Microneedle pouring system and microneedle preparation method

A pouring system and microneedle technology, applied in the field of microneedles, can solve problems such as difficult to ensure consistency, unfavorable for large-scale mass production, and long time, so as to ensure replication accuracy and consistency, high pouring efficiency, and less liquid usage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

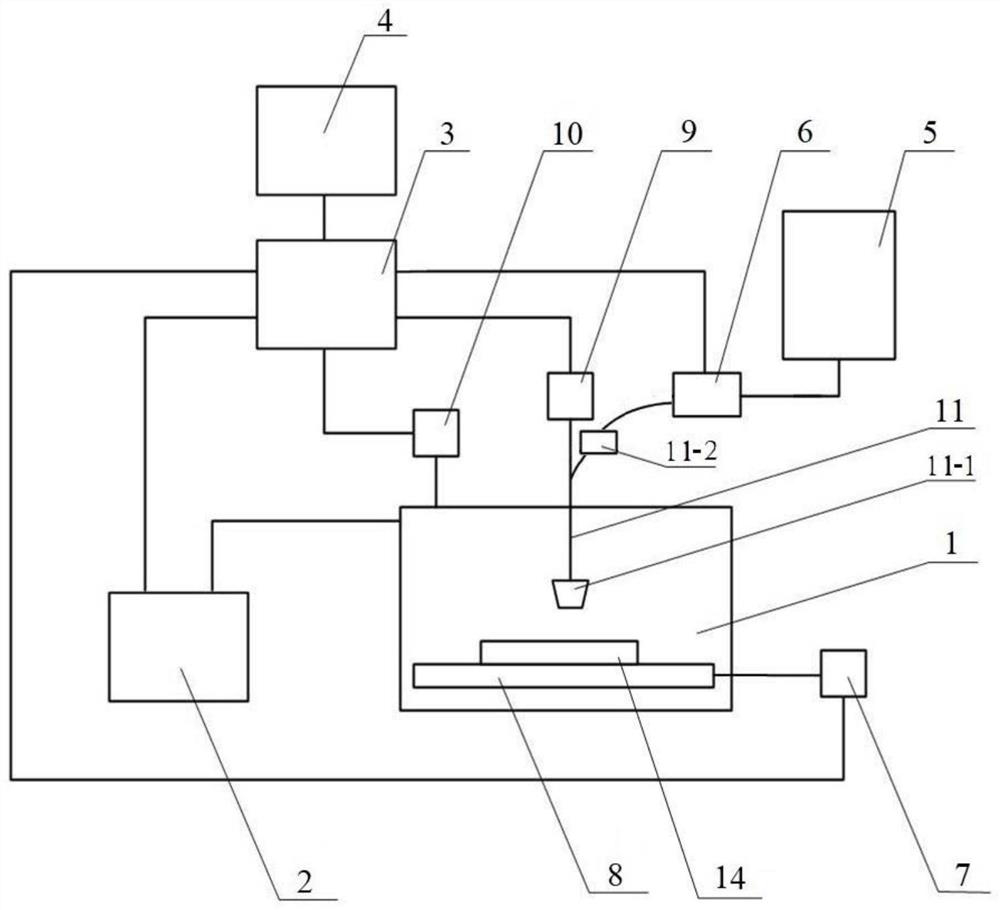

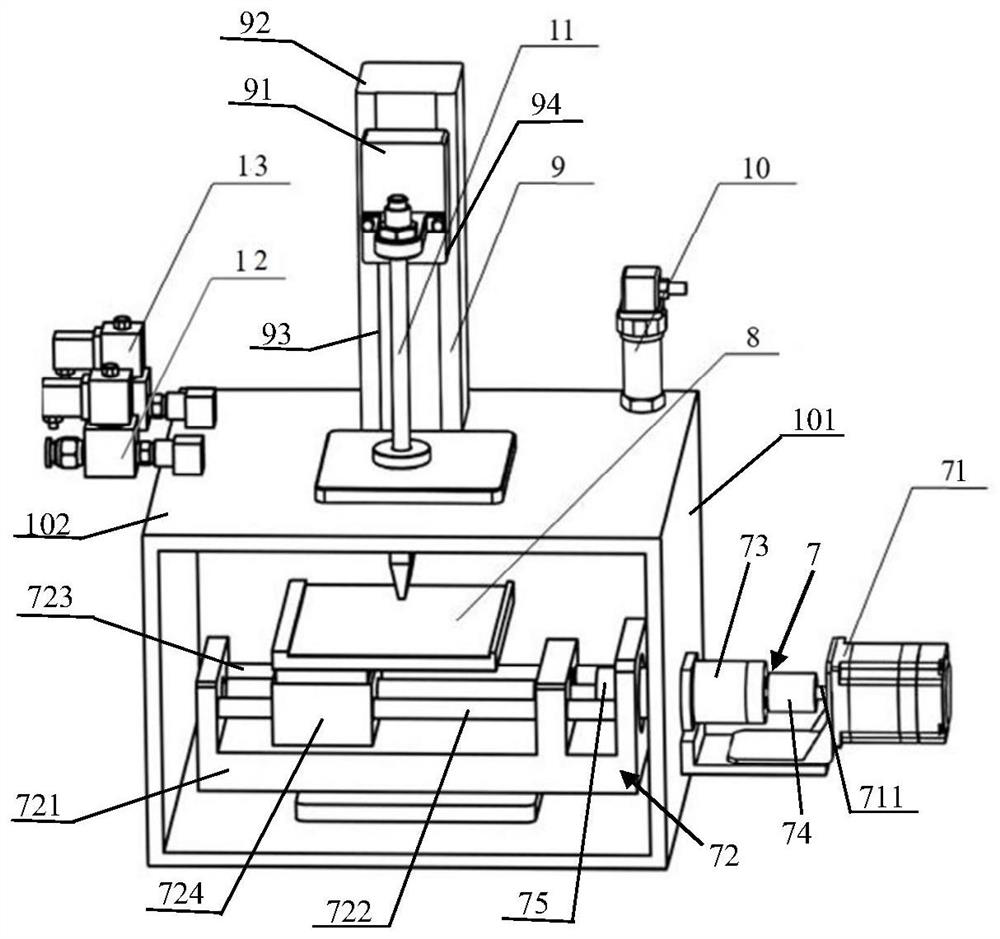

[0056] This embodiment provides a microneedle pouring system, including: a vacuum chamber 1, a vacuum pump 2, a controller 3, a display system 4, a mixing tank 5, a filling pump 