VOC volatilization prevention device for sewage treatment pools and tanks

A sewage treatment tank, sewage tank technology, applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc., can solve the problem of damaged cover edge sealing, short cleaning cycle, poor sealing, etc. problem, to achieve the effect of oxygen barrier sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

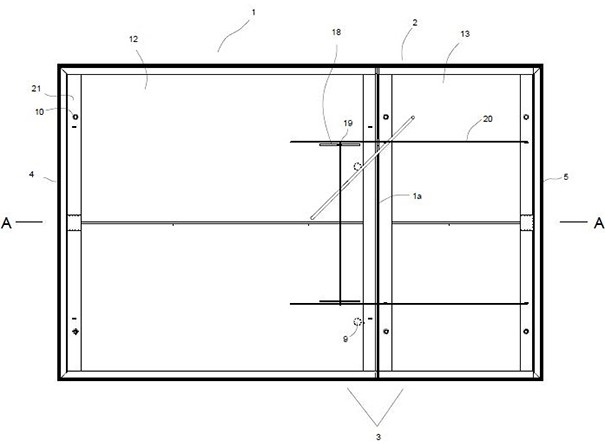

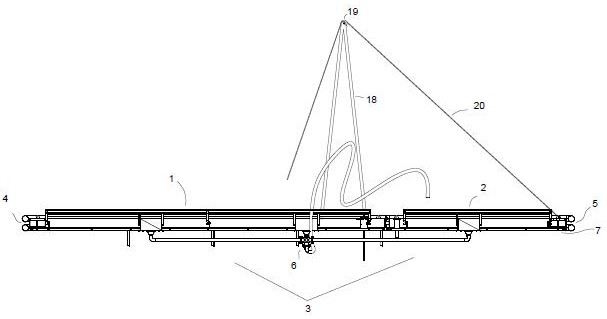

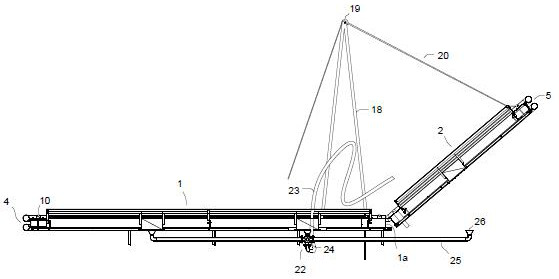

[0035] Depend on Figure 1 to Figure 3It can be seen from the anti-VOCs volatilization device shown that the fixed cover 1 and the connecting sides 1a and 2a of the movable cover 2 are hingedly matched, and the movable cover 2 can rotate in one direction around the hinge shaft; the fixed cover 1 and the movable cover 2 are both hollow The floating block structure, the two cooperate to form a complete square sealing suppression cover 3, the bottom surface of the square sealing suppression cover 3 is in hydraulic contact with the sewage treatment tank, based on the buoyancy of the square sealing suppression cover 3 itself, it floats on the liquid surface; The length of the cover plate 2 accounts for one-third of the square sealing restraint cover 3; the non-hinged joint edges of the movable cover plate 2 and the fixed cover plate 1 are provided with double-capsule-shaped sealing bodies 4, 5, sealing bodies 4, 5 is used to be in close contact with the inner wall of the sewage poo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com