Method for positioning and detecting crack defects of material

A detection method and defect technology, which is applied in the analysis of materials, the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, measuring devices, etc., can solve the problems of increasing the cost of ultrasonic testing technology and the difficulty of operation, and achieve simplified tracking and length calculations , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings. This embodiment is only used to explain the present invention, and does not constitute a limitation to the protection scope of the present invention.

[0051] A method for locating and detecting material crack defects, comprising the following steps:

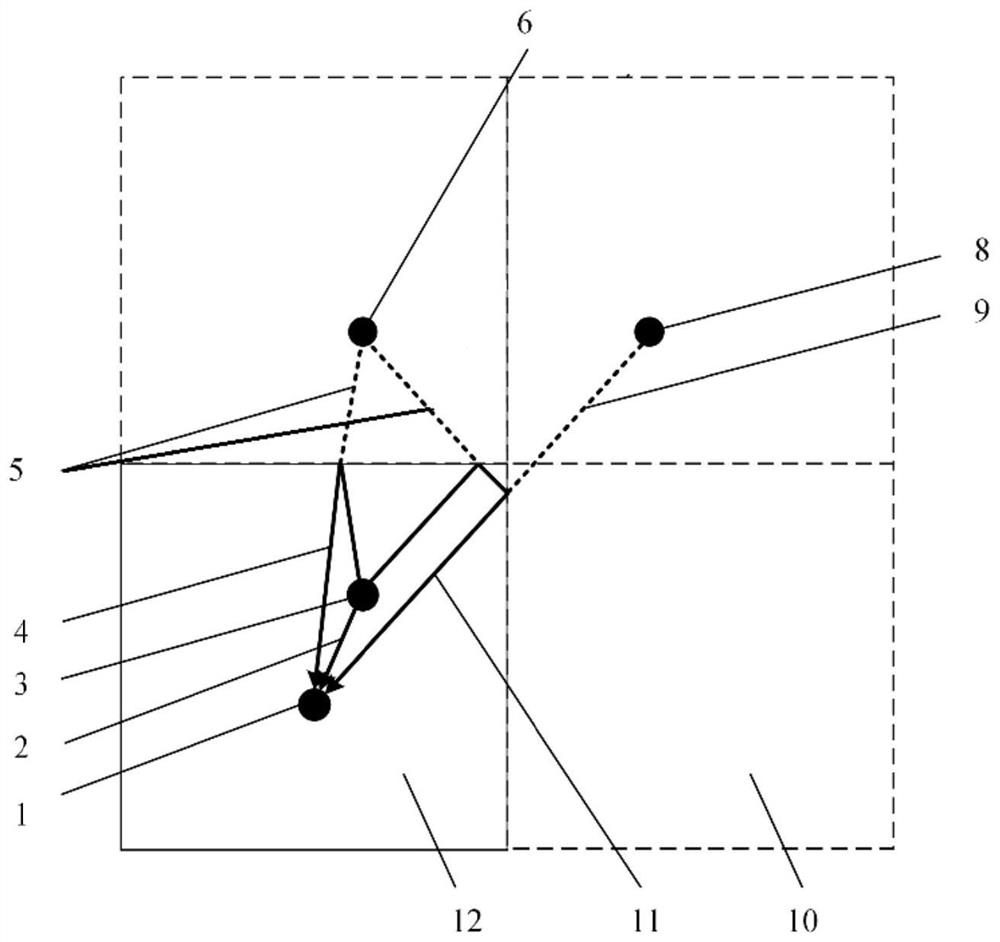

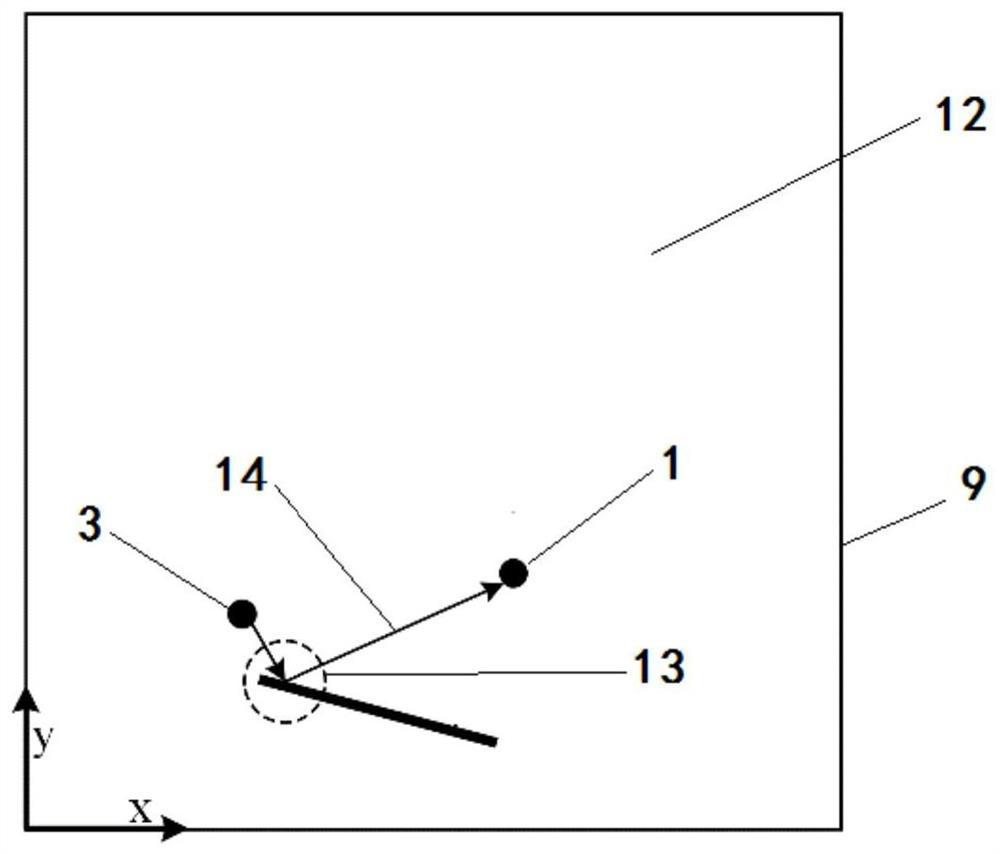

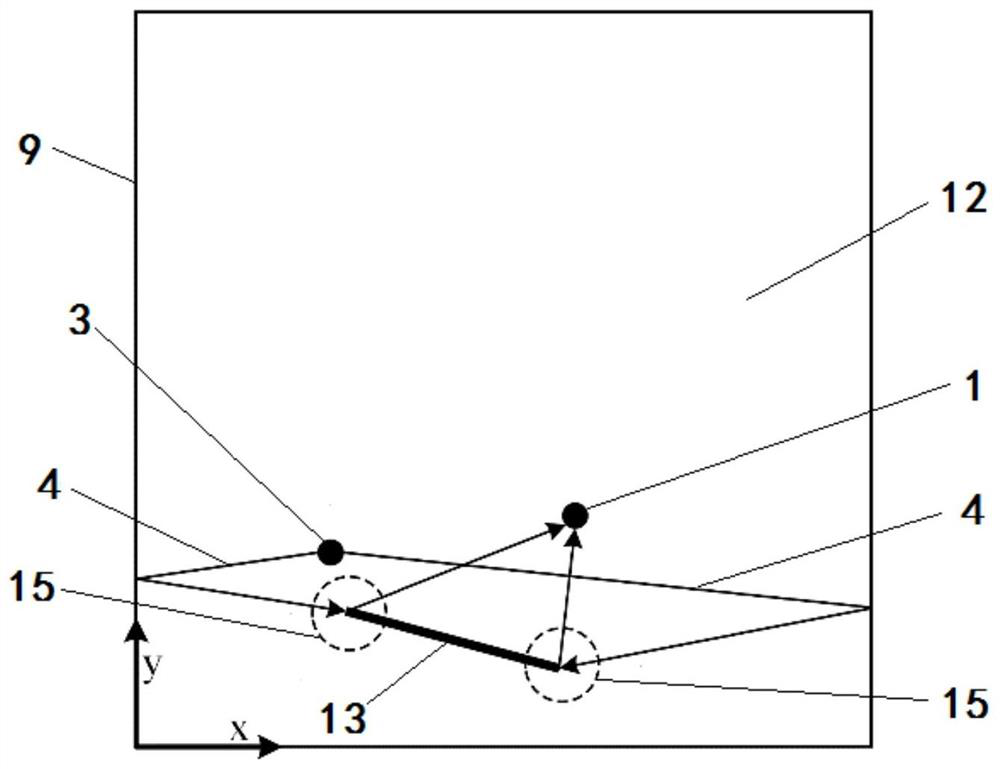

[0052] Step 1: According to the geometric shape of the material structure 12 to be detected, determine multiple paths for guided wave propagation, including the primary reflection path 4 and the secondary reflection path 11 with the material boundary 9;

[0053] Step 2: In the material structure 12, the actuator 3 and the sensor 1 are set to transmit and receive guided wave signals;

[0054] Step 3: Use the matching pursuit guided wave decomposition method to determine the time delay of the waveforms of different paths recorded in the received signal;

[0055] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com