Cooling control method and circulating cooling system for mass concrete structure in water body

A large-volume concrete and cooling control technology, which is applied in the direction of cooling fluid circulation devices, infrastructure engineering, household refrigeration devices, etc., can solve problems such as large energy consumption, high pressure of refrigeration units, failure to meet the civilized construction requirements of energy saving and environmental protection, etc. , to achieve the effects of improving utilization, ensuring quality and efficiency, and ensuring controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

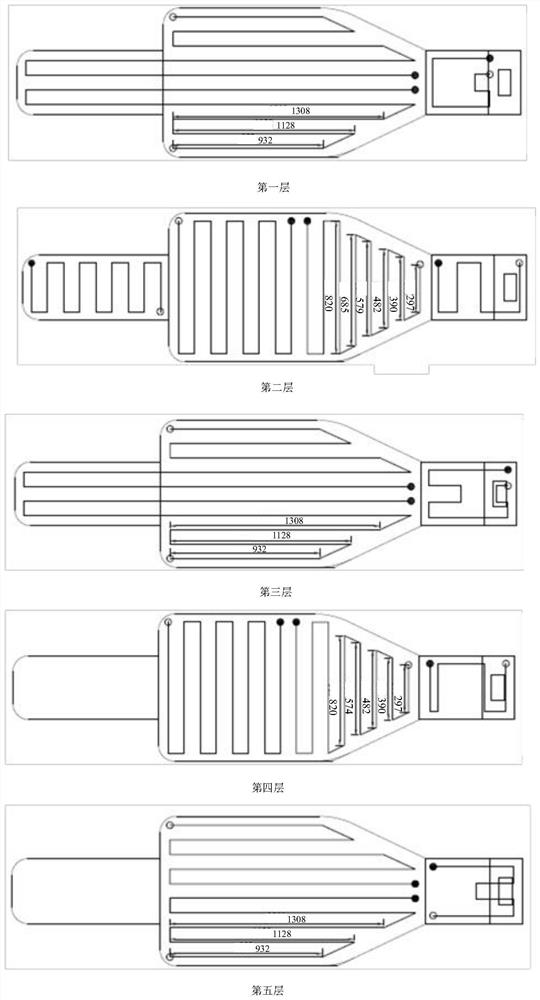

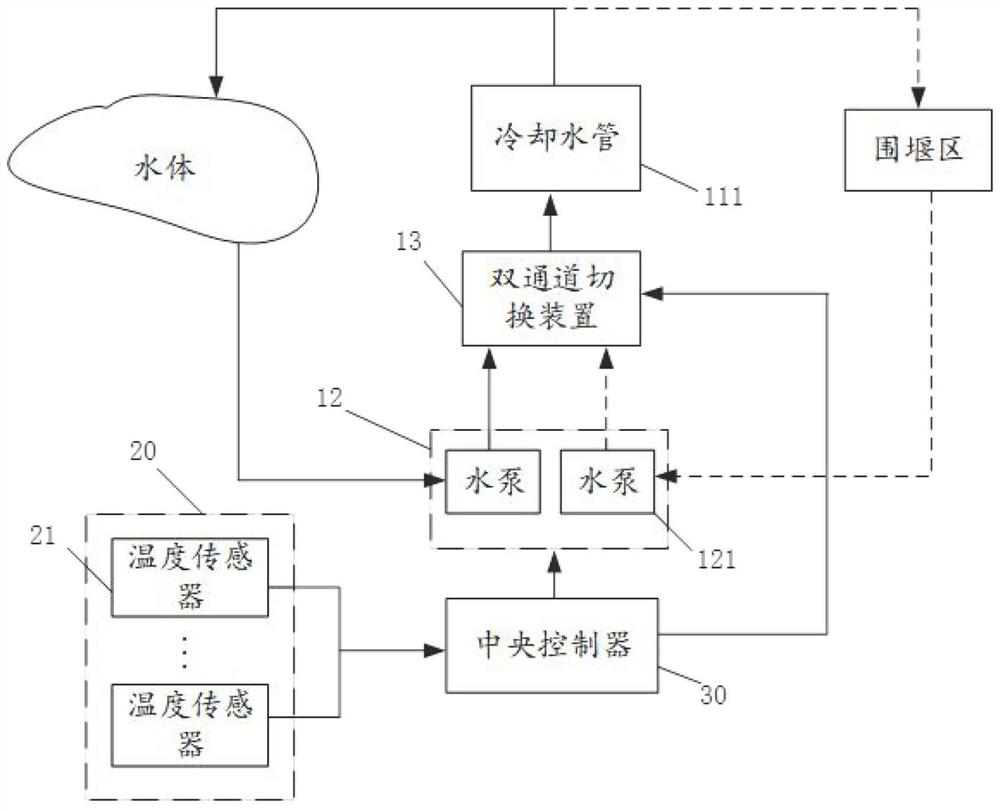

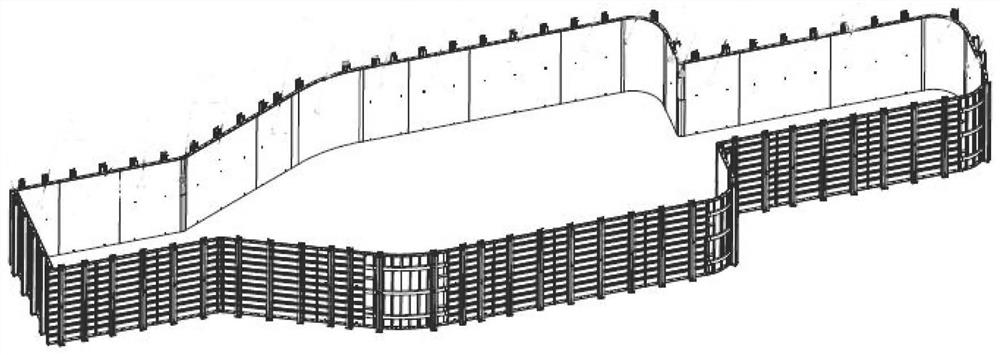

[0044] See figure 1 , figure 1 It is a structural schematic diagram of the circulating cooling system of the mass concrete structure in the water body provided by the first embodiment. The circulating cooling system includes: a circulating cooling water pipe system 10, a temperature sensor group 20 and a central controller 30; the central controller 30 is respectively connected to the circulating cooling water pipe system 10 and the temperature sensor group 20; wherein,

[0045] The temperature sensor group 20 includes a plurality of temperature sensors 21 arranged in the mass concrete structure for sending real-time temperature information to the central controller 30;

[0046] Specifically, a plurality of temperature sensors 21 are respectively arranged at each temperature measuring point in the formwork of the mass concrete structure, preferably, the temperature sensors 21 are wireless temperature sensors connected to the central controller 30 through wireless communicatio...

Embodiment 2

[0061] See Figure 4 , Figure 4 It is a schematic flow chart of the cooling control method of the mass concrete structure in the water body provided by the second embodiment. The cooling control method takes the central controller as the execution subject and includes the following steps:

[0062] Step S11, when concrete is poured, after the concrete covers the pre-embedded cooling water pipes, the water in the water body and the water stored in the cofferdam area are successively extracted as circulating cooling water to circulate the cooling water pipes, and according to the real-time obtained The temperature at each temperature measuring point regulates the water flow rate, so that the temperature difference between the inlet and outlet water of the cooling water pipe is within the preset temperature difference range.

[0063] During concrete implementation, the temperature of concrete entering the mold should be controlled during the concrete pouring construction process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com