Coiling machine winding drum with complementary double hydraulic jaws

A dual hydraulic, complementary technology, applied in metal rolling, manufacturing tools, metal processing equipment, etc., to achieve the effect of increasing clamping pressure and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the protection of the present invention.

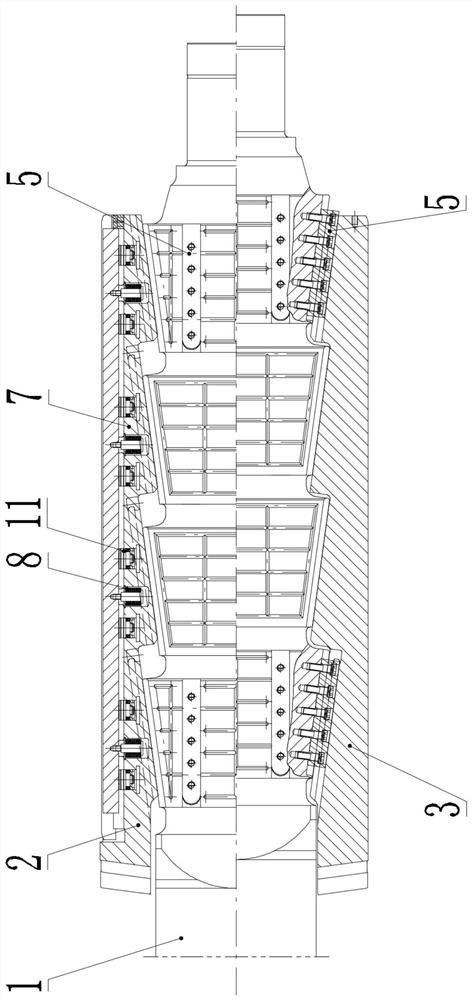

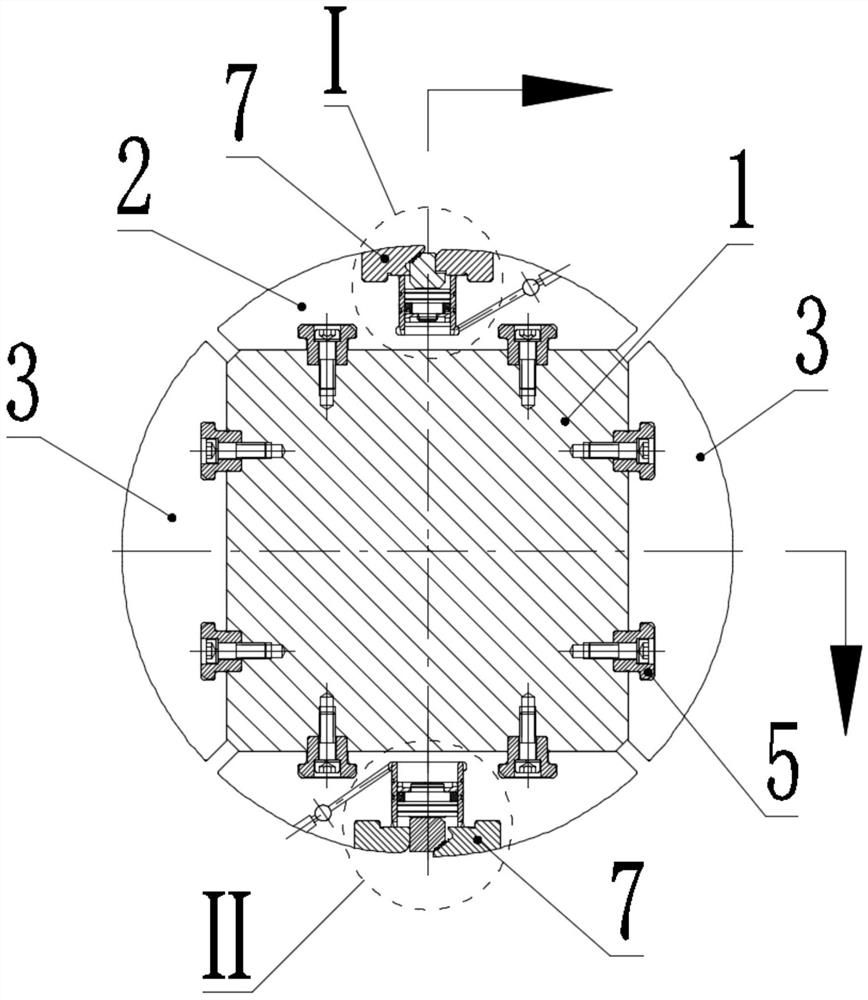

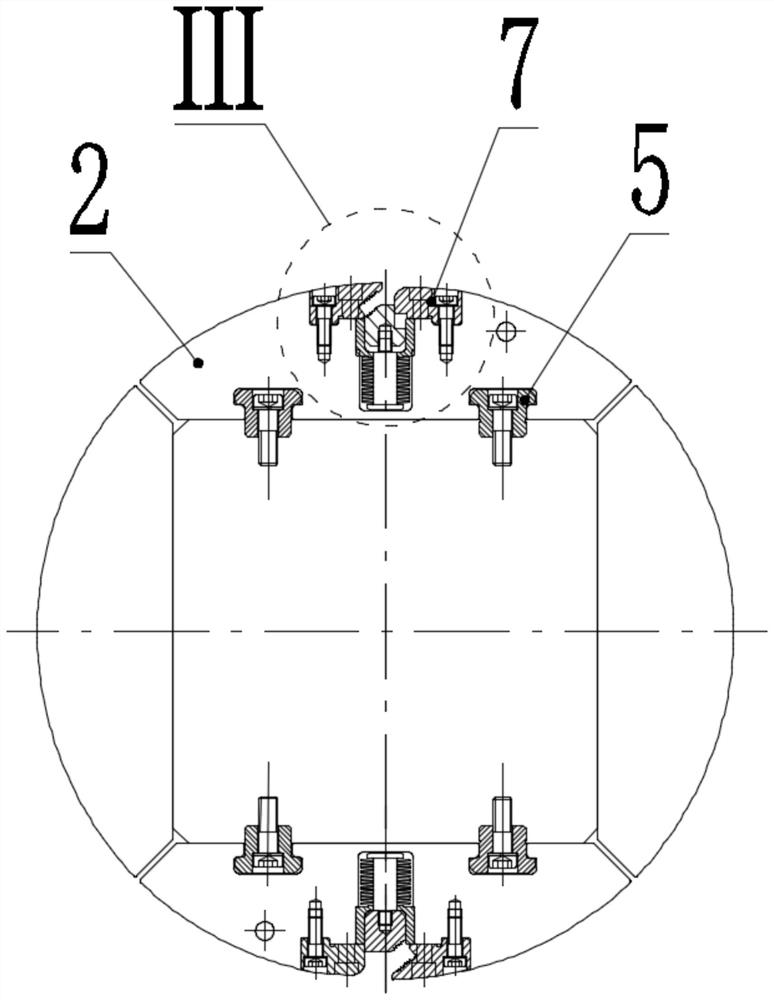

[0028] like Figure 1-3 As shown, the coiled machine barrel of the complementary double hydraulic jaw according to an embodiment of the present invention, includes a prinical shaft 1, and the pyramid shaft 1 is attached to the upper and lower and lower active attachment of the jaw sector plate 2, and the pyramid is left. The active connection is a sector plate 3, the jaw sector plate 2 and the arc surface of the top of the sector plate 3 are in the same circumferential surface, and the four-stage four-stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com