Crawler-type high-speed seeding or seed-metering method and device and seeding machine formed by same

A kind of seeding device and crawler-type technology, which is applied in the direction of hole sowing seeder, seeder parts, sowing, etc., can solve the problems of high failure rate, increased cost and manufacturing requirements, and extremely high precision requirements for the complexity of the sprocket structure. Advanced problems, to achieve the effect of improving the ability to adapt to harsh environments, ensuring quality, and simplifying the sprocket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

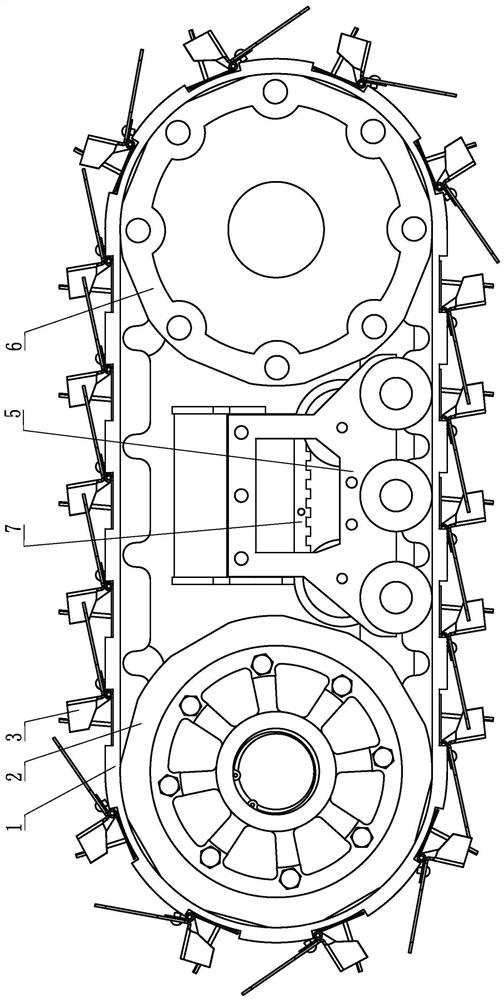

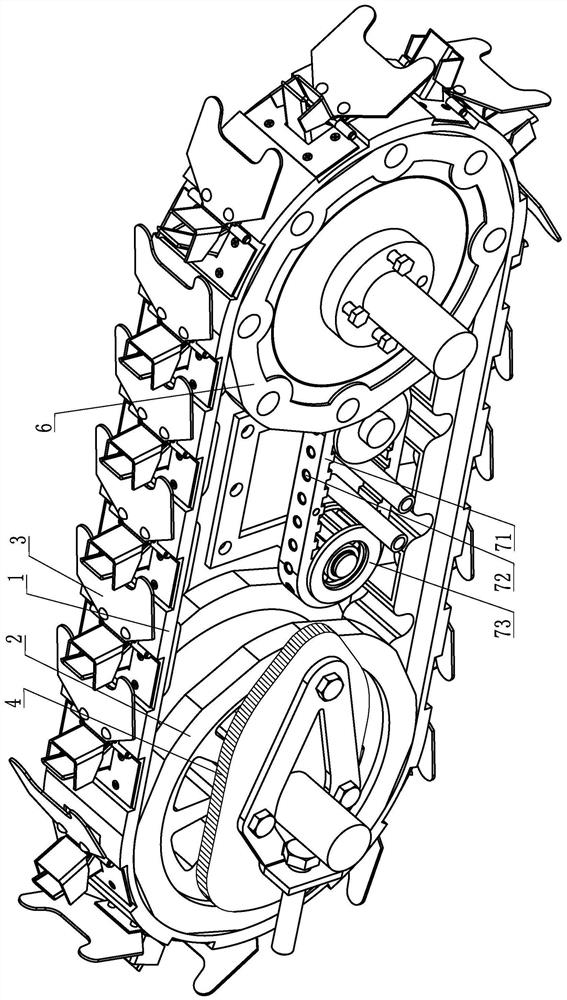

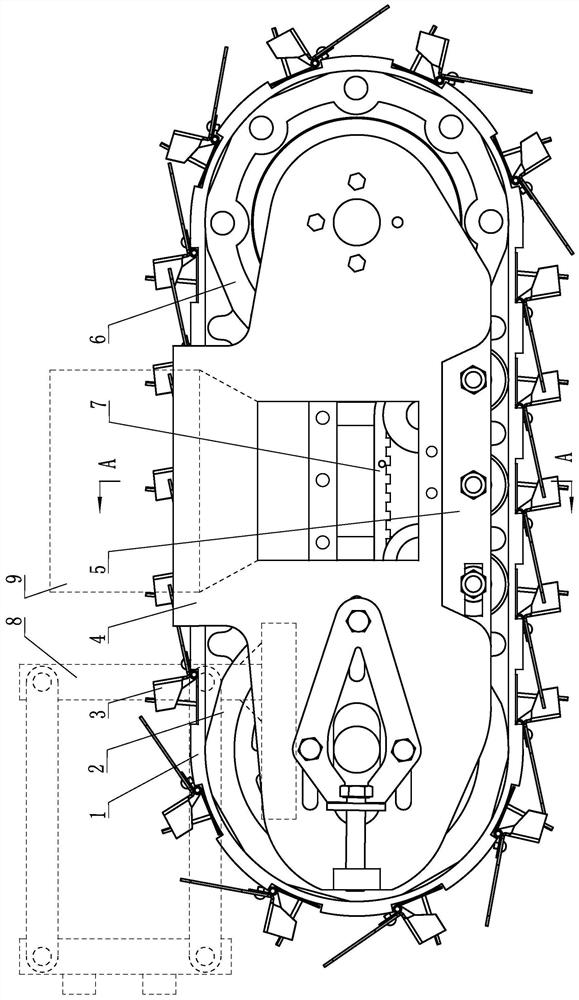

[0043] Embodiment 1: refer to Figure 1-11, is a structural schematic diagram of Embodiment 1 of the present invention, a sprocket mechanism composed of a sprocket and a chain is set, and the seeding mechanism is arranged on the chain of the sprocket mechanism, and the described seeding mechanism is an array of rows on the chain. Seed mouth or on-demand nozzle, the lower chain of the sprocket mechanism is provided with a horizontal section, and at least two or more seeding mechanisms are arranged on the horizontal section, and more than two seeding mechanisms perform seeding simultaneously or sequentially during travel , prolong the contact time of a single seeding mechanism with the ground, and at the same time, set a seed-taking mechanism independent of the sprocket in the sprocket mechanism, and throw seeds to the seed-setting mechanism arranged on the chain through the independent seed-taking mechanism.

[0044] In this embodiment, the specific crawler-type high-speed sowi...

Embodiment 2

