Extended longitudinally scavenged motor

An engine and diesel engine technology, applied in gaseous engine fuels, engine components, combustion engines, etc., can solve problems such as increased emission value, high emission value, engine high efficiency and low emission work, and achieve precise adjustment, high-quality combustion effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

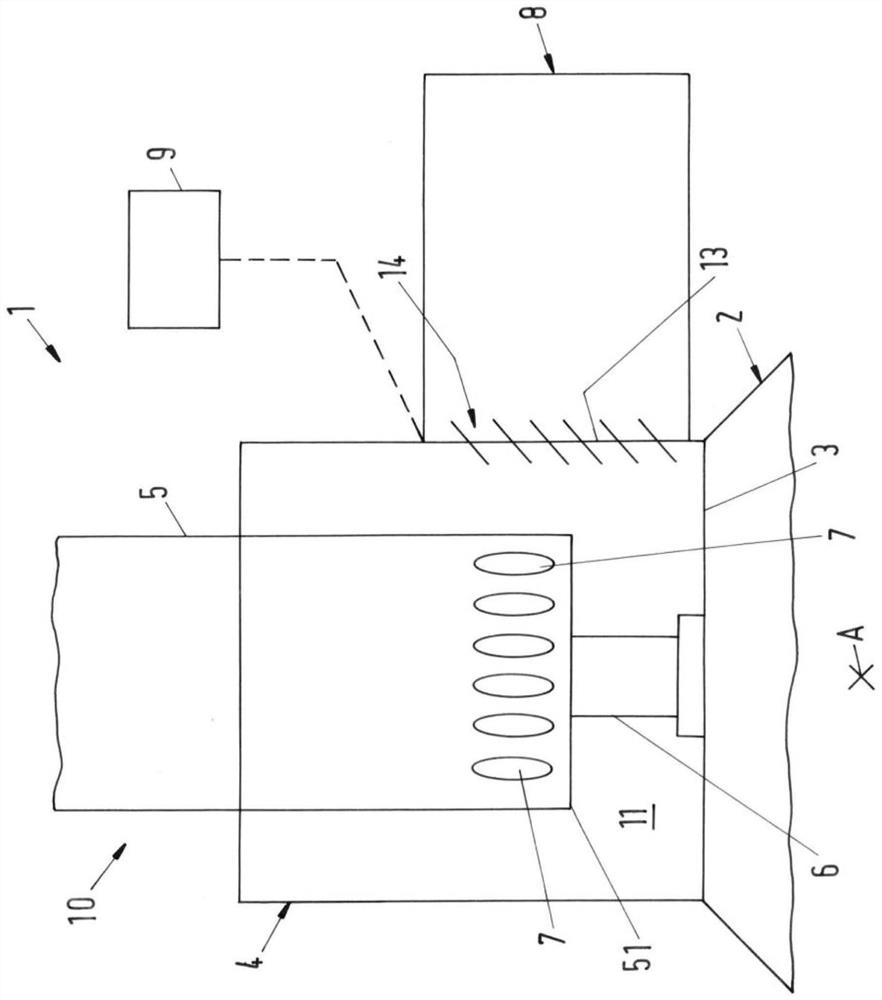

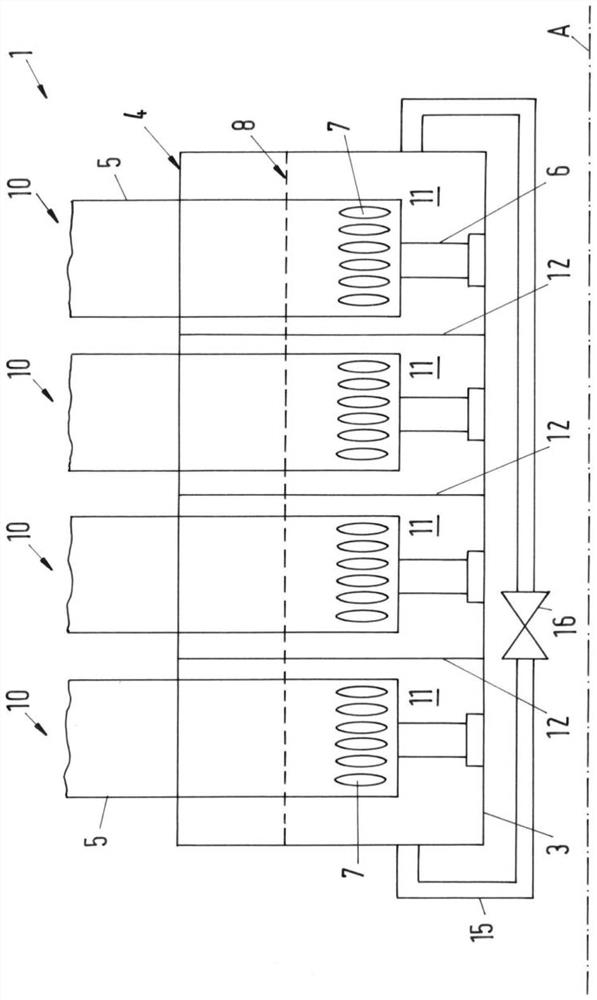

[0043] figure 1 A schematic cross-sectional view of an embodiment of a longitudinally scavenged crosshead large engine according to the invention is shown, which is designated as a whole by the reference numeral 1 . This section is perpendicular to the longitudinal direction A defined by the direction in which the crankshaft of the large engine 1 extends. figure 2 A schematic sectional view of this embodiment in a section along the longitudinal direction A is shown.

[0044] A large engine 1 comprises at least one but usually a plurality of cylinders 10 in which the combustion process takes place. exist figure 2 In, four cylinders 10 are shown as exemplary features. Each cylinder 10 comprises a cylinder liner 5 in which, in a manner known per se, a piston (not shown) is arranged so as to be able to move between an upper and a lower reversing point The piston moves back and forth in the direction of the cylinder axis, and the upper side of the piston defines a combustion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com