Automatically adjustable drying plate of digital printing machine

A digital printing machine, automatic adjustment technology, applied in the direction of printing, printing devices, color TV parts, etc., can solve the problems of poor drying effect, inability to realize remote operation, inability to automatically adjust height, etc., to ensure uninterrupted , Guarantee the effect of firmness and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

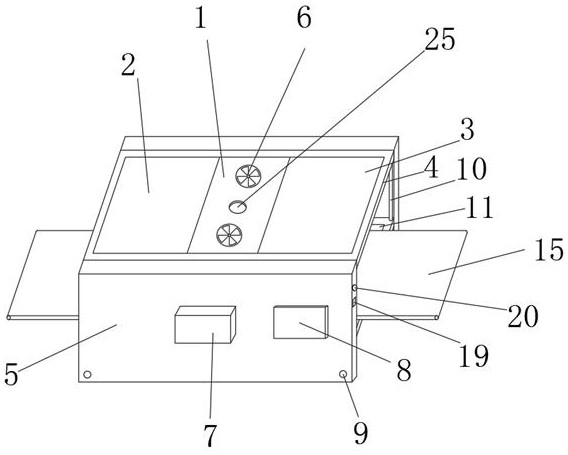

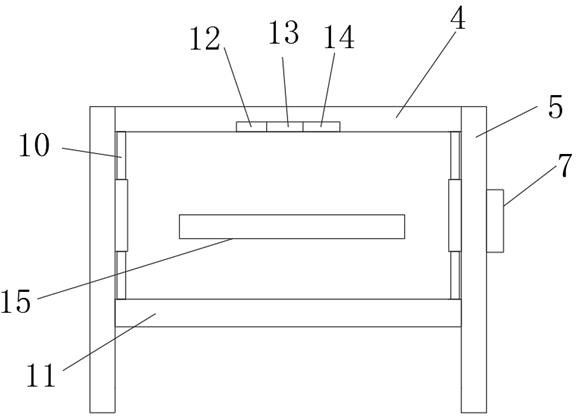

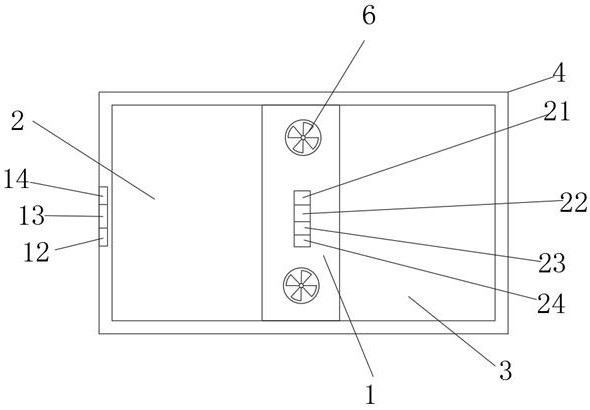

Embodiment 1

[0021] see figure 1 , 2 , an automatically adjustable drying plate of a digital printing machine, including a fixed plate A1, two exhaust fans 6 are fixed on the top of the fixed plate A1 by bolts, the exhaust fans 6 are evenly distributed up and down, a projector 25 is arranged between the exhaust fans 6, and the fixed plate The bottom of A1 is fixed with a temperature sensor B21, a humidity sensor B22, a scanner 23 and an image collector 24. The temperature sensor B21, the humidity sensor B22, the scanner 23 and the image collector 24 are evenly distributed front and back, and the model of the image collector 24 It is: EB-LINKEB-I350-T2-P, the model of the projector 25 is: DHNDM6300, there is a conveyor belt 15 under the temperature sensor B21, humidity sensor B22, scanner 23 and image collector 24, and the model of the conveyor belt 15 is: NN- 150, the conveyor belt 15 is fixed on the fixed plate B5 through the bearing, the drying plate C11 is arranged under the conveyor b...

Embodiment 2

[0024] see figure 1 , 2, 3, 4, an automatically adjustable drying plate of a digital printing machine, including a casing 4, the front and rear sides of the casing 4 are provided with fixing plates B5, and the left side of the bottom of the casing 4 is embedded with a temperature sensor A12 The models of the humidity sensor A13 and the distance sensor 14, the temperature sensor A12 and the temperature sensor B21 are both: pt100, the models of the humidity sensor A13 and the humidity sensor B22 are both: HIH3605, and the model of the distance sensor 14 is: BI10-M30-AD4X, The temperature sensor A12, the humidity sensor A13 and the distance sensor 14 are evenly distributed front and back, and the control box 7 is arranged under the front side of the fixed plate A1, and the inside of the control box 7 is provided with a controller 16, a transformer 17 and a wireless port 18, the controller 16, and the transformer 17 And the wireless port 18 is evenly distributed on the left and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com