[0052] Embodiment 2: refer to Figure 12 , is a structural schematic diagram of Embodiment 2 of the present invention. Compared with Embodiment 1, the difference of this embodiment is that the described seed wheel 71 is an endless rubber belt, and the described seed-taking hole 72 is arranged at the conveying On the belt-shaped body, a seed picker 78 is arranged in the seed-taking hole 72. The seed picker 78 is a seed spoon, and the seed spoon is installed in the seed-taking hole through a pin shaft and is provided with a return spring and a trigger. Fork, is provided with trigger 79 on the side of seed-taking mechanism 7, and this trigger 79 is the bump on the kind-taking type hole 72 on the kind-taking wheel 71 that takes kind or throws the bump on the traveling route, on the kind-taking wheel 71 On the route of taking or throwing seeds in the seed-taking hole 72, when the trigger swing lever touches the bump, the seed picker 78 changes state to realize taking or throwing se...

Embodiment 3

[0053] Embodiment 3: refer to Figure 13-14 , is a structural schematic diagram of Embodiment 3 of the present invention. Compared with Embodiments 1 and 2, the difference of this embodiment is that the described seed wheel 71 is an annular rubber belt, and the inner side of the rubber belt is provided with a transverse concave Groove can not only ensure a certain thickness of the rubber belt, but also can install the seed picking mechanism, and can adjust the expansion and contraction due to the deformation of the rubber belt during operation. The rubber belt is provided with a seed picker 78, which is a Cylindrical body, the cylindrical body is connected to the rubber belt through a pin shaft and can rotate. At the same time, the cylindrical body is provided with a return spring and a trigger swing lever. The described seed-taking hole 72 is arranged on the cylindrical body. Side is provided with trigger 79, and this trigger 79 is the bump on the seed-taking type hole 72 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com