Blade for cutting uranium mining casing and reaming ore-bearing and water-bearing stratum

A cutting tool and blade technology, which is applied in earthwork drilling, drilling equipment, wellbore/well parts, etc., can solve the problems that casing cutting and ore-bearing aquifer reaming cannot be applied at the same time, and the blade is easy to wear, etc., to achieve improved The effect of cutting efficiency, long service life and small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

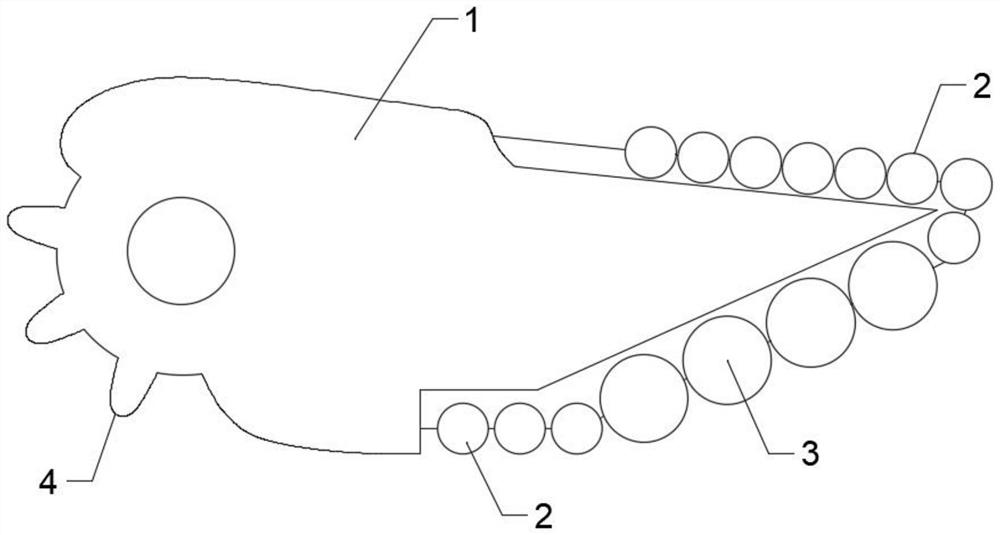

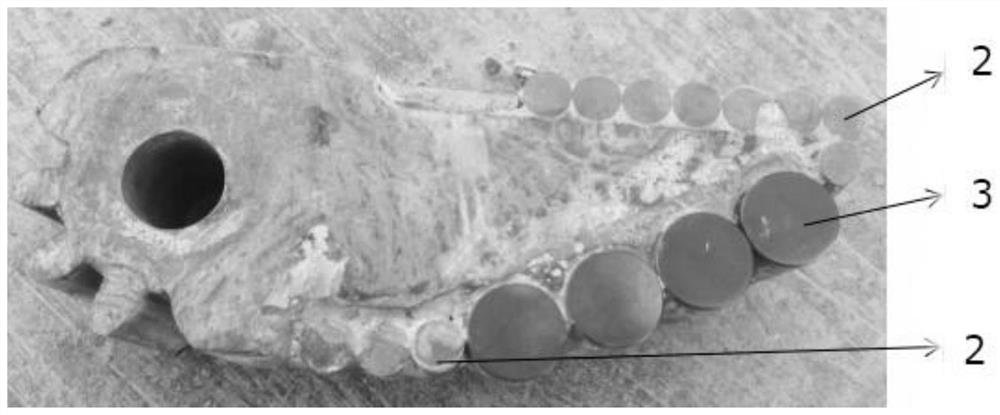

[0026] Such as figure 1 and figure 2 As shown, a blade for casing cutting of uranium mining and reaming of ore-bearing aquifers, the cutting edge of the blade 1 is composed of an alloy sheet 2 and a composite sheet 3, the alloy sheet 2 is located at the head and tail of the cutting edge of the blade 1, and the composite The sheet 3 is located in the middle of the cutting edge of the blade 1, the alloy sheet 2 and the composite sheet 3 are fixed on the blade 1 by welding, and the tail of the blade 1 is also provided with a locking tooth 4, such as image 3 and Figure 4 As shown, the blade 1 is equipped with a cutting tool, the cutting tool includes a housing 5, the housing 5 is provided with a liquid storage chamber 6, the bottom of the liquid storage chamber 6 is provided with a guide tube 7, and the guide tube 7 is covered with a plung...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com