Steel pipe inner surface magnetic powder inspection deep hole fluorescence imaging device and using method thereof

A magnetic particle flaw detection and fluorescence imaging technology, applied in the direction of measuring device, fluorescence/phosphorescence, material magnetic variables, etc., can solve the problems of occupying 2 optical paths of steel pipes, unable to cover a large depth range of pipe ends, unable to irradiate ultraviolet light, etc. good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

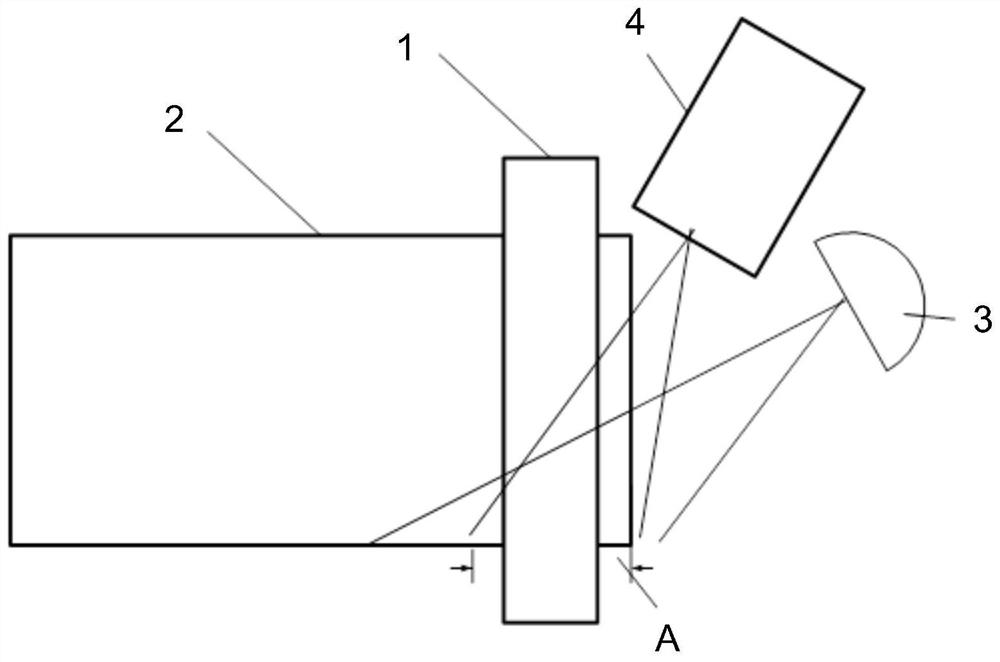

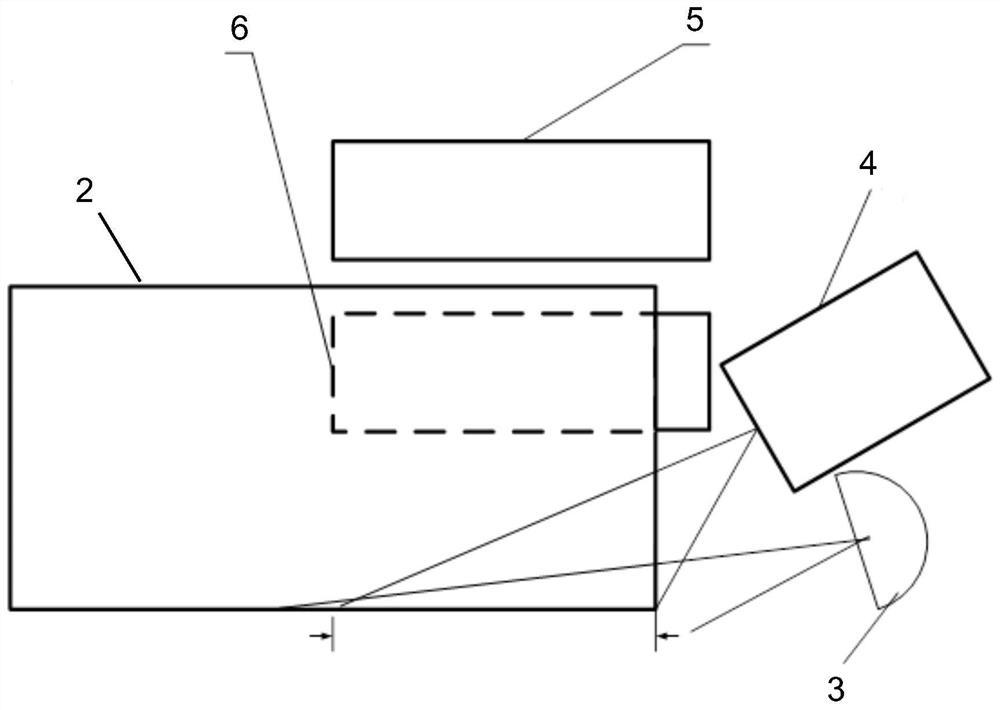

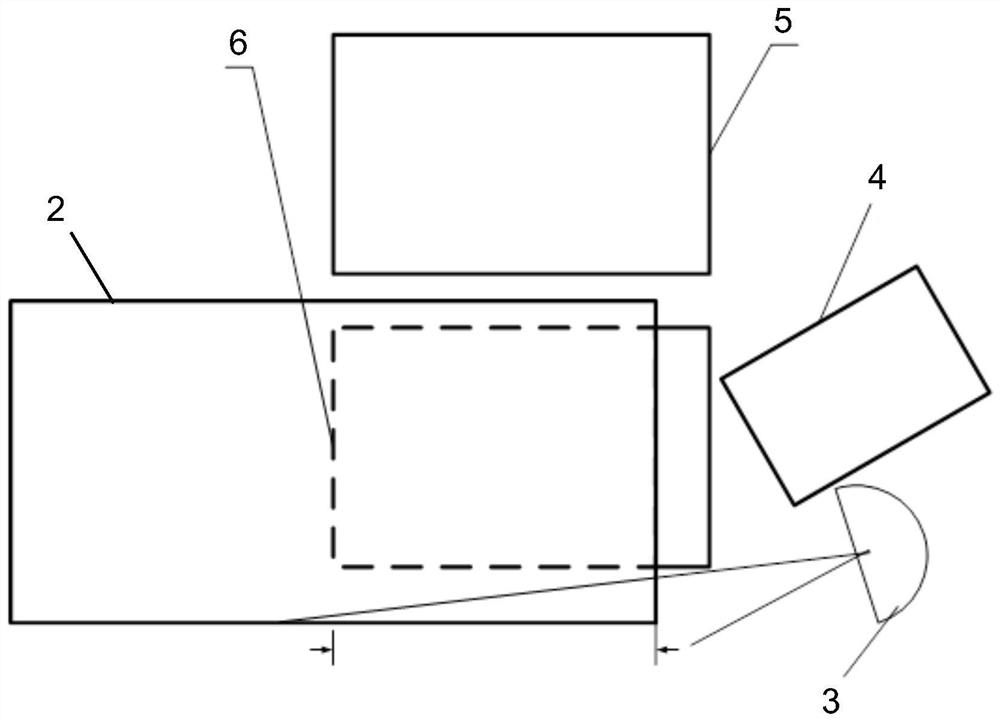

[0041] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0042] Please combine Figure 5 to Figure 6 As shown, a deep hole fluorescent imaging device for magnetic particle flaw detection of steel pipe inner surface provided by the present invention includes a yoke base 11 installed on one side of the steel pipe 10 port, a yoke coil 12 is installed on the yoke base 11, and the magnetic The side of the yoke coil 12 facing the steel pipe 10 port is connected with a mandrel 13 .

[0043] Mandrel 13 comprises the detection section (such as Figure 5 The dotted line part located inside the steel pipe 10), and the reserved section located outside the port of the steel pipe 10 (such as Figure 5 The solid line part located outside the steel pipe 10), the reserved section is connected to the side of the yoke coil 12, and an ultraviolet reflector 14 is equipped next to the detection section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com