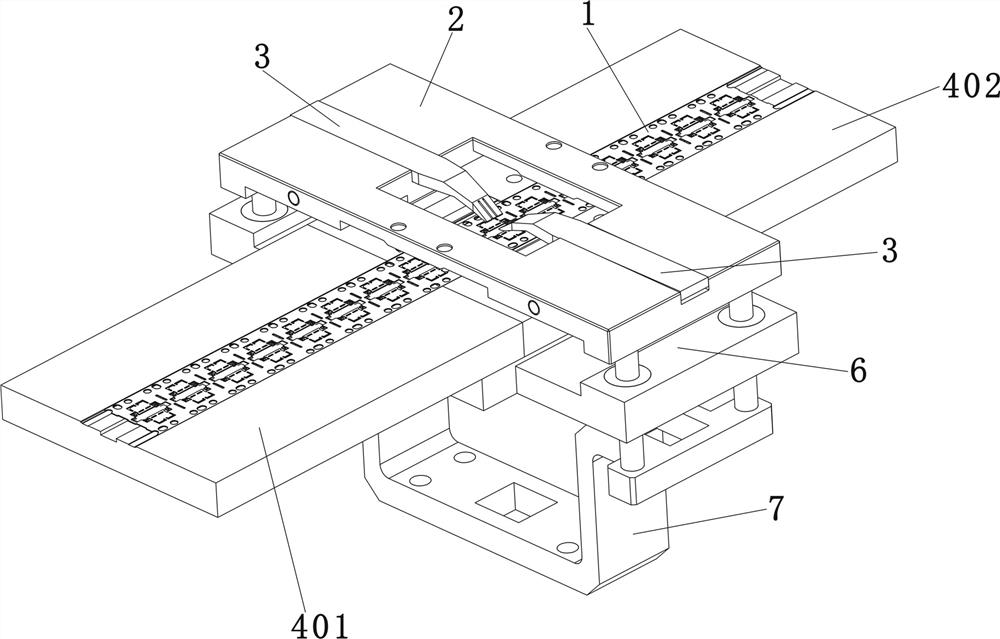

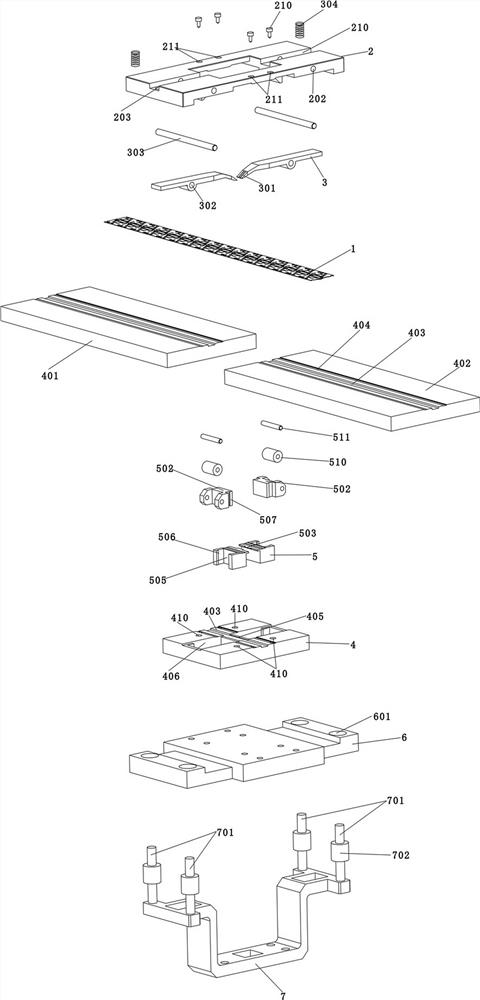

[0030] Figure 2-Figure 8 Showing an embodiment of the present invention, the chip frame fixing bracket includes a platen pressing mechanism, a central track module, a chip frame positioning mechanism, a retractable insertion piece, and a drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com