Tunnel secondary lining concrete construction simulation system and simulation method

A technology of secondary lining and simulation system, applied in the direction of tunnel lining, tunnel, wellbore lining, etc., to achieve the effect of ensuring durability performance, comprehensive evaluation indicators, and ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1: A test was carried out with medium-fluidity lining concrete, and the concrete slump was 22.5 cm.

[0045] A tunnel secondary lining concrete construction simulation method, comprising the following steps:

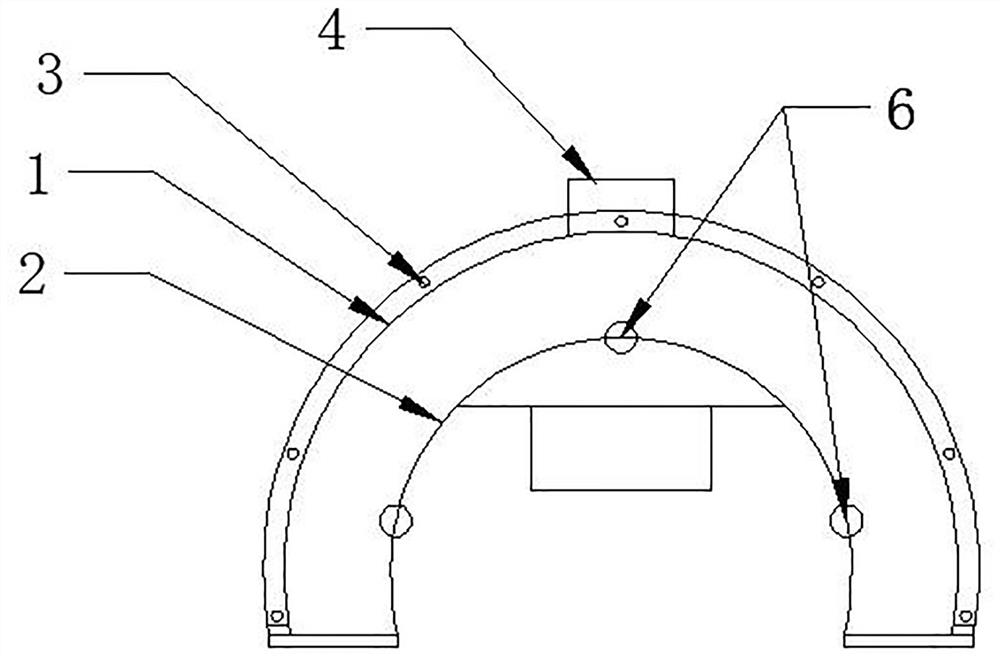

[0046] Step 1: Brush a layer of oil or release agent inside the inner arch formwork 2 and the outer arch formwork 1, and then fasten the inner and outer formworks with bolts and nuts.

[0047] Step 2: Divide the concrete into two parts. After one part is mixed, the arch waist pouring stage is performed, and timing is performed. During pouring, pouring is performed from the pouring port 4 of the outer arch formwork 1 .

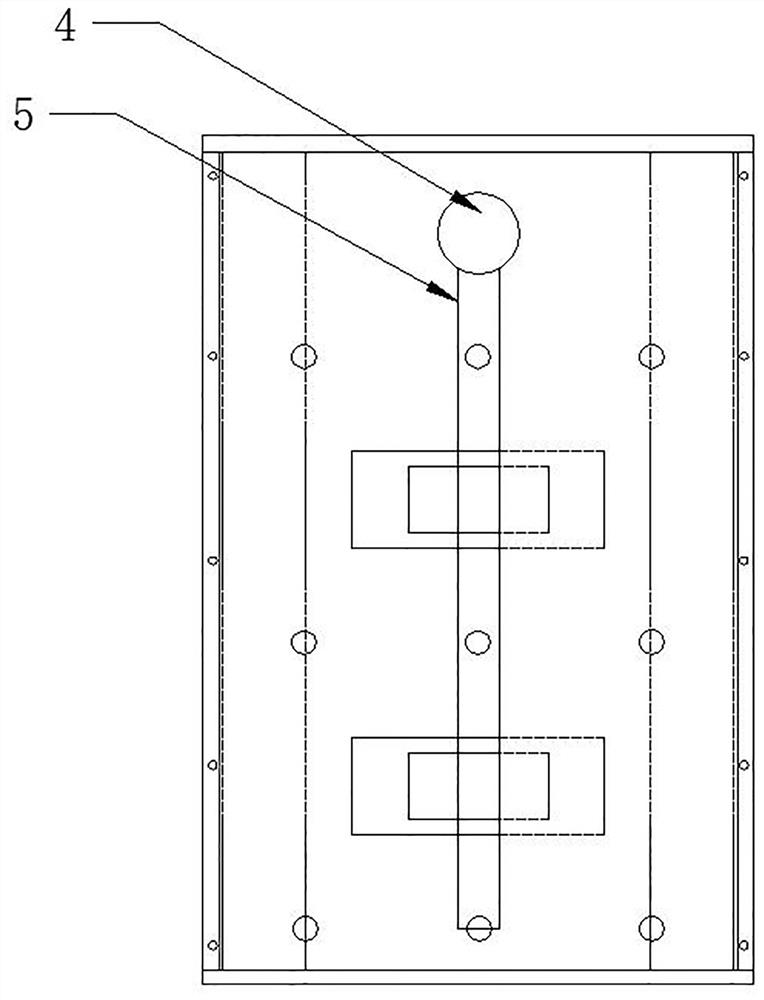

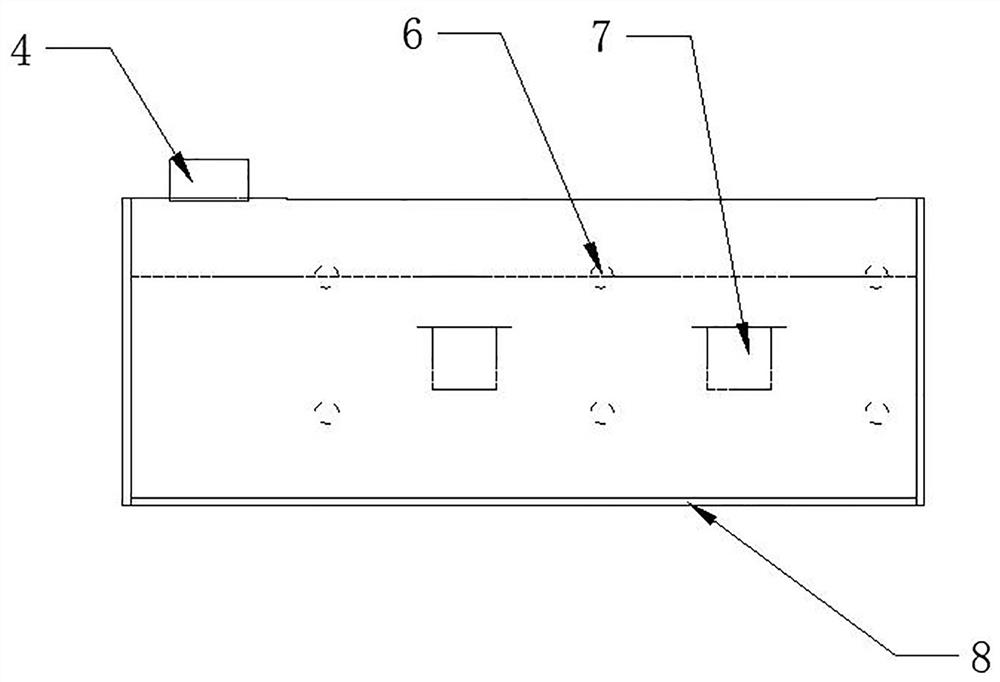

[0048] Step 3. After the pouring is completed, record the pouring time of the arch waist pouring stage, (such as Figure 5 ) and turn on the attached micro-vibrator 7 to vibrate the concrete, and observe the flow of the concrete from the observation port 5, stop vibrating when the concrete liquid level reaches the Figure 6 ).

[0049] Ste...

Embodiment 2

[0052] Example 2: A test was carried out using traditional lining concrete, and the concrete slump was 17cm.

[0053] The steps are the same as the above steps. After the concrete pouring is completed, export the data of the data collector, close the data collector, and obtain the pressure changes of the templates at each test point during the pouring process through data processing. ( Figure 8 , Figure 10 , Figure 12 )

[0054] Topographic photographs of conventionally lined concrete surfaces (e.g. Figure 14 , Figure 15 , Figure 16 , Figure 19 ),right Figure 19 Perform binarization analysis. (Such as Figure 20 )

[0055] The pouring and vibrating time, the pressure change of the lining formwork and the surface appearance of the lining concrete after hardening were used to evaluate the flow and filling effect of the lining concrete at different positions of the vault and the arch waist in the inner arch formwork 2 Performance of secondary lining concrete. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com