Dustproof film expanding machine

A film expansion machine, dust-proof technology, applied in the field of film expansion machine, can solve problems such as affecting the performance of the machine and accumulating dust on the body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

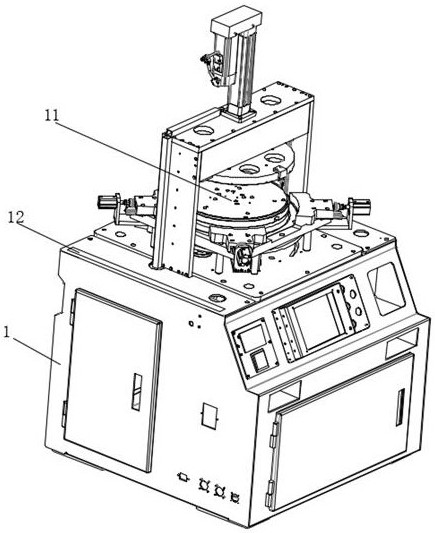

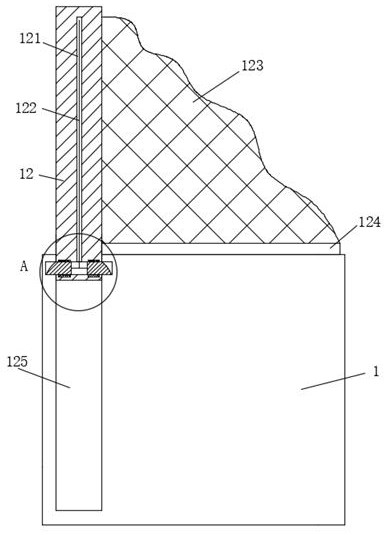

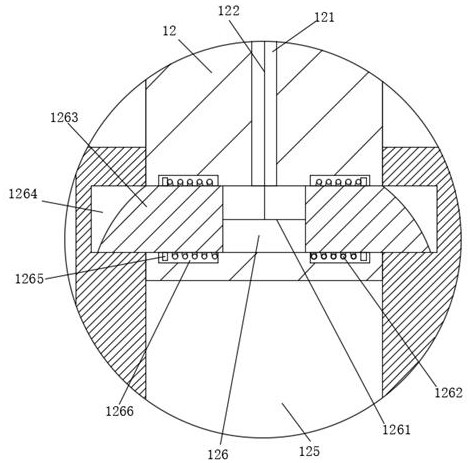

[0033] see Figure 1-5 , a dust-proof film expanding machine, comprising a body 1, a body 11 arranged on the body 1 and in an exposed shape, the body 1 located on one side of the body 11 is provided with a hidden type for the body 11 to prevent The dust-proof mechanism includes a hidden groove 125, a dust-proof plate 12 and a sealing frame 124. The hidden groove 125 is arranged on one side of the fuselage 11; the dust-proof plate 12 can slide up and down. connected in the hidden groove 125; the sealing frame 124 is U-shaped, and the sealing frame 124 is rotatably connected in the dustproof plate 12; wherein, the dustproof plate 12 is provided with a shrinkage groove matching the sealing frame 124 127, the bottom of the sealing frame 124 is rotatably connected with the shrinking groove 127, and a dust cover 123 is connected between the inner wall of the shrinking groove 127 and the frame of the sealing frame 124 and is used for dustproofing of the fuselage 11. The cover 123 is...

Embodiment 2

[0042] The same point with Example 1 is not repeated, and the difference with Example 1 is:

[0043] see Figure 6-7 , the sealing frame 124 includes a horizontal bar and a vertical bar. There are two vertical bars, and the vertical bars are symmetrically distributed at both ends of the horizontal bar. The vertical bars include a first bar 1242 and a second bar 1241. The end of a rod 1242 is provided with a chute 12422 for sliding connection of the second rod 1241, and a second spring 12421 for fixed connection and automatic contraction of the second rod 1241 is provided in the chute 12422. The second spring 12421 It is fixedly connected with the end of the corresponding second rod 1241, the dust cover 123 is fixedly connected with the horizontal rod and the vertical rod, respectively, and the first rod 1242 and the second rod 1241 are both provided with aligned and interconnected squeeze bars. Pressing groove, the cross-section of the pressing groove is convex, the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com