Surface acoustic wave device capable of suppressing transverse mode and manufacturing method thereof

A surface acoustic wave device, lateral mode technology, applied in electrical components, impedance networks, etc., can solve problems such as difficult application, increase the difficulty of lithography, and reduce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

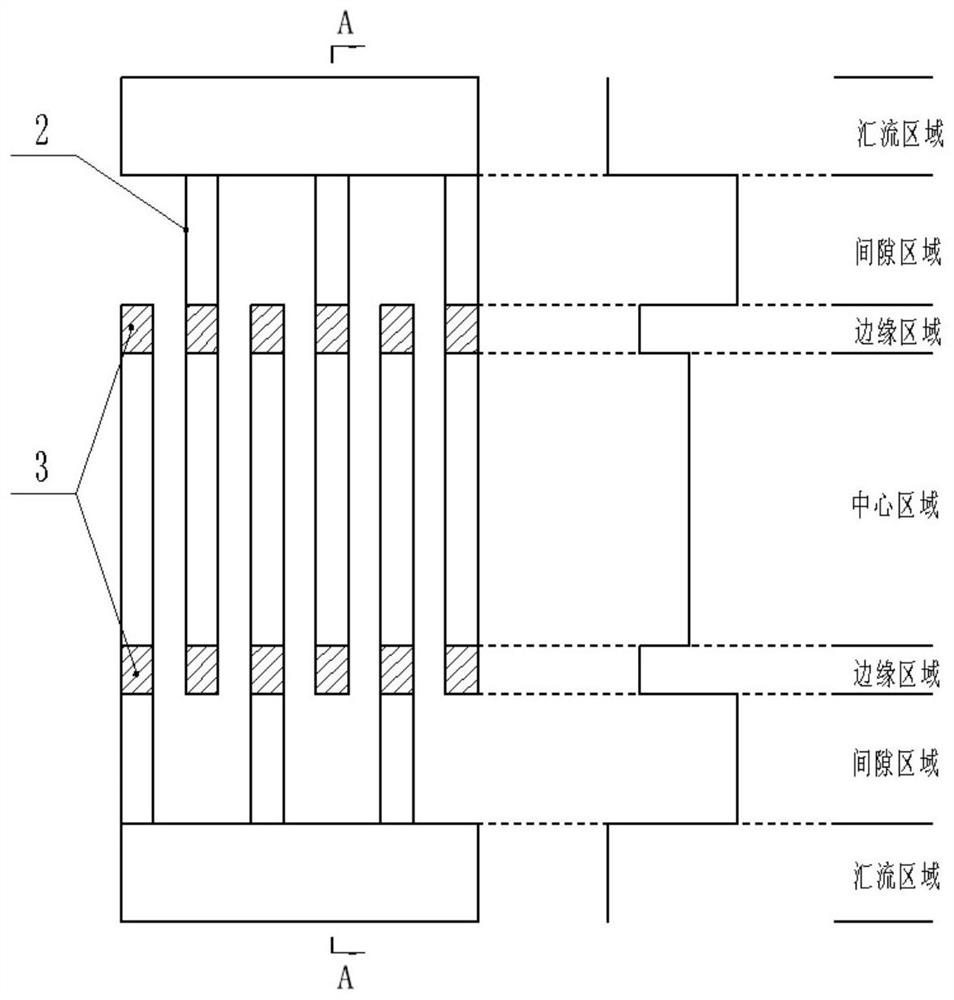

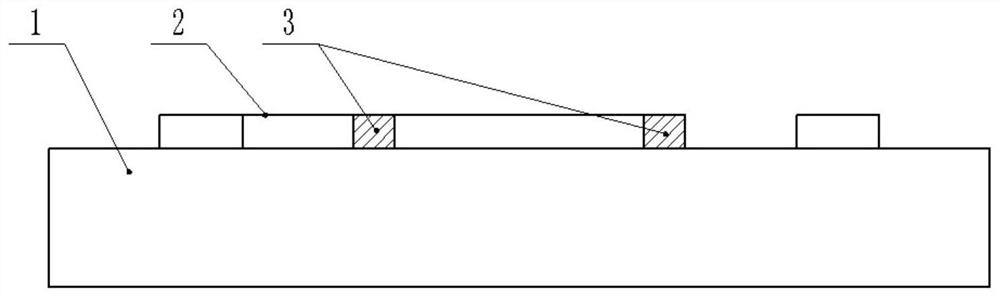

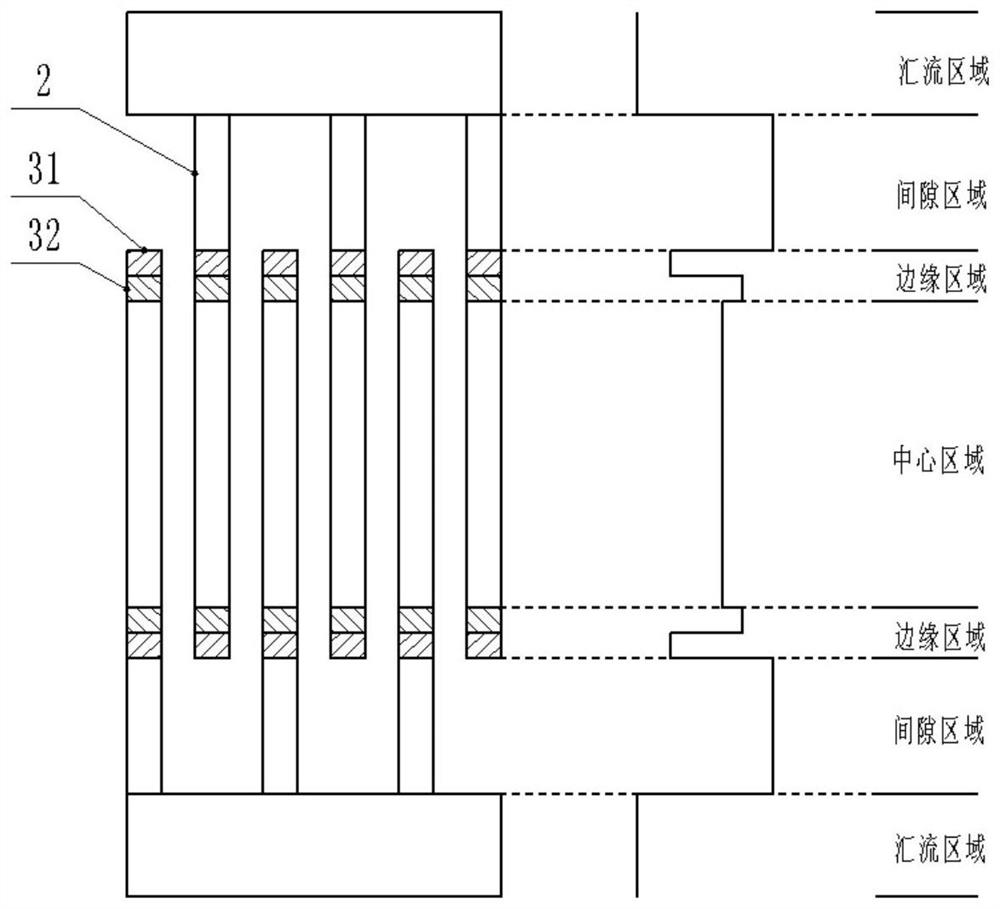

[0045] Example 1, such as figure 1 , figure 2As shown, a surface acoustic wave device capable of suppressing transverse modes includes an interdigital electrode 2 disposed on a piezoelectric substrate 1, and the edge region of the interdigital electrode 2 is provided with a material that is compatible with the main part of the interdigital electrode 2. Replacement part 3 with different densities.

[0046] Wherein, the interdigital electrode is divided into a main part and a replacement part according to different materials used. The replacement part can be arranged in the edge region. The edge area refers to the area of the interdigitated electrode close to the edge of the acoustic aperture (including the end of the electrode finger and the corresponding area on the adjacent finger bar along the direction of sound propagation), the inner side of which is the area where the sound wave mainly passes ( That is, the central area), and the outer side refers to the gap area be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com