Synthesis method of colloidal semiconductor sheet-shaped nanocrystal

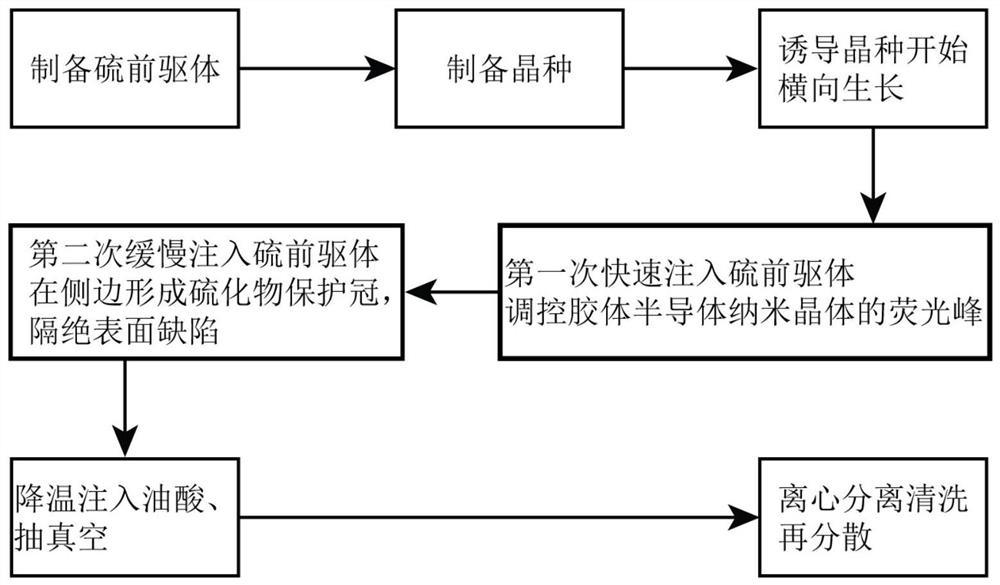

A nanocrystal and synthesis method technology, applied in nanotechnology, nanooptics, nanotechnology, etc., can solve the problems of uncontrollable fluorescence peak and low fluorescence quantum yield, so as to eliminate and isolate surface defects, isolate surface defects, and reduce complexity. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

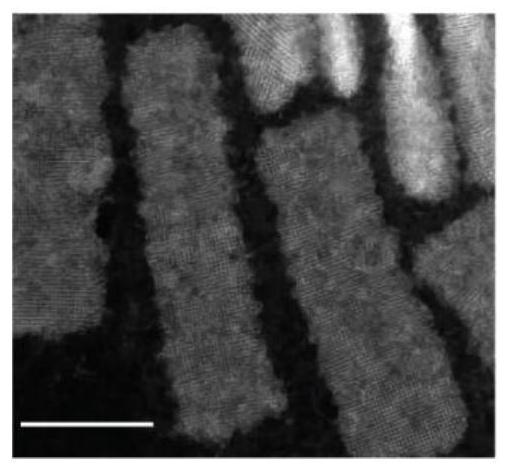

Image

Examples

Embodiment 1

[0024] The synthetic method of the colloidal semiconductor flaky nanocrystal of the present embodiment comprises the following steps:

[0025] 1) Preparation of sulfur precursor:

[0026]5 millimoles of sulfur element and 5 millimoles of oleic acid were added to 50 milliliters of octadecene organic solution, ultrasonically vibrated and mixed for 15 minutes to obtain a clear sulfur precursor, wherein the concentration of sulfur was 0.1 Moles per liter, the concentration of oleic acid is 0.1 moles per liter;

[0027] 2) Prepare the seed crystals of colloidal semiconductor flake nanocrystals:

[0028] Using the hot injection method, add 15 ml of octadecene, 0.3 mmol of cadmium myristate and a stirring magnet into the three-necked flask, and equip the three-necked flask with a temperature control device, a temperature detection device, a double-row tube and a magnetically controlled stirring Taiwan; wherein, the temperature control device heats or cools down the mixture in the r...

Embodiment 2

[0035] The synthetic method of the colloidal semiconductor flaky nanocrystal of the present embodiment comprises the following steps:

[0036] 1) Preparation of sulfur precursor:

[0037] 160 milligrams (5 millimoles) of sulfur element and 5 millimoles of oleic acid were added to the organic solution of 50 milliliters of octadecene, and ultrasonic vibration was mixed for 15 minutes to obtain a clarified sulfur precursor, to obtain a clarified sulfur precursor, wherein, The concentration of sulfur is 0.1 mole per liter, the concentration of oleic acid is 0.1 mole per liter;

[0038] 2) Prepare the seed crystals of colloidal semiconductor flake nanocrystals:

[0039] Using the hot injection method, add 15 ml of octadecene, 0.3 mmol of cadmium myristate and a stirring magnet into the three-necked flask, and equip the three-necked flask with a temperature control device, a temperature detection device, a double-row tube and a magnetically controlled stirring Taiwan; wherein, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com