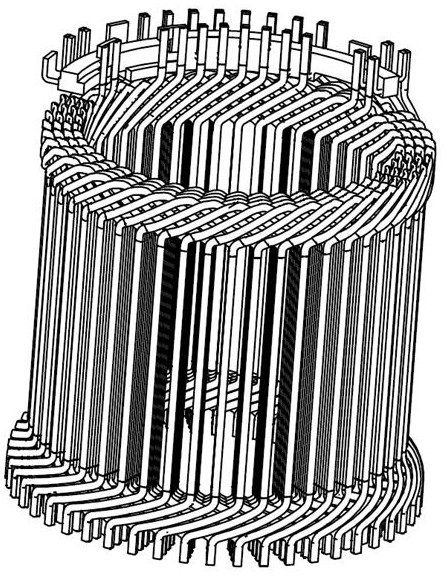

Multi-layer hairpin type flat wire winding, stator and motor

A flat wire winding and card issuing technology, applied in the electrical field, can solve the problems of difficult production and manufacturing, complicated structure of flat wire motor winding stator, etc., to save material cost and manufacturing cost, reduce complexity, and small proportion of winding space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

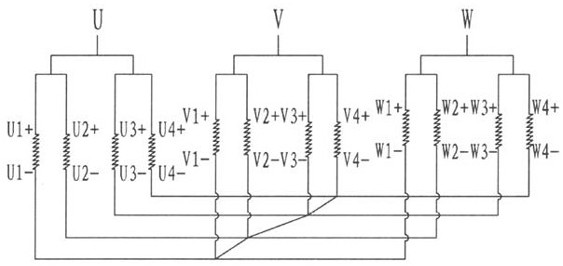

[0024] This embodiment takes 48 slots, 8 poles, 8 layers, three phases, 4 branches, and star connection as an example to expand the description. The lead-out line end is a three-phase lead-out line, and the tail ends of all the branches are connected together to form a star point line. terminal, forming a three-phase four-branch parallel star-connected armature, and then forming a motor.

[0025] Such as figure 2 As shown, the embodiment of the present invention is illustrated by taking 48 slots, 4 pole pairs, 4 parallel branches per phase, and 8 conductor layers per slot. The implementation method is:

[0026] The flat copper wire wave winding armature winding of this embodiment has an 8-layer wave winding structure, and the winding lead-out terminals U1+, U2+, U3+, U4+, U1-, U2-, U3-, U4-, V1+, V2+, V3+, V4+, V1-, V2-, V3-, V4-, W1+, W2+, W3+, W4+, W1-, W2-, W3-, W4- respectively correspond to the 4 branches of UVW three-phase, the suffix is "+ " are respectively conne...

Embodiment 2

[0042] According to Embodiment 1, the connection method of the four branches of each phase may be that all the branches of the same phase are connected end-to-end to form a branch, and then a star connection or a delta connection is implemented.

Embodiment 3

[0044] According to Embodiment 1, the connection method of the four branches of each phase can be that two branches of the same phase are first connected in series and then connected in parallel, that is, U1 and U3 are connected in series, U2 and U4 are connected in series, and U1, U3, U2 and U4 are connected in parallel to form two branches. , and then implement star connection or delta connection form.

[0045] In the multi-layer hairpin flat wire winding stator of the present invention, the long-distance or short-distance connection occurs only when the cross-layer transposition is to the equivalent slot of the adjacent slot, so that the head end and tail end of the branch are located along the The innermost layer and the outermost layer in the radial direction of the armature, a single branch of each phase will pass through the equivalent positions of all slots and layers of the phase, and each branch is spirally connected along the radial direction of the stator circumfere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com