Vehicle armrest torque testing device

A technology of torque testing and handrails, which is applied in the direction of measuring devices, torque measurement, and measuring fluid pressure, etc. It can solve the problems of popping up and hurting people, and the rotating end is easy to fall off, so as to prevent the handrail from popping up, save test time, and fix the rotating end. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050]The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

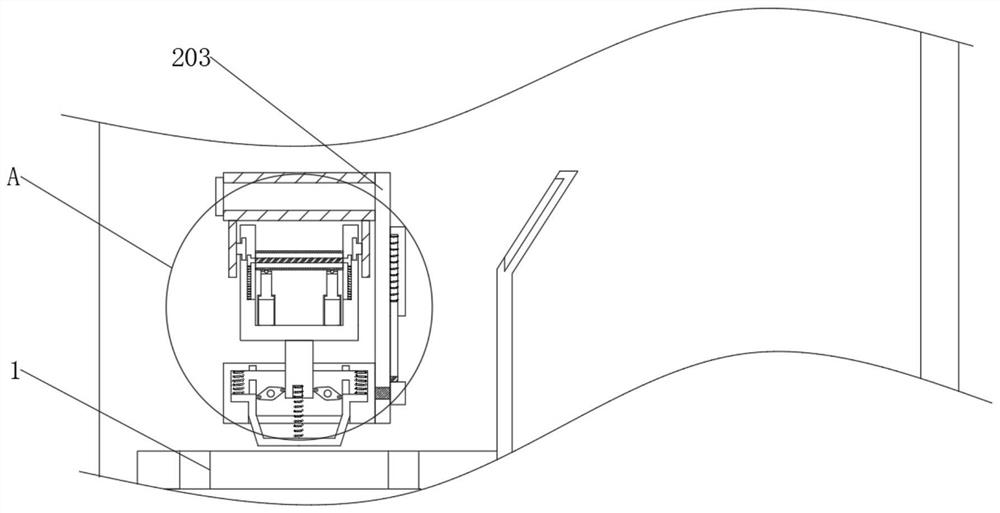

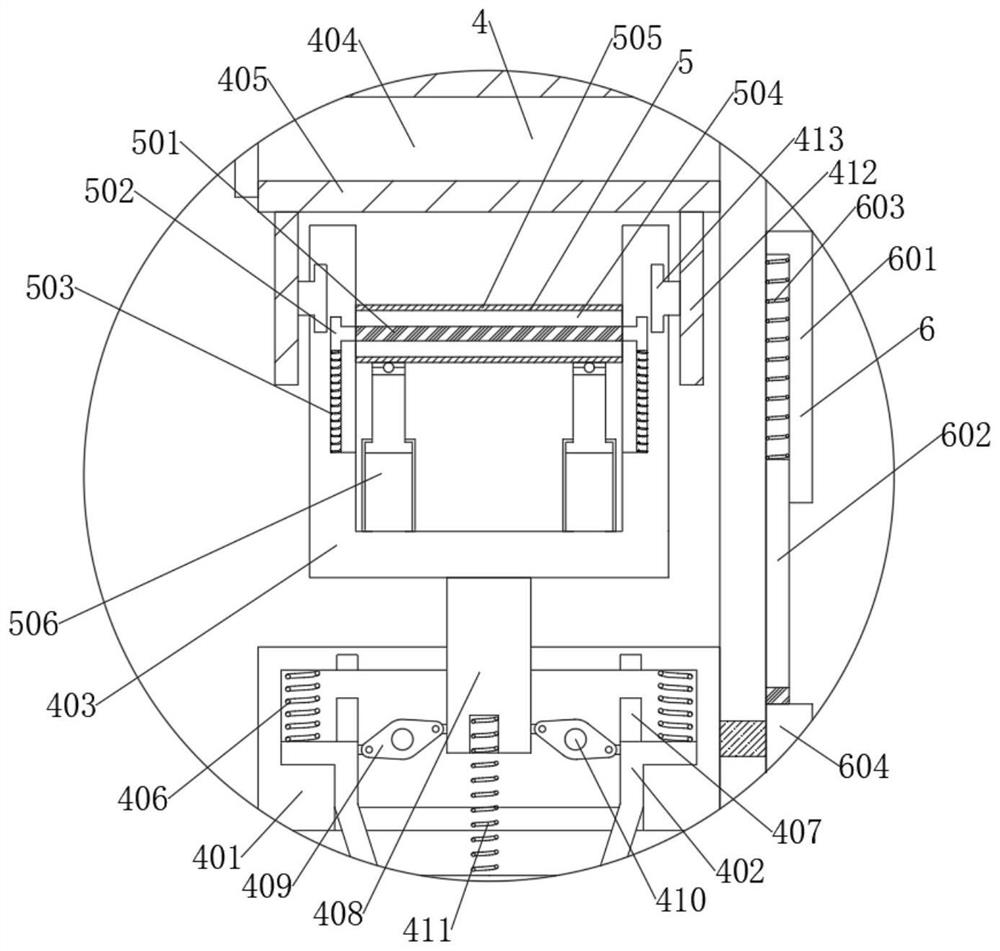

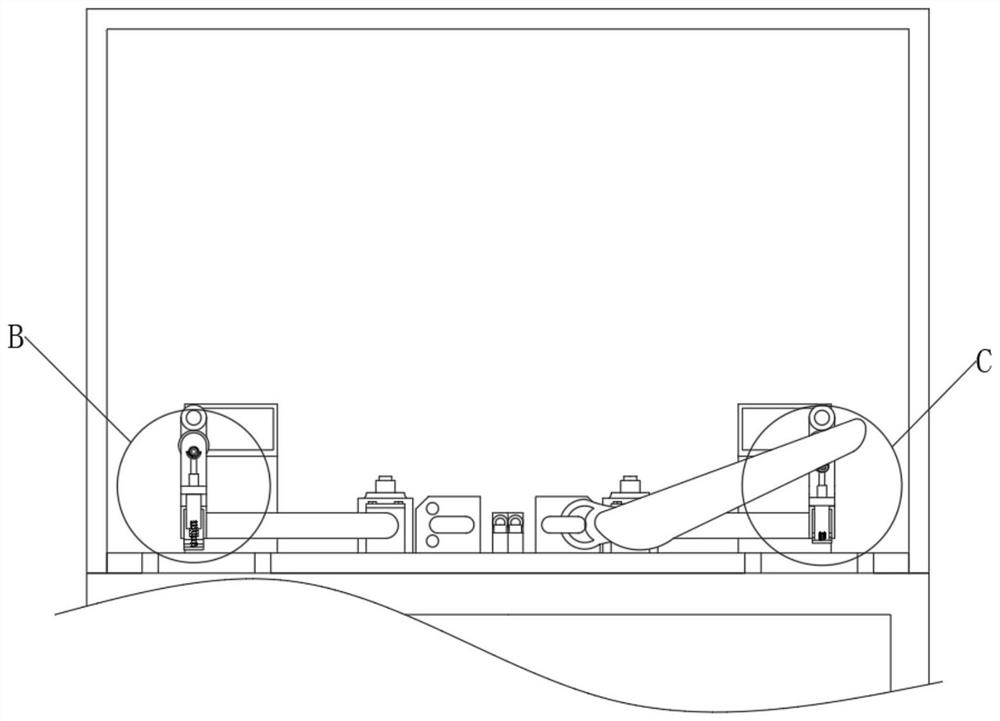

[0051] The invention discloses a vehicle armrest torque testing device, referring to Figure 1-Figure 8 As shown, it includes a workbench 1 , a rotating section clamping mechanism 4 , an adaptive clamping mechanism 5 , a safety mechanism 6 , a pair of torque testing mechanisms 2 and a pair of fixed end clamping mechanisms 3 .

[0052] ginseng Figure 6-Figure 8 As shown, a pair of torque testing mechanism 2 is provided on the workbench 1 for testing the torque. The torque testing mechanism 2 includes a motor 201, and the motor 201 is used to drive the rotation of the test follower rod 203, and can pass the test follower...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap