High-mixing-strength aqueous film-forming foam extinguishing agent production device

A technology of foam fire extinguishing agent and mixing intensity, which is applied in the field of building decoration, can solve the problems of poor mixing effect and weak mixing intensity, and achieve the effect of increasing mixing intensity, increasing mixing reaction speed, and expanding mixing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

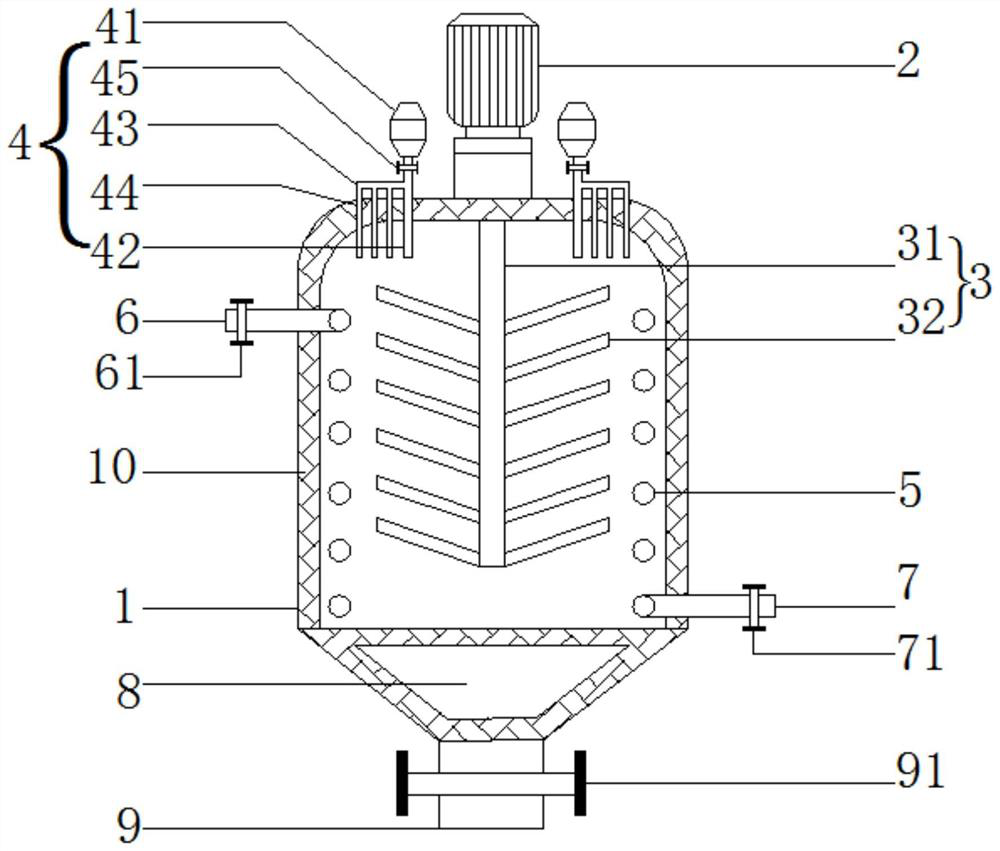

[0018] see figure 1 , the present invention provides a technical solution: a production device for an aqueous film-forming foam fire extinguishing agent with high mixing strength, comprising a kettle body 1, a rotating motor 2 is provided at the top of the kettle body 1, and the output end of the lower end 2 of the rotating motor runs through and connects to the kettle body 1 The inner cavity is provided with a stirring device 3, and the left and right ends of the rotary motor 2 are symmetrically provided with a feeding system 4, which increases the input amount of raw materials after premixing, improves the mixing efficiency, and improves the production capacity. The feeding system 4 includes a feeding pipe 41, and The material pipe 41 is fixedly connected with a main flow pipe 42, a part of the main flow pipe 42 runs through the inner cavity of the kettle body 1, a part of the main flow pipe 42 runs through and connects with the secondary flow pipe 43, and the lower end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com