High-precision numerical control horizontal turning machine boring machine with double-mountain-shape guide rail

A horizontal lathe, high-precision technology, applied in the field of machine tools, to achieve the effects of convenient maintenance, improved processing efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

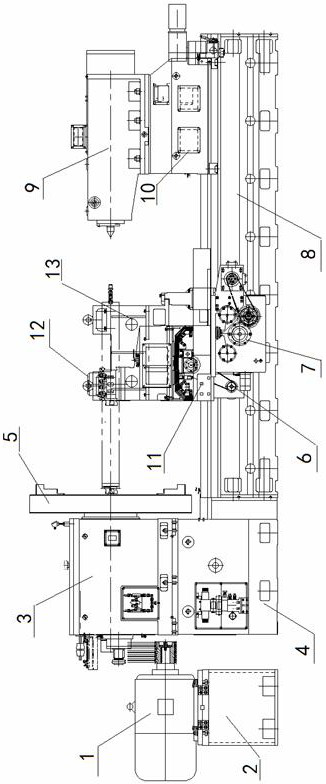

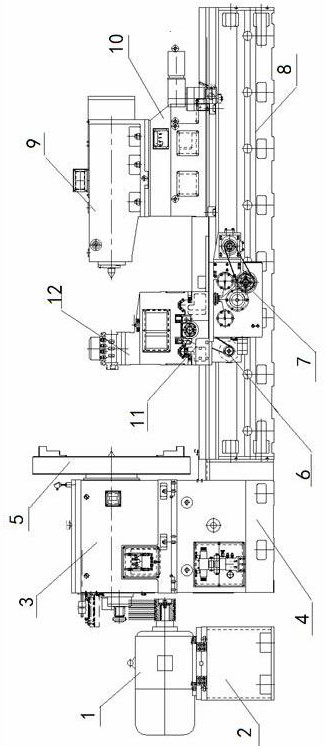

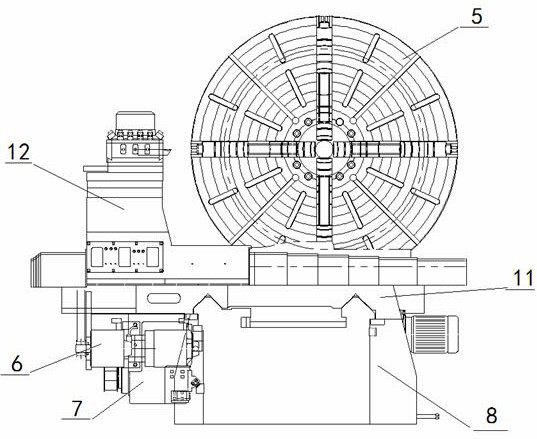

[0016] Such as Figure 1-6 As shown, a CNC horizontal lathe boring machine with high-precision double-mountain guide rails includes a CNC horizontal lathe, a large tool rest 11, an upper tool rest 12 and a boring device 13, and the main motor 1 of the CNC horizontal lathe is installed on the base of the main motor 2, the headstock 3 is installed on the headstock base 4, the headstock base 4 is connected with the bed 8, the main motor base 2, the headstock base 4 and the bed 8 are connected as a whole through the ground pads, and the main motor 1 The faceplate 5 is driven to rotate through the timing belt and the gear in the headstock 3, the upper body of the tailstock 9 is installed on the lower body of the tailstock 10, and the lower body of the tailstock meshes with the rack on the bed 8 through the feed motor Movement, after the tailstock lower body 9 is in place, the gear plate and the tooth grooves on the bed body are engaged to ensure that the tailstock does not move dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com