Processing method of ceramic dielectric window for plasma etching machine

A ceramic medium and processing method technology, applied in the field of ceramic processing, can solve the problems of low production efficiency and high production cost, and achieve the effects of improving processing efficiency, reducing production cost, and good guidance and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

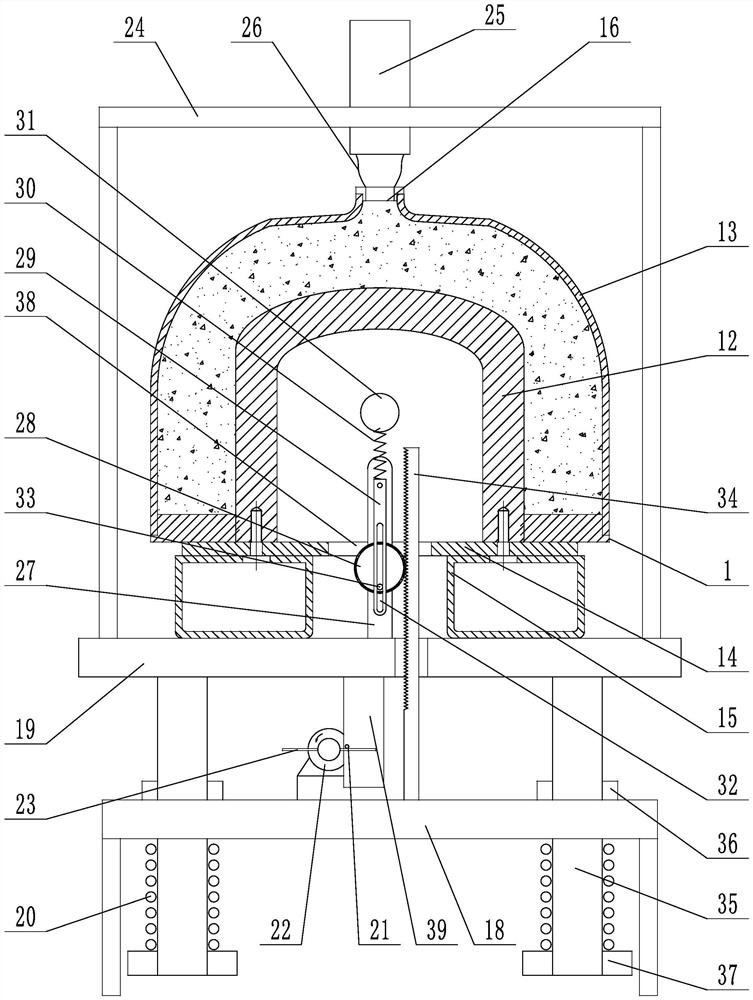

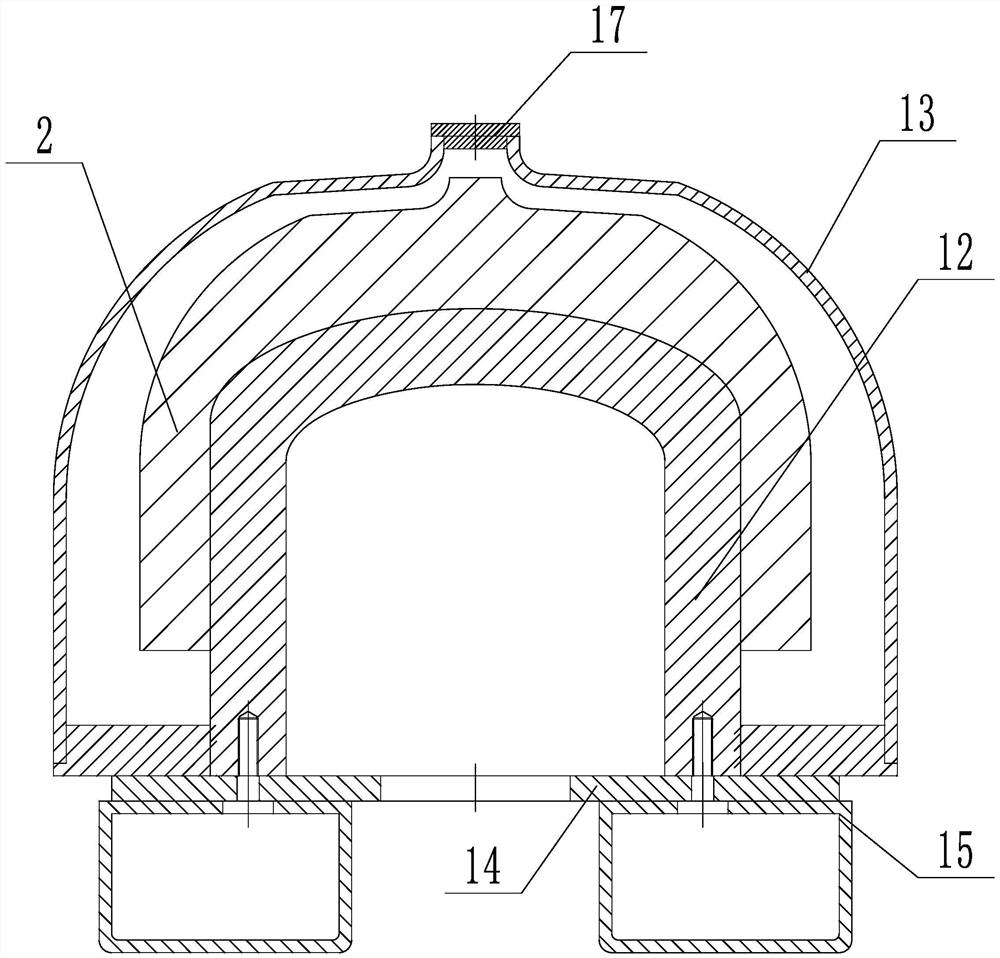

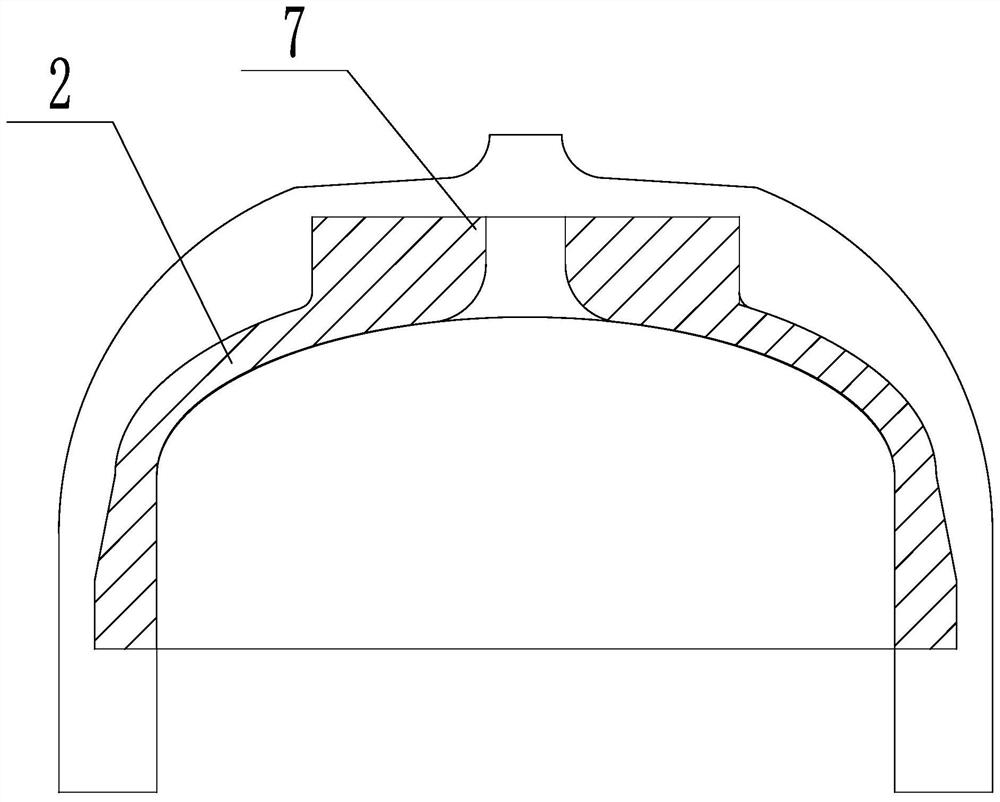

[0026] Embodiment: A kind of processing method of ceramic dielectric window for plasma etching machine (see attached figure 1 to attach Figure 5 ), comprising the following steps: a. putting ceramic powder into the cold iso-finishing mold 1; The static pressure cylinder pressurizes the cold isostatic pressing forming mold and maintains the pressure; c, takes out the cold isostatic pressing forming mold, and demolds and takes out the ceramic dielectric window green body 2; d, grinds the outer contour of the ceramic dielectric window green body grinding process; e, put the ceramic dielectric window green body that has completed the outer contour grinding into the sintering furnace 3 for sintering, set a support platform 4 in the sintering furnace, and set a number of supporting convex rings 5 on the support platform, and open the ceramic dielectric window green body Support upward on the supporting convex ring, and put sintering sand into the sintering furnace; f, take out t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap