PC/PA composite material with relatively high light transmittance and preparation method thereof

A composite material and light transmittance technology, applied in the field of polymer materials, can solve the problems of limited application, no large-scale industrial production, and high price of block copolymerized PC, and achieve the effect of good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Preparation of PC / PA composite material A with higher light transmittance

[0023] Raw materials: 95 parts of PC resin, 5 parts of PA10I resin, 0.2 part of antioxidant, and 0.2 part of lubricant.

[0024] 1. Weigh 47.5 kg of PC resin, 2.5 kg of dried PA10I resin, 0.1 kg of antioxidant, and 0.1 kg of lubricant, add them to the high-speed mixer, mix at low speed for 1 minute, then mix at high speed for 2 minutes, and release the material;

[0025] 2. Feed the mixed material into the twin-screw extruder, and after the material comes out of the die of the extruder, it is dragged, cooled, dried, and pelletized to obtain the PC / PA composite material.

[0026] The temperature of each zone of the twin-screw extruder is set as follows: the temperature in the first zone is 180-185°C, the temperature in the second zone is 200-255°C, the temperature in the third zone is 255-260°C, the temperature in the fourth zone is 255-260°C, and the temperature in the fifth zone is 2...

experiment example 1

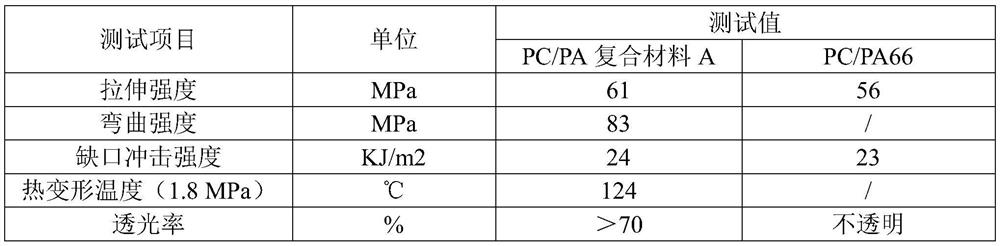

[0027] Experimental example 1: PC / PA composite material A product performance test with high light transmittance

[0028] After drying the PC / PA composite material A prepared in Example 1, use an injection molding machine to make various standard specimens, and place it for 24 hours for testing; injection molding machine temperature: 265°C, 265°C, 270°C; injection speed 68g / s, injection molding The time is 12s, the injection pressure is 43MPa, the holding pressure is 36MPa, and the holding time is 30s.

[0029] Table 1 Test results of PC / PA composites

[0030]

[0031] Note: PC / PA66 test data comes from CN103937194A Example 4

Embodiment 2

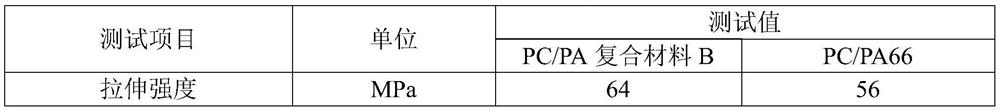

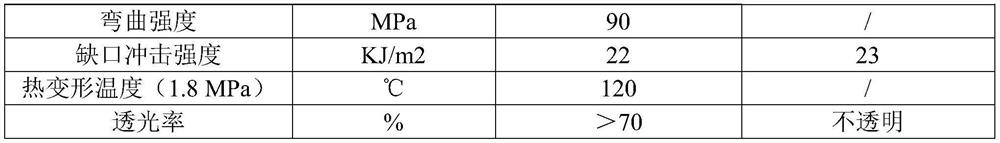

[0032] Embodiment two: the preparation of PC / PA composite material B with higher light transmittance

[0033] Raw materials: 90 parts of PC resin, 10 parts of PA10I resin, 0.4 part of antioxidant, and 0.4 part of lubricant.

[0034] 1. Weigh 45 kg of PC resin, 5 kg of dried PA10I resin, 0.2 kg of antioxidant, and 0.2 kg of lubricant, add them to the high-speed mixer, mix at low speed for 1 minute, then mix at high speed for 2 minutes, and release the materials;

[0035] 2. Feed the mixed material into the twin-screw extruder, and after the material comes out of the die of the extruder, it is dragged, cooled, dried, and pelletized to obtain the PC / PA composite material.

[0036] The temperature of each zone of the twin-screw extruder is set as follows: the temperature in the first zone is 180-185°C, the temperature in the second zone is 200-255°C, the temperature in the third zone is 255-260°C, the temperature in the fourth zone is 255-260°C, and the temperature in the fifth zo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com