Tensile force detection apparatus for high-resistance diaphragm interlayer and operating method of tensile force detection apparatus

A technology of tension detection and diaphragm layer, which is applied in the direction of measuring devices, mechanical devices, force/torque/work measuring instruments, etc., can solve the problems of low accuracy of test results, low stability of high-barrier membranes, and poor safety and other issues to achieve the effect of improving safety, avoiding shaking and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

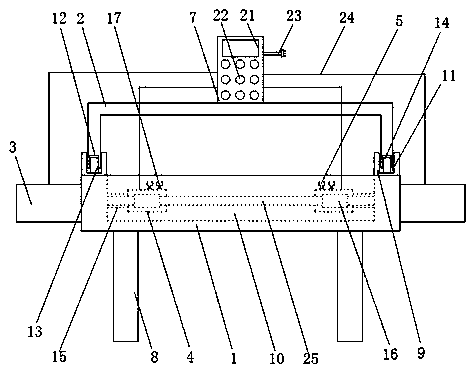

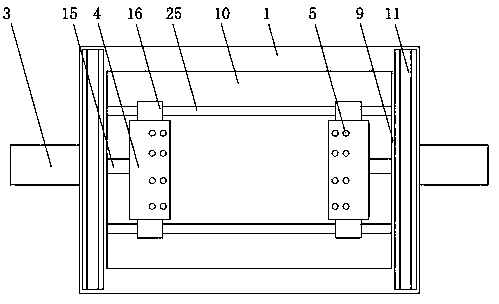

[0023] as attached Figure 1-4 Shown: a tension detection device for interlayers of high-barrier membranes, including an operating table 1, a protective plate 2, a cylinder 3, a pull block 4, an adjusting screw 5, a pressing plate 6 and a controller 7, characterized in that: The operating table 1 is arranged on the support 8, the positioning block 9 is arranged on the operating table 1, and the fixing groove 10 is arranged on the operating table 1 between the positioning block 9 and the positioning block 9, and the positioning block 9 A positioning groove 11 is provided, a slide bar 25 is arranged in the fixed groove 10, both ends of the protective plate 2 are arranged in the positioning groove 11, and the cylinder 3 is arranged on opposite sides of the console 1. 3 is provided with a piston rod 15, and the piston rod 15 and the sliding rod 25 are arranged in the fixed groove 10 parallel to each other. The opposite sides of the pull block 4 are provided with slide blocks 16, a...

Embodiment 2

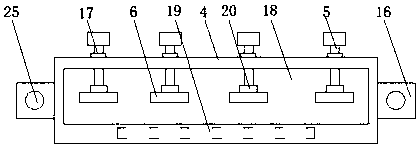

[0034] as attached Figure 5 Shown: a tension detection device for interlayers of high-barrier membranes, including an operating table 1, a protective plate 2, a cylinder 3, a pull block 4, an adjusting screw 5, a pressing plate 6 and a controller 7, characterized in that: The operating table 1 is arranged on the support 8, the positioning block 9 is arranged on the operating table 1, and the fixing groove 10 is arranged on the operating table 1 between the positioning block 9 and the positioning block 9, and the positioning block 9 A positioning groove 11 is provided, a slide bar 25 is arranged in the fixed groove 10, both ends of the protective plate 2 are arranged in the positioning groove 11, and the cylinder 3 is arranged on opposite sides of the console 1. 3 is provided with a piston rod 15, and the piston rod 15 and the sliding rod 25 are arranged in the fixed groove 10 parallel to each other. The opposite sides of the pull block 4 are provided with slide blocks 16, and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap