Live-line installation method for low-voltage detachable lightning arrester

An installation method and lightning arrester technology are applied in the field of lightning arresters to achieve the effects of improving stability, facilitating installation, and improving emergency repair effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

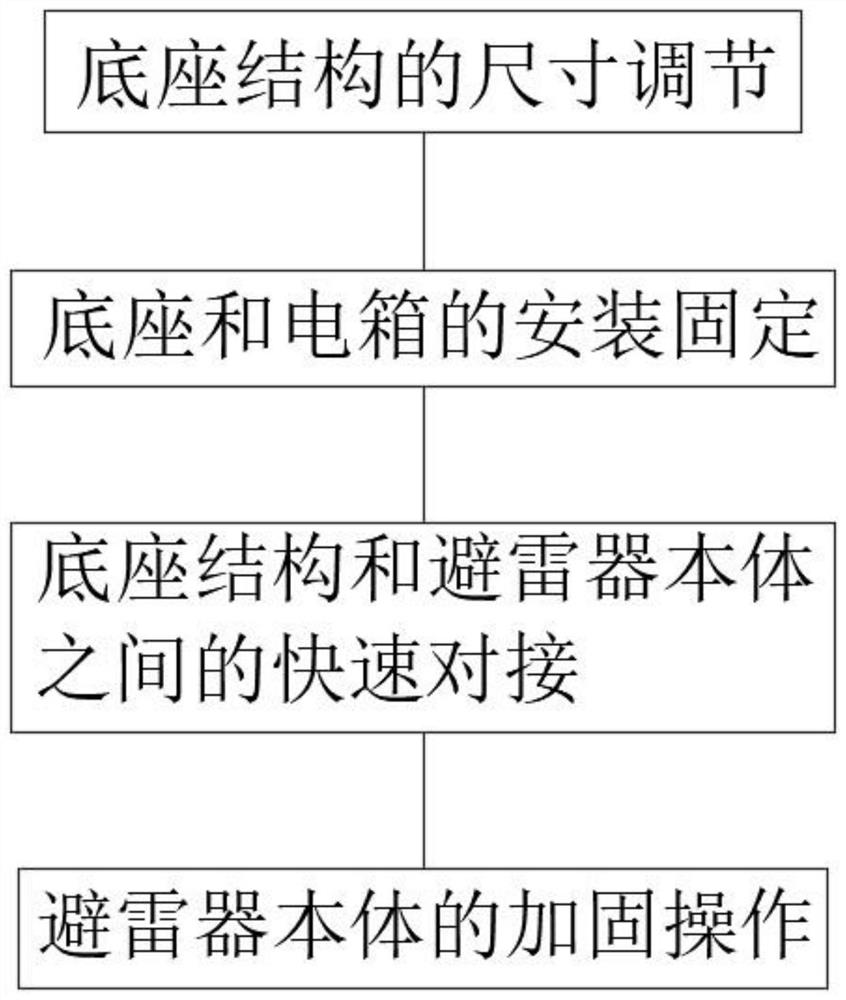

Method used

Image

Examples

Embodiment 1

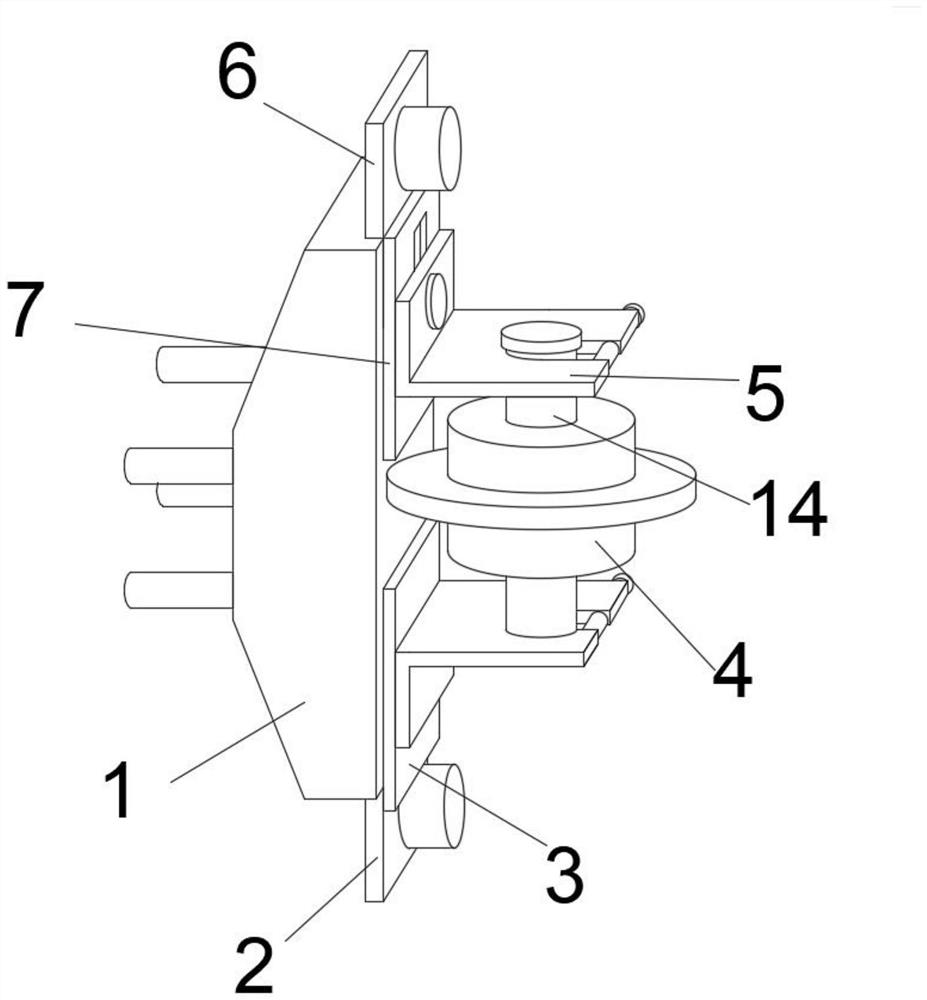

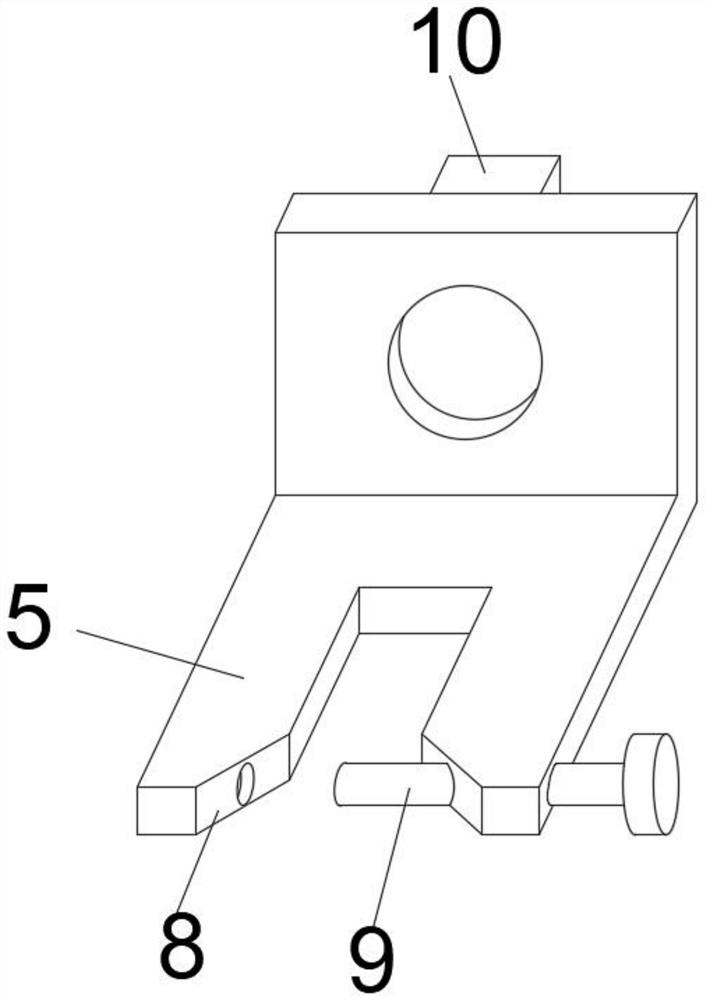

[0041] When the L-shaped card holder 5 is installed, the lifting blocks 10 at the rear ends of the two groups of L-shaped card holders 5 are respectively stuck in the lifting chute 12 of the second card board 7 and the first card board 3, and the L-shaped card is pulled longitudinally. seat 5, so that the lifting block 10 moves in the lifting chute 12, thereby adjusting the distance between the two groups of L-shaped card seats 5, and utilizing the adjustment of the distance between the two groups of L-shaped card seats 5, so that the two groups of L-shaped card seats Arrester bodies 4 of different lengths can be used between the decks 5 .

[0042] When the second clamping plate 7 and the first clamping plate 3 are installed, by clamping the second clamping plate 7 and the first clamping plate 3 in the connecting plate slot 19 of the ceramic base 1, the second clamping plate is screwed together by bolts. 7. The first clamping plate 3 and the ceramic base 1 are fixed, the inner...

Embodiment 2

[0045] When the lightning arrester body 4 is docked and installed, the elastic clip rods 14 at both ends of the lightning arrester body 4 are respectively stuck in the docking card slot 8 of the L-shaped card base 5, and the second card is inserted into the docking card slot 8 of the L-shaped card base 5. Bolt 9 is used to limit and fix the elastic clip bar 14. The other end of the docking slot 8 is an inclined plane structure. The middle position of the rear end of the L-shaped card seat 5 is equipped with a lifting block 10 for lifting and lowering. The second clamping plate 7 and the side of the first clamping plate 3 are Z-shaped structures, and one end of the second clamping plate 7 and the first clamping plate 3 is provided with a butt joint nozzle 13 .

[0046] Elastic clip bar 14 when in use, the lifting push rod 16 of elastic clip bar 14 is stuck on the surface of L-shaped deck 5, it is fixed, and the side of the second clip 7 and the first clip 3 is provided with Lif...

Embodiment 3

[0048] When the lifting jack 16 is in use, the spring buckle 17 is used to pull down the lifting jack 16, so that the lifting jack 16 and the elastic clamping rod 14 produce an elastic clamping structure, and cooperate with the washer at the bottom of the lifting jack 16 to carry out the L-shaped clamping seat 5 Clamping and fixing, the first clamping plate 3 is docked and fixed by the docking bayonet 13 and the first wire plate 2, and the inner side of one end of the elastic clamp rod 14 is movable with a lifting jack 16, and the elastic clamping rod 14 and the lifting jack 16 are Through the elastic connection of the spring buckle 17, two sets of limit rings 15 are installed at the lower side of the lift rod 16.

[0049] When the moving slider 18 is in use, the moving slider 18 is pulled by the transverse chute 20 of the arrester body 4, so that the moving slider 18 moves at the rectangular notch 21, thereby adjusting the distance between the two groups of moving sliders 18, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com