6, a first moving assembly 7, a moving platform 8, The second moving assembly 9 , a vacuum gauge 10 , a filling needle assembly 11 , a vacuum valve 12 , and a vacuum release valve 13 .

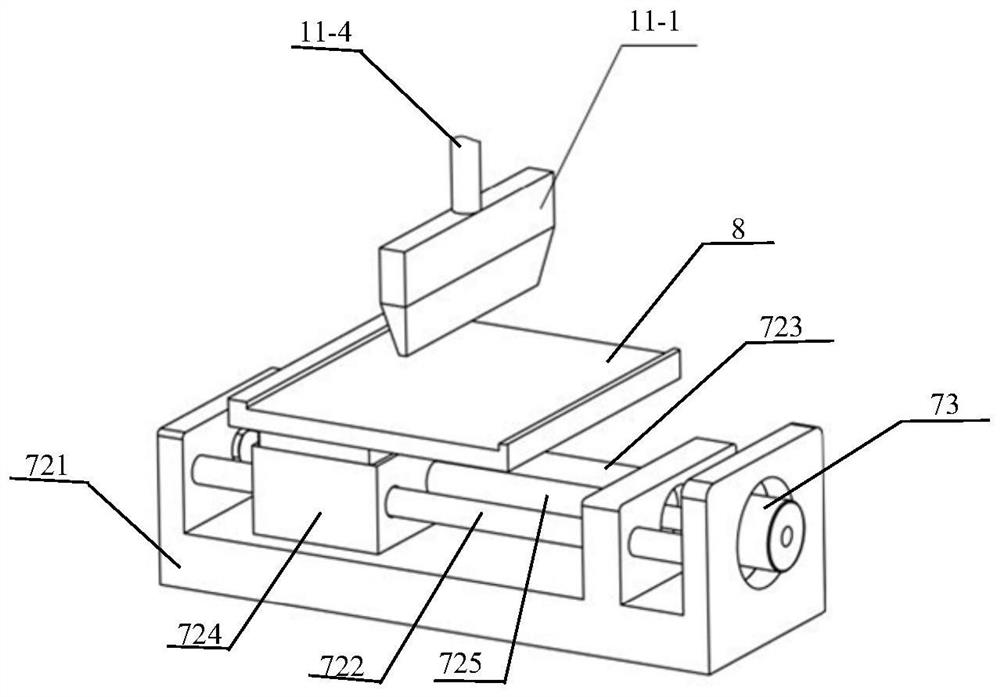

[0057] Such as figure 1 As shown, the vacuum chamber 1 is used to provide a closed environment, so as to realize the preparation of microneedles under vacuum conditions. The motion platform 8 is arranged in the vacuum chamber 1 . In this embodiment, the moving platform 8 moves in one direction and is used to support the microneedle casting mold 14 . Such as Figure 8 As shown, the microneedle cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com