Novel PE drain pipe and production equipment thereof

A technology for production equipment and drainage pipes, which is applied in the field of new PE drainage pipes and its production equipment, can solve the problems of easy aging of polyethylene pipes and unfavorable long-term use, and achieve good chemical stability, resistance to general organic solvents, increased resistance The effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A new type of PE drainage pipe proposed by the present invention is composed of the following raw materials in weight ratio:

[0029] 60 parts of high-density polyethylene, 70 parts of low-density polyethylene, 3.5 parts of white carbon black, 3 parts of calcium carbonate, 3 parts of nano-kaolin, 0.9 parts of polyacrylamide, 1.2 parts of flame retardant, 4 parts of zinc oxide, 2 parts of anti-aging agent And 7 parts of antioxidant.

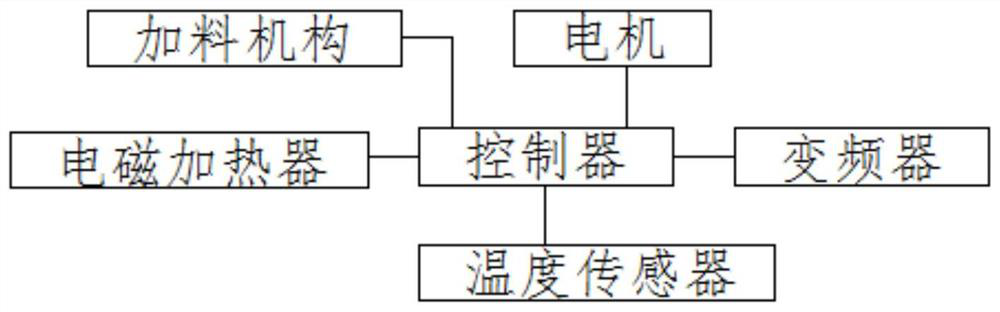

[0030] A new type of PE drainage pipe, its production equipment includes: frequency converter, feeding mechanism, electromagnetic heater, temperature sensor, motor and controller;

[0031] The controller is connected to the frequency converter by communication, and the controller is used to control the frequency converter; the frequency converter is connected to the motor by communication, and the frequency converter is used to change the working power frequency mode of the motor to control the motor;

[0032] The electromagnetic heater is...

Embodiment 2

[0040] A new type of PE drainage pipe, which is composed of raw materials with the following weight ratio:

[0041] 75 parts of high-density polyethylene, 82.5 parts of low-density polyethylene, 3.7 parts of white carbon black, 5 parts of calcium carbonate, 4.5 parts of nano-kaolin, 1.1 parts of polyacrylamide, 1.8 parts of flame retardant, 9 parts of zinc oxide, 3.5 parts of anti-aging agent parts and 8.5 parts of antioxidants.

[0042] A new type of PE drainage pipe, its production equipment includes: frequency converter, feeding mechanism, electromagnetic heater, temperature sensor, motor and controller;

[0043] The controller is connected to the frequency converter by communication, and the controller is used to control the frequency converter; the frequency converter is connected to the motor by communication, and the frequency converter is used to change the working power frequency mode of the motor to control the motor;

[0044] The electromagnetic heater is connected...

Embodiment 3

[0052] A new type of PE drainage pipe, which is composed of raw materials with the following weight ratio:

[0053] 83 parts of high-density polyethylene, 95 parts of low-density polyethylene, 3.8 parts of white carbon black, 6 parts of calcium carbonate, 5.5 parts of nano kaolin, 1.2 parts of polyacrylamide, 2.1 parts of flame retardant, 12 parts of zinc oxide, 4.5 parts of anti-aging agent And 9 parts of antioxidant.

[0054] A new type of PE drainage pipe, its production equipment includes: frequency converter, feeding mechanism, electromagnetic heater, temperature sensor, motor and controller;

[0055]The controller is connected to the frequency converter by communication, and the controller is used to control the frequency converter; the frequency converter is connected to the motor by communication, and the frequency converter is used to change the working power frequency mode of the motor to control the motor;

[0056] The electromagnetic heater is connected to the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com