Automatic material overturning device for electron beam irradiation production and turnover treatment system

A technology of electron beam irradiation and automatic material turning, which is applied in the direction of irradiation device, transportation and packaging, conveyor objects, etc., can solve the problems of high labor cost, low turning speed, and reduced processing efficiency of the processing system, so as to reduce labor costs. cost, efficiency improvement, uniformity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

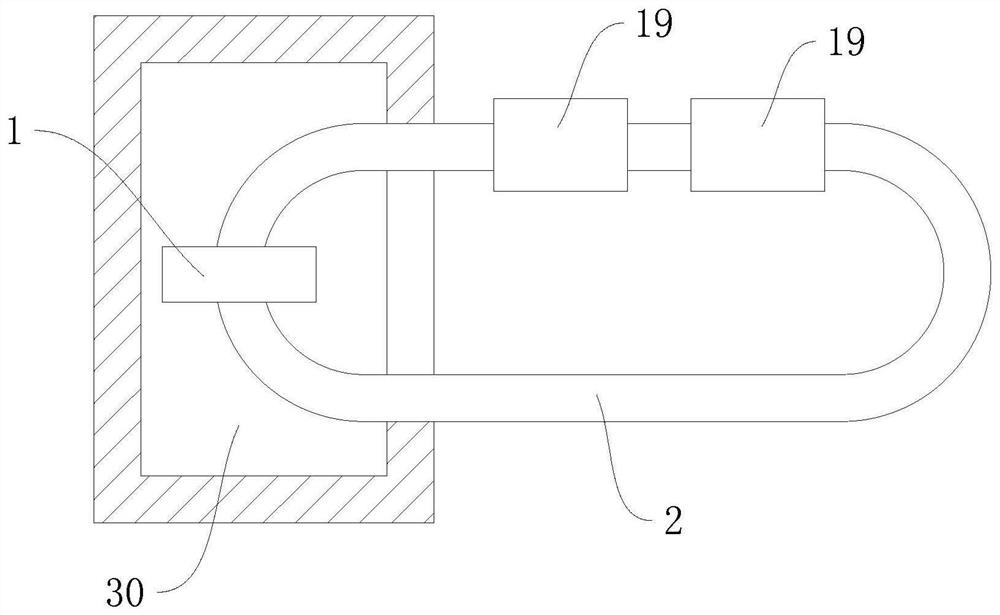

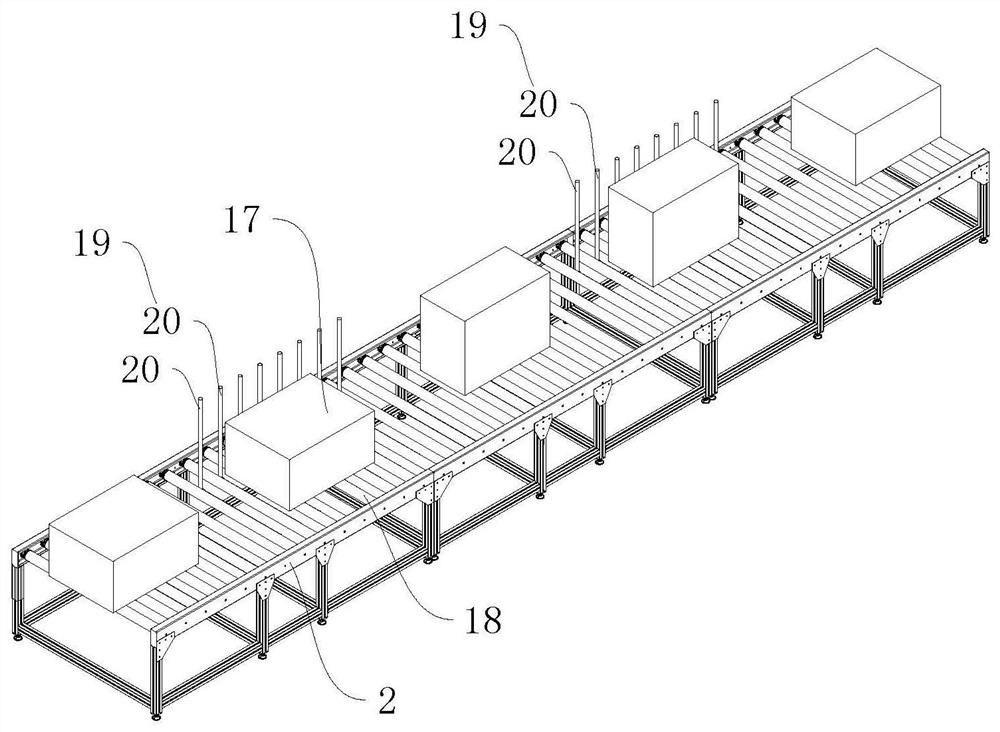

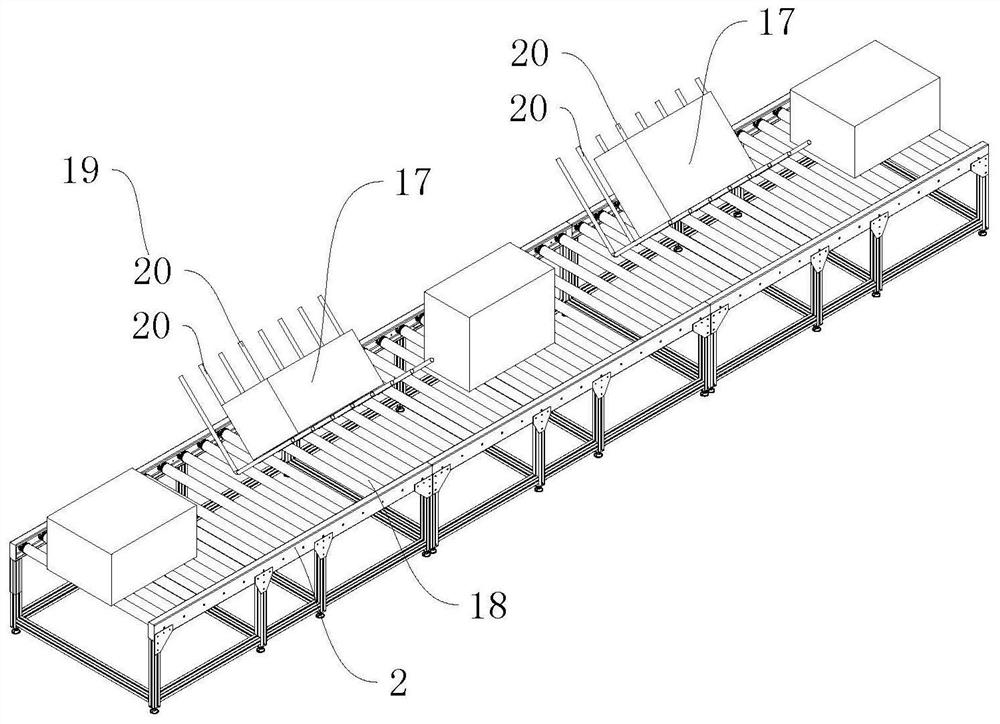

[0046] This embodiment discloses an electron beam irradiation production turnover processing system, such as Figure 1-4 and Figure 9 As shown, based on the conveyor belt 2 in a closed-loop structure, the goods 17 are prevented from being conveyed circularly above the conveyor belt 2. The conveyor belt 2 is formed by arranging a number of feeding rollers 18. material device, two sets of automatic turning devices are distributed along the direction of the feeding belt, capable of turning over the front and back sides of the goods 17; it also includes an electron beam irradiation system, the irradiation chamber 30 of the electron beam irradiation system passes through the conveyor belt 2 during transportation, For radiation shielding and protection, the electron beam irradiation system includes an irradiation box 1, which is installed above the conveyor belt 2, electron beams are emitted from the bottom of the irradiation box 1, and the goods 17 on the conveyor belt 2 are irrad...

Embodiment 2

[0049] This embodiment discloses a production turnover processing system for electron beam irradiation. On the basis of Embodiment 1, the automatic material turning device is optimized and referred to Figure 1-6 shown in detail.

[0050] Automatic material turning device comprises material turning assembly 19, is installed on the conveyer belt 2 that is arranged by several feeding rollers 18, and material turning assembly 19 comprises material turning frame 20, and the partial structure of material turning frame 20 passes between feeding rollers 18. through, so that the goods 17 above can be supported and turned over; the turning frame 20 has a number of turning bars 201 bent at right angles, and two supporting seats 21 and two connecting rods 22 are installed on the lower part of the feeding roller 18, Two support bases 21 are fixedly installed on the lower both sides of the feed roller 18, one end of the connecting rod 22 is hinged to the support base 21, and the other end ...

Embodiment 3

[0058] This embodiment discloses a protection device for goods 17 irradiated by electron beams, and the protection device can be installed and used in an electron beam irradiation production turnover processing system in the above-mentioned embodiments;

[0059] refer to Figure 10 As mentioned above, the protective device includes a protective plate 4 and a driving mechanism 6. The protective plate 4 is located at the electron beam emitting end of the radiation box. Generally, the irradiation box 1 is a triangular cover with a large bottom and a small top. Fixed, the electron beam is emitted from the emission end of the radiation box, and the cargo 17 below is irradiated; the protective plate 4 is located at the emission end of the lower part of the irradiation box 1; The beam is shielded, generally by a lead plate that is impenetrable to electron beam radiation.

[0060] Generally, corresponding cargo 17 conveying lines are installed in the irradiation system, which drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com