Automatic production line for charging firework paper tube cakes

An automatic production line and paper tube technology, applied in pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of unsafe operators, low efficiency, and slow speed, and achieve the effect of high automation, fast speed, and uniform drug mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

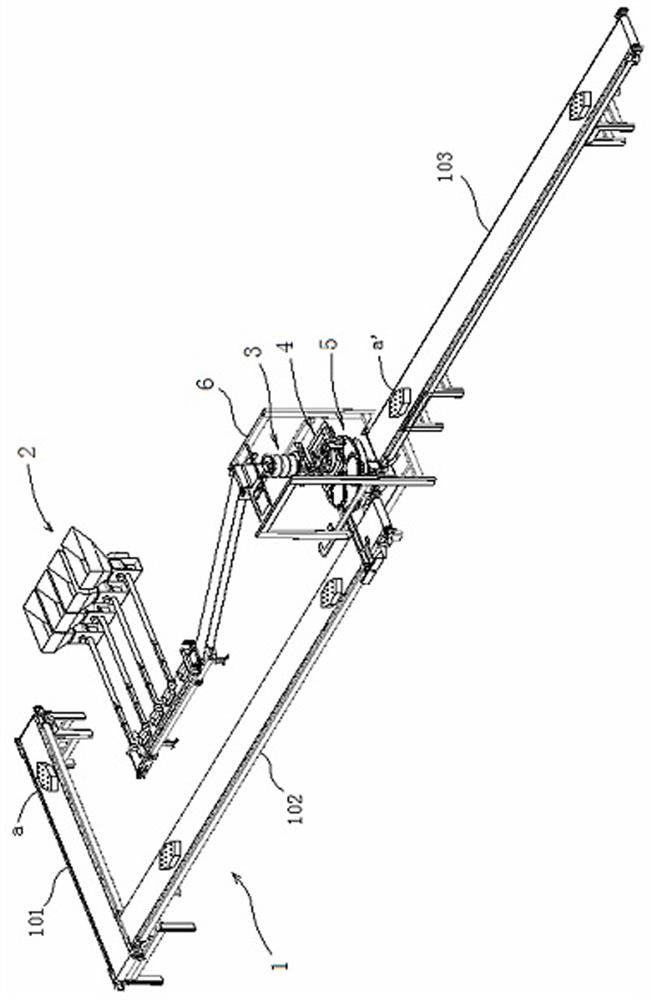

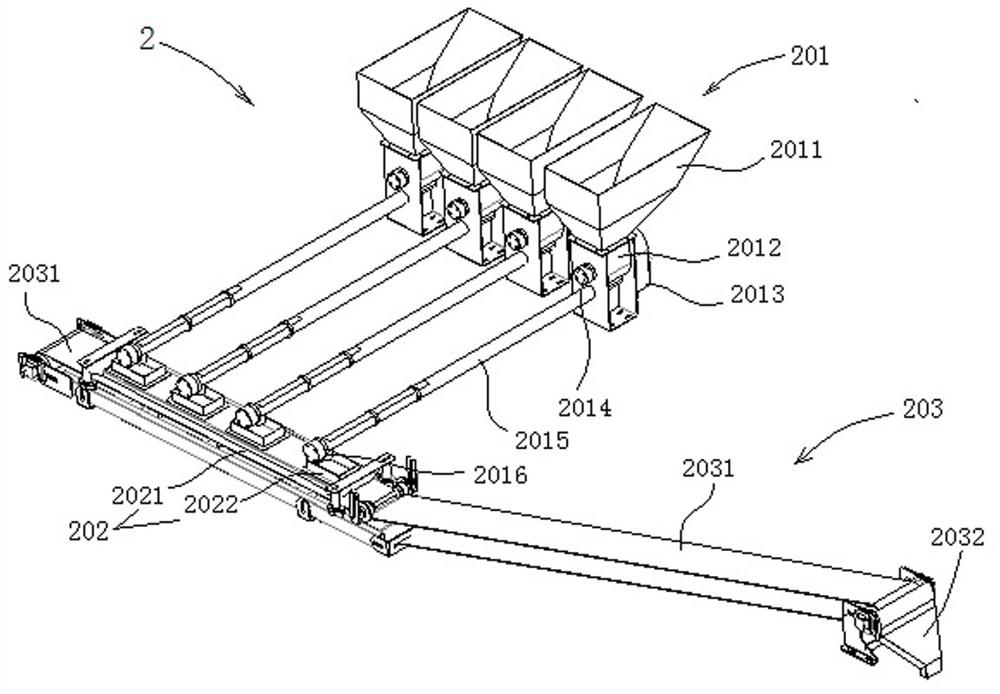

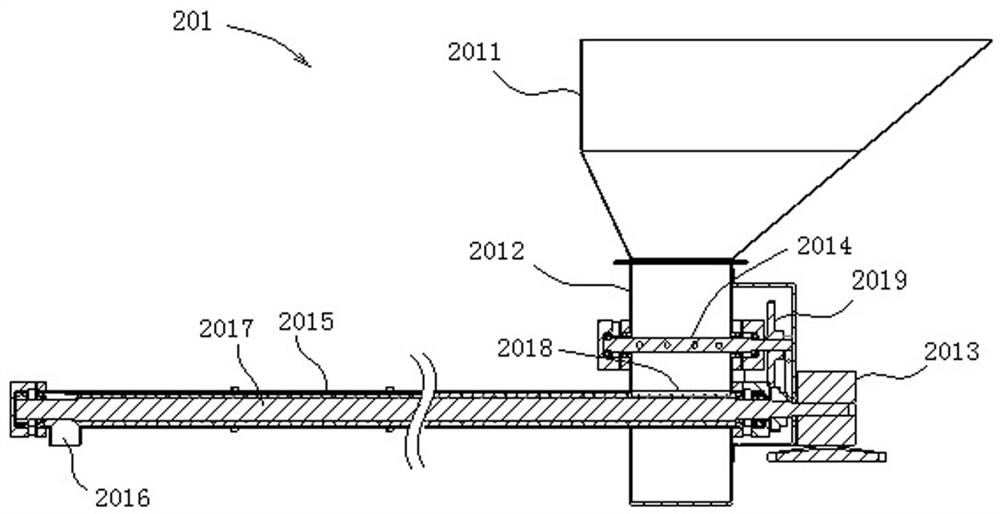

[0029] See figure 1 , Figure 4 , the firecracker paper tube cake filling automatic production line provided by the present invention comprises a fireworks paper tube cake conveying device 1, a medicine ingredient conveying device 2 arranged on one side of the firecracker paper tube cake conveying device 1, and a medicine ingredient conveying device 2 through a feed port 302. The drug mixing device 3 connected to the device 2, the charge metering device 4 corresponding to the discharge port 303 of the drug mixing device 3, is arranged under the charge metering device 4 to cooperate with the charge metering device 4 and is connected to the firecracker paper tube cake conveying device 1 The connecting firecracker paper tube cake rotary drug receiving device 5 is electrically connected with the fireworks paper tube cake delivery device 1, the drug ingredient delivery device 2, the drug mixing device 3, the charge quantitative device 4, and the fireworks paper tube cake rotary dru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com