QPIC-based HMI simulation and automatic verification method realized

A technology of automated verification and automated testing, applied in design optimization/simulation, generation of response errors, inter-program communication, etc., can solve problems such as picture interference, inability to be portable, and low efficiency, saving project costs and facilitating analysis and the effect of statistical problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

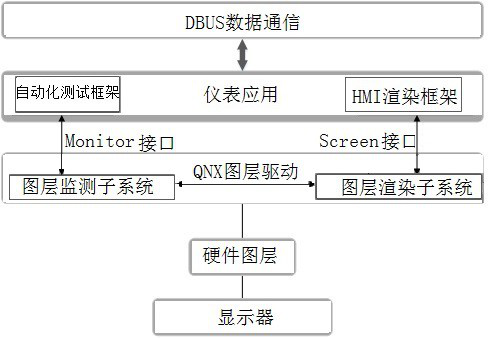

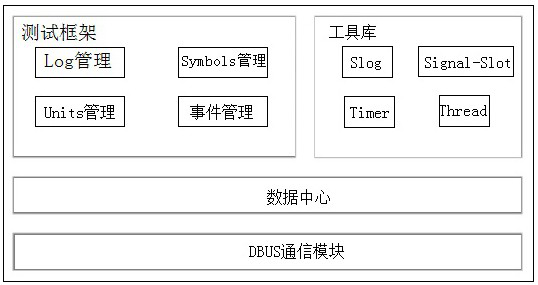

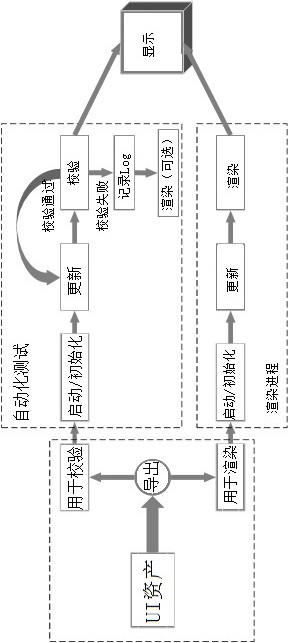

[0034] Embodiment: A method of HMI simulation and automatic verification based on QPIC, in this solution, two clusters are included, such as figure 1As shown, the left side is the automated test framework, and the right side is the normal HMI rendering application. The two applications are completely independent and receive the DBUS signal of the same protocol. This is to ensure that the HMI rendering process starts a certain function while the automation The test framework can also activate the verification function synchronously. The HMI rendering process flashes each frame display in the layer rendering subsystem through ScreenAPI. In the automated test framework, it will call the registration and monitoring of the QPIC component in the layer monitoring subsystem. The interface cyclically monitors the verification results, and actually obtains the currently displayed BUFFER and calculates the CRC verification value. This is the function implemented by the qgms_monitor servic